A kind of aluminum alloy surface nickel plating process

A technology of aluminum alloy surface and aluminum alloy, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of poor wear resistance, difficulty, negative electrode potential, etc., and improve the flatness and smoothness of the coating The effect of preventing small sand holes from missing plating and preventing the coating from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

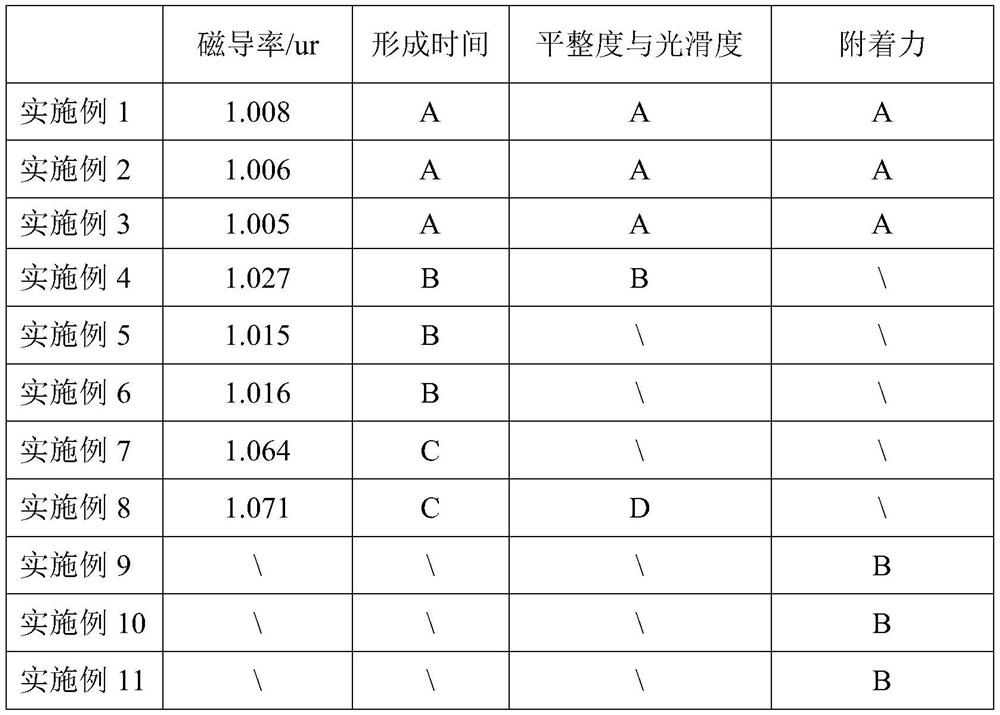

Embodiment 1

[0068] Embodiment 1 of the present invention provides an aluminum alloy workpiece containing a nickel-plated layer, and the plating process of the nickel-plating solution on the surface of the aluminum alloy sequentially includes the following steps:

[0069] (1) Degreasing: the aluminum alloy workpiece is placed in a degreasing tank containing an alkaline reagent for 8 min at 50-55 °C; the alkaline reagent is an aqueous sodium hydroxide solution; the concentration of sodium hydroxide is 50wt%;

[0070] (2) Desiliconization: the aluminum alloy workpiece obtained in step (1) is then placed in a desiliconization tank containing a strong oxidant for 60s at 25-30°C; the strong oxidant is an aqueous hydrogen peroxide solution, and the concentration of hydrogen peroxide is 65mL / L;

[0071] (3) The first deposition of zinc and nickel: the aluminum alloy workpiece obtained in step (2) is immersed in a mixed aqueous solution containing nickel ions for the first deposition of zinc and nic...

Embodiment 2

[0083] Embodiment 2 of the present invention provides an aluminum alloy workpiece containing a nickel-plated layer, and the plating process of the nickel-plating solution on the surface of the aluminum alloy sequentially includes the following steps:

[0084] (1) Degreasing: place the aluminum alloy workpiece in a degreasing tank containing an alkaline reagent for 8 min at 50-55 °C; wherein the alkaline reagent is an aqueous sodium hydroxide solution; the concentration of sodium hydroxide is 75wt%;

[0085] (2) Desiliconization: the aluminum alloy workpiece obtained in step (1) is then placed in a desiliconization tank containing a strong oxidant for 60s at 25-30°C; the strong oxidant is an aqueous hydrogen peroxide solution, and the concentration of hydrogen peroxide is 65mL / L;

[0086] (3) The first deposition of zinc and nickel: the aluminum alloy workpiece obtained in step (2) is immersed in a mixed aqueous solution containing nickel ions for the first deposition of zinc a...

Embodiment 3

[0098] Embodiment 3 of the present invention provides an aluminum alloy workpiece containing a nickel-plated layer, and the plating process of the nickel-plating solution on the surface of the aluminum alloy sequentially includes the following steps:

[0099] (1) Degreasing: place the aluminum alloy workpiece in a degreasing tank containing an alkaline reagent for 8 min at 50-55 °C; wherein the alkaline reagent is an aqueous sodium hydroxide solution; the concentration of sodium hydroxide is 65wt%;

[0100] (2) Desiliconization: the aluminum alloy workpiece obtained in step (1) is then placed in a desiliconization tank containing a strong oxidant for 60s at 25-30°C; the strong oxidant is an aqueous hydrogen peroxide solution, and the concentration of hydrogen peroxide is 65mL / L;

[0101] (3) The first deposition of zinc and nickel: the aluminum alloy workpiece obtained in step (2) is immersed in a mixed aqueous solution containing nickel ions for the first deposition of zinc a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com