Preparation technology of high-purity recombinant tumor necrosis factor-related apoptosis-inducing ligand (TRAIL)

A preparation process and high-purity technology, applied in the field of preparation of high-purity recombinant TRAIL, can solve the problems of changes in the culture system, affecting the yield and purity of TRAIL, and achieve good chromatographic separation, increase yield and purity, and increase separation. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

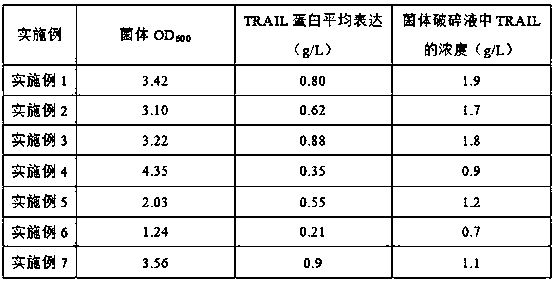

Examples

Embodiment 1

[0043] Step 1: Add 5% of the frozen culture solution into the medium shake flask, and stir at 180 rpm and 37°C for 1 hour.

[0044] Wherein, the culture solution, in terms of mass concentration, includes the following components: tryptone 27g / L; yeast extract 9g / L; acid hydrolyzed casein 9g / L; glucose 10g / L; calcium chloride 0.5g / L Sodium chloride 0.8g / L; Sodium dihydrogen phosphate 8 g / L; Ferrous acetate 0.035g / L; Defoamer 1g / L; Proper amount of acetic acid, adjust the pH to 6.5.

[0045] Step 2: Inoculate the Escherichia coli containing the recombinant plasmid of the recombinant TRAIL gene at a ratio of 1% into the obtained culture medium shake flask; rotate at 220 rpm and culture at 36° C. for fermentation.

[0046] Wherein, the Escherichia coli preparation process of the recombinant TRAIL gene fragment includes the following steps: Step 1, the construction of the target gene, using human pancreatic tissue cDNA as a template to perform PCR amplification from the tryptophan ...

Embodiment 2

[0051] Step 1: Inject the frozen culture solution into the medium shake flask at a ratio of 1%, and stir at 100 rpm and 30° C. for 1 hour.

[0052] Wherein, the culture solution includes the following components in terms of mass concentration: tryptone 20g / L; yeast extract 8g / L; acid hydrolyzed casein 12 g / L; glucose 8 g / L; calcium chloride 0.01 g / L; sodium chloride 0.5 g / L; sodium dihydrogen phosphate 5 g / L; ferrous acetate 0.02 g / L; defoamer 1 g / L; appropriate amount of acetic acid, adjust the pH to 6.8.

[0053] Step 2: Inoculate the Escherichia coli containing the recombinant plasmid of the recombinant TRAIL gene at a ratio of 0.5% into a culture medium shake flask; ferment and culture at 200 rpm and a temperature of 30°C.

[0054] Wherein, the Escherichia coli preparation process of the recombinant TRAIL gene fragment includes the following steps: Step 1, the construction of the target gene, using human pancreatic tissue cDNA as a template to perform PCR amplification fr...

Embodiment 3

[0059] Step 1: Add 5% of the frozen culture solution into the medium shake flask, and stir at 200 rpm and 40°C for 0.5 hours.

[0060] Wherein, the culture solution includes the following components in terms of mass concentration: tryptone 40g / L; yeast extract 12g / L; acid hydrolyzed casein 8g / L; glucose 12 g / L; calcium chloride 0.5 g / L L; sodium chloride 1.0 g / L; sodium dihydrogen phosphate 10 g / L; ferrous acetate 0.05 g / L; defoamer 1 g / L; appropriate amount of acetic acid, adjust the pH to 5.5.

[0061] Step 2: Inoculate Escherichia coli containing the recombinant plasmid of the recombinant TRAIL gene at a rate of 10% into a culture medium shake flask; ferment culture at 250 rpm and 40°C.

[0062]Wherein, the Escherichia coli preparation process of the recombinant TRAIL gene fragment includes the following steps: Step 1, the construction of the target gene, using human pancreatic tissue cDNA as a template to perform PCR amplification from the tryptophan promoter, gene h-TRAIL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com