A kind of elution column and its elution method for whole fraction coal tar

A technology of elution tower and coal tar, which is applied in the field of elution tower, can solve problems such as inadaptability to dehydration of coal tar, instability of viscous properties, and influence on normal operation of the tower, so as to avoid sticking and coking, good Economic benefits, the effect of avoiding the phenomenon of tower flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

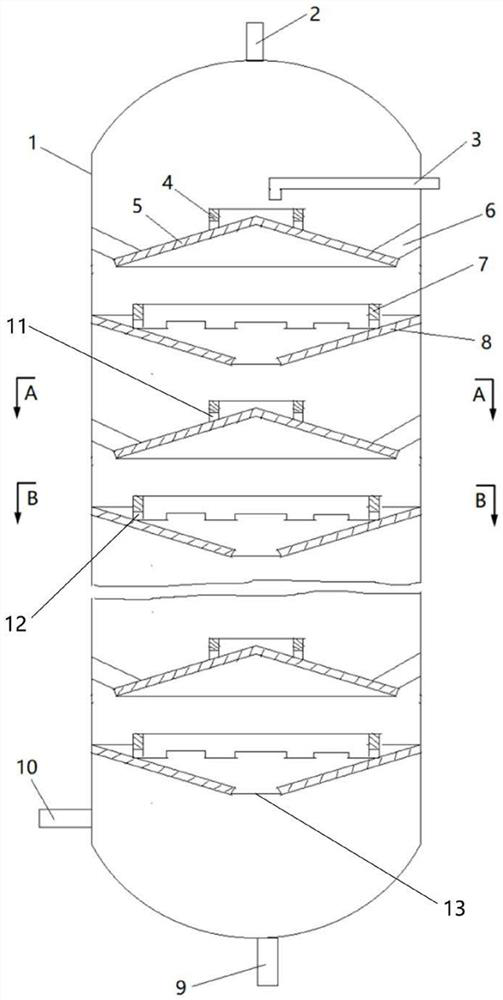

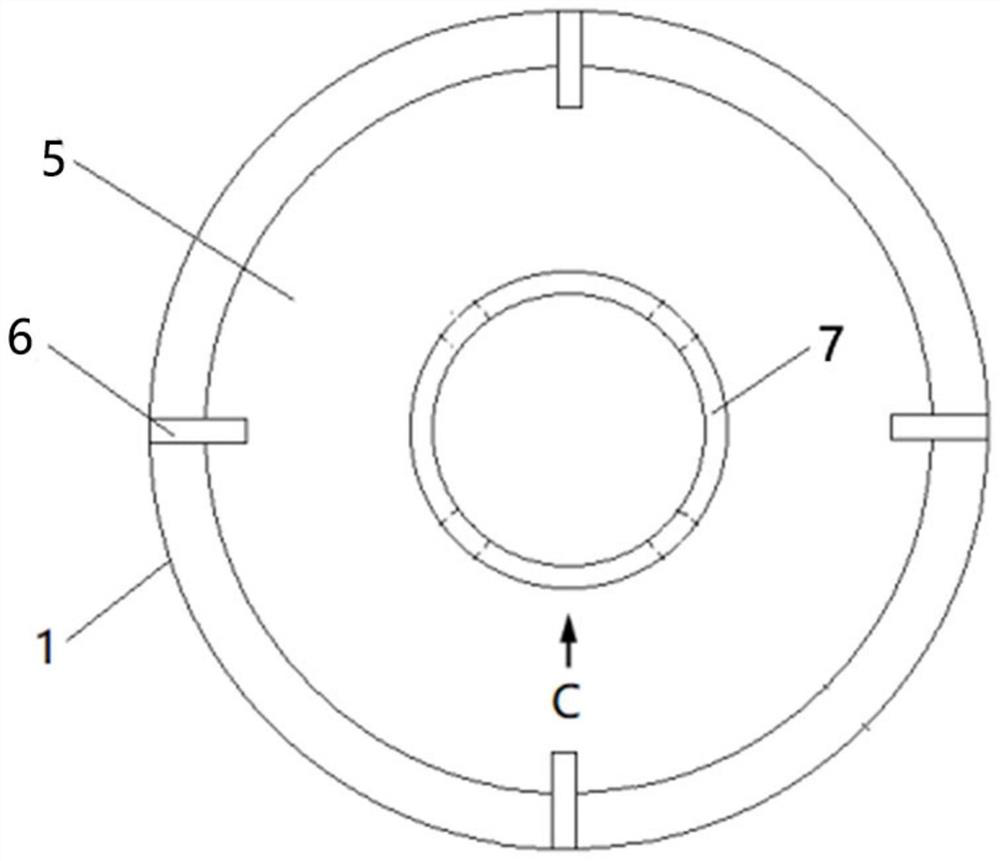

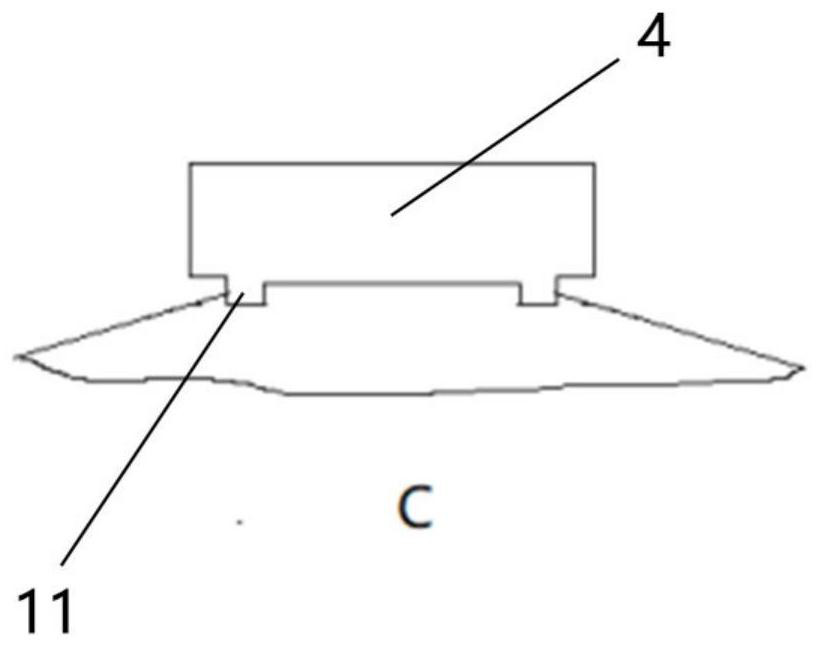

[0032] Such as Figure 1-4 As shown, the present embodiment provides a schematic structural diagram of an elution tower, including a tower body 1, a liquid inlet 3 and a gas outlet 2 are provided on the top of the tower body 1, wherein the liquid inlet 3 extends to the uppermost dispersing plate in the tower In the liquid collection area; the bottom of the tower body 1 is provided with a liquid outlet 9 and a gas inlet 10; the tower body 1 is provided with 10 sets of dispersing plates, and each set of dispersing plates includes umbrella-shaped dispersing plates 5 distributed up and down And the bucket-shaped dispersion plate 8, there is a gap between the umbrella-shaped dispersion plate 5 and the side wall of the tower body 1, and the lower end of the bucket-shaped dispersion plate 8 is provided with an opening 13.

[0033] In this embodiment, the umbrella-shaped dispersing plate 5 is a right conical steel plate, installed in the center of the tower, and there are four connect...

Embodiment 2

[0040] The present embodiment provides a method for elution of full fraction coal tar using the elution tower of Embodiment 1, implemented in a coal company in Hami, Xinjiang, comprising the following steps:

[0041] (1) Heating treatment: use a heat exchanger to heat the coal tar to 170°C, and send it into the elution tower from the liquid inlet;

[0042] (2) Nitrogen is passed into the tower: feed nitrogen into the tower from the gas inlet, the amount of nitrogen feed is 1.5% of the full fraction coal tar tower charge, thereby reducing the partial pressure of each component in the full fraction coal tar, so that it evaporates at a lower boiling temperature;

[0043] (3) System vacuuming: adopt vacuum pump to vacuumize, and the vacuum degree is 0.08Mpa, so that moisture, dissolved oxygen, and low-boiling point phenolic compounds are evaporated from the tower top;

[0044] (4) Separation of distillate at the top of the tower: the distillate at the top of the tower enters the ...

Embodiment 3

[0049] The present embodiment provides a method for elution of full-fraction coal tar using the elution tower of Embodiment 1, which is implemented in B Coal Enterprise in Hami, Xinjiang, including the following steps:

[0050] (1) Heating treatment: use a heat exchanger to heat the coal tar to 200°C, and send it into the elution tower from the liquid inlet;

[0051] (2) pass into nitrogen in the tower: pass into nitrogen in the tower from gas inlet, nitrogen feed rate is the 2.0% of full cut coal tar tower feed, thereby reduces the partial pressure of each component in the full cut coal tar, so that It distills off at a lower boiling temperature;

[0052] (3) System vacuuming: adopt vacuum pump to vacuumize, and the vacuum degree is 0.085Mpa, so that moisture, dissolved oxygen, and low-boiling point phenolic compounds are evaporated from the tower top;

[0053] (4) Separation of distillate at the top of the tower: the distillate at the top of the tower enters the cooler from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com