Washing powder

A powder and adhesive technology, applied in the directions of detergent compounding agent, detergent composition, detergent powder/flake/sheet, etc., can solve the problems of agglomeration, poor fluidity of powder, etc. Good granulation, good emulsification and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In one of the specific embodiments, the preparation method of the component A and / or the component B comprises the following steps:

[0033] adding water to the binder to make a binder solution;

[0034] Soda ash or sodium sulfate is granulated with the binder solution and dried.

[0035] More specifically, the mass concentration of the binder in the binder solution is 0.5-20%.

[0036] More specifically, the drying temperature is 80-95° C., and the drying time is 1-8 hours.

[0037] More specifically, the water is first heated to 50-80° C., then the binder is added and stirred to dissolve.

[0038] In one specific embodiment, the copolymer dispersant is one or more of vinyl monomer copolymers containing carboxylic acid groups or containing sulfonic acid groups. The use of this type of copolymer dispersant is beneficial to the uniform dispersion of soda ash and sodium sulfate in the system for adhesive bonding, good fluidity and stable detergency.

[0039] In one sp...

Embodiment 1~4

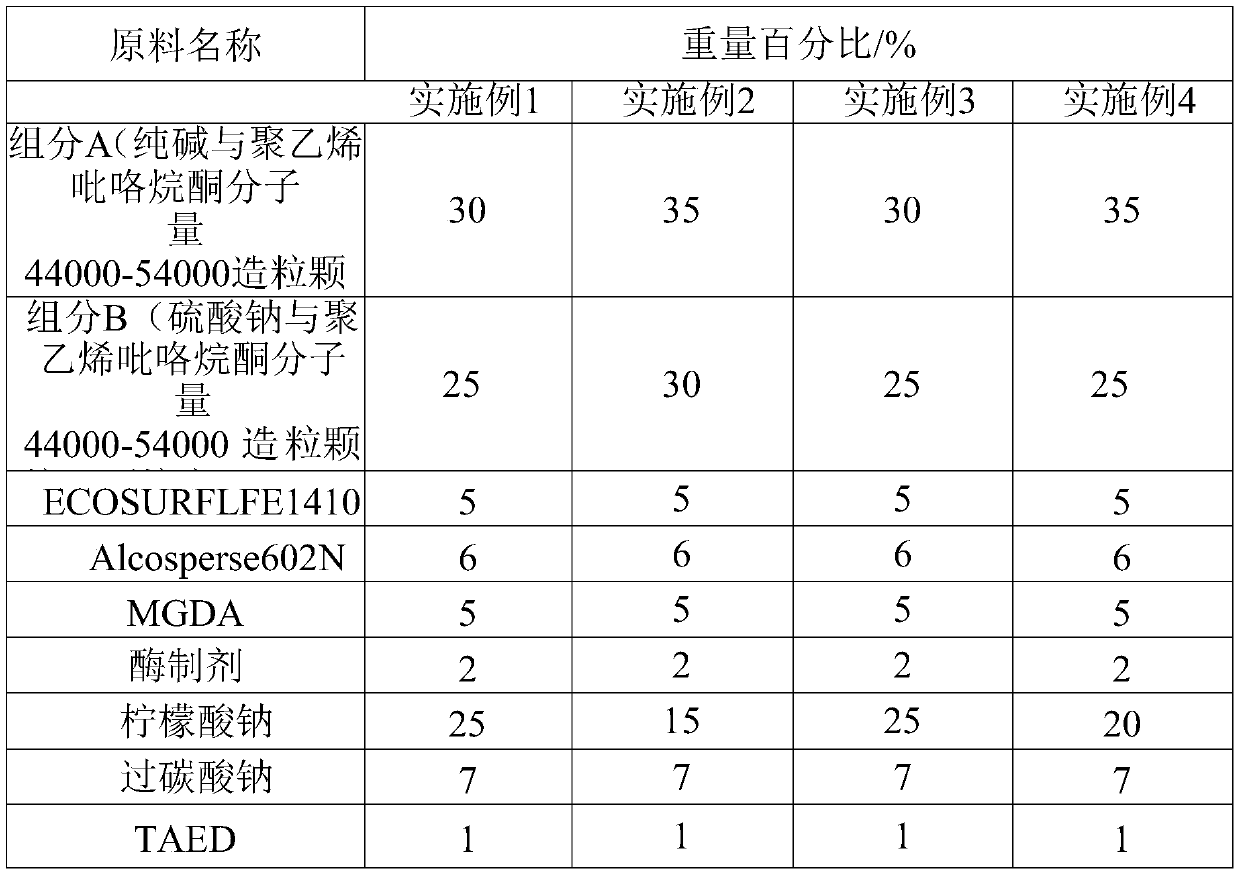

[0057] According to the formula table in Table 1, Examples 1-4 were prepared respectively to prepare a special detergent powder for household dishwashers with high fluidity. Its preparation method comprises the following steps:

[0058] According to the feeding ratio, component A, component B, sodium percarbonate, enzyme preparation, ethylene oxide and propylene oxide block copolymer surfactant ECOSURFLFE1410, carboxylic acid group-containing copolymer dispersant Alcosperse602, etc. Mixing; Stir the mixed material evenly, take a sample for testing, and fill it if it passes the test.

[0059] The formula composition of the household dishwasher special washing powder with high fluidity of table 1 embodiment 1~4

[0060]

Embodiment 5~8

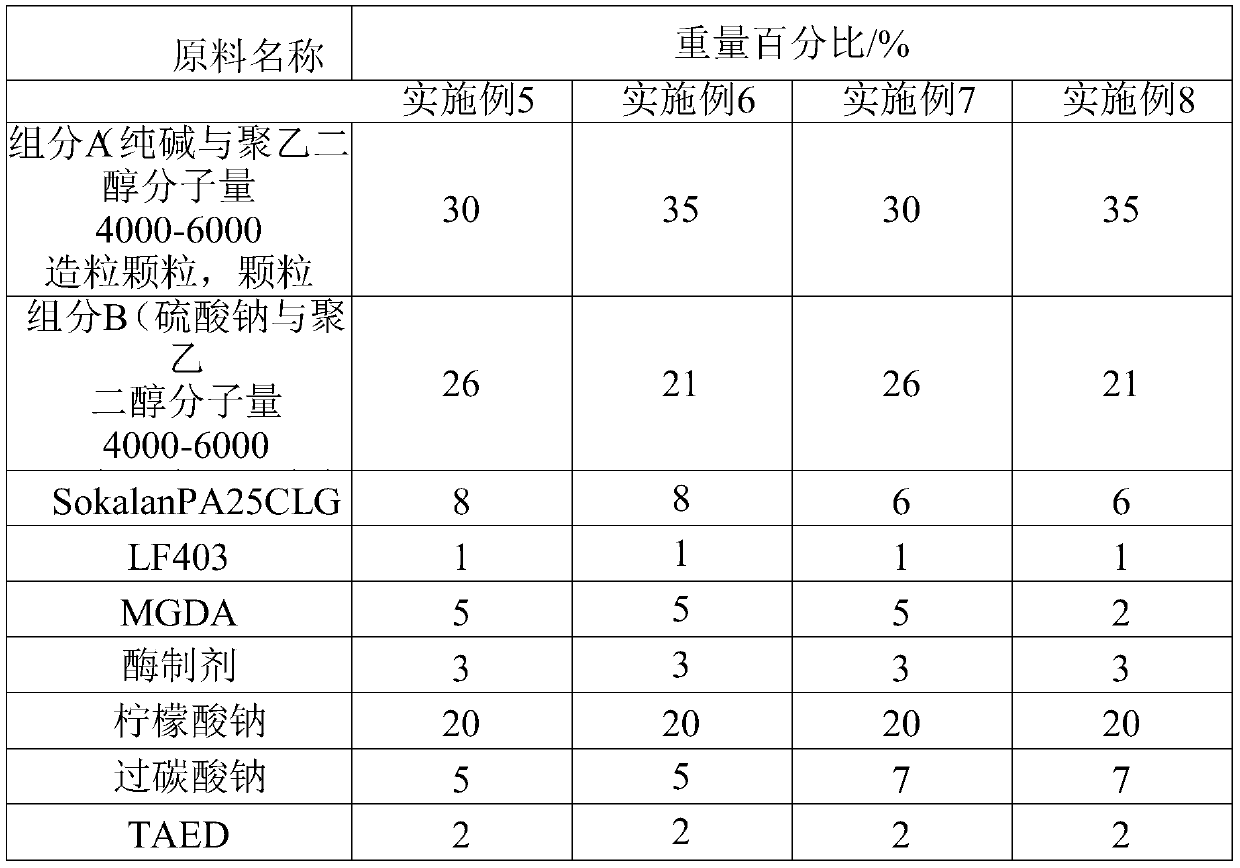

[0062] According to the formula table in Table 2, Examples 5-8 were prepared respectively to prepare the special detergent powder for household dishwashers with high fluidity. Its preparation method comprises the following steps:

[0063] Mix component A, component B, sodium percarbonate, enzyme preparation, polyoxyethylene compound surfactant LF403, copolymer dispersant SokalanPA25CLG containing carboxylic acid groups, etc. according to the feeding ratio; stir the mixed material evenly, Sampling and testing, the inspection is qualified, and the filling is carried out.

[0064] The formula composition of the household dishwasher special washing powder with high fluidity of table 2 embodiment 5~8

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com