Rust remover and preparation method and application thereof

A rust remover and polyoxyethylene ether technology, applied in the field of iron and steel rust removal, can solve the problems of low rust removal efficiency, accelerated rust removal efficiency, metal surface corrosion, etc., to improve rust removal efficiency and rust removal speed, waste liquid The effect of reducing the amount of production and increasing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

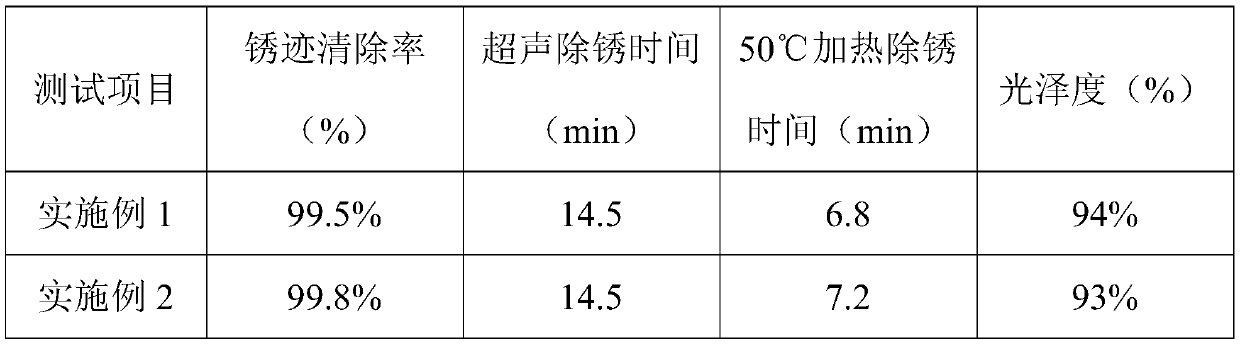

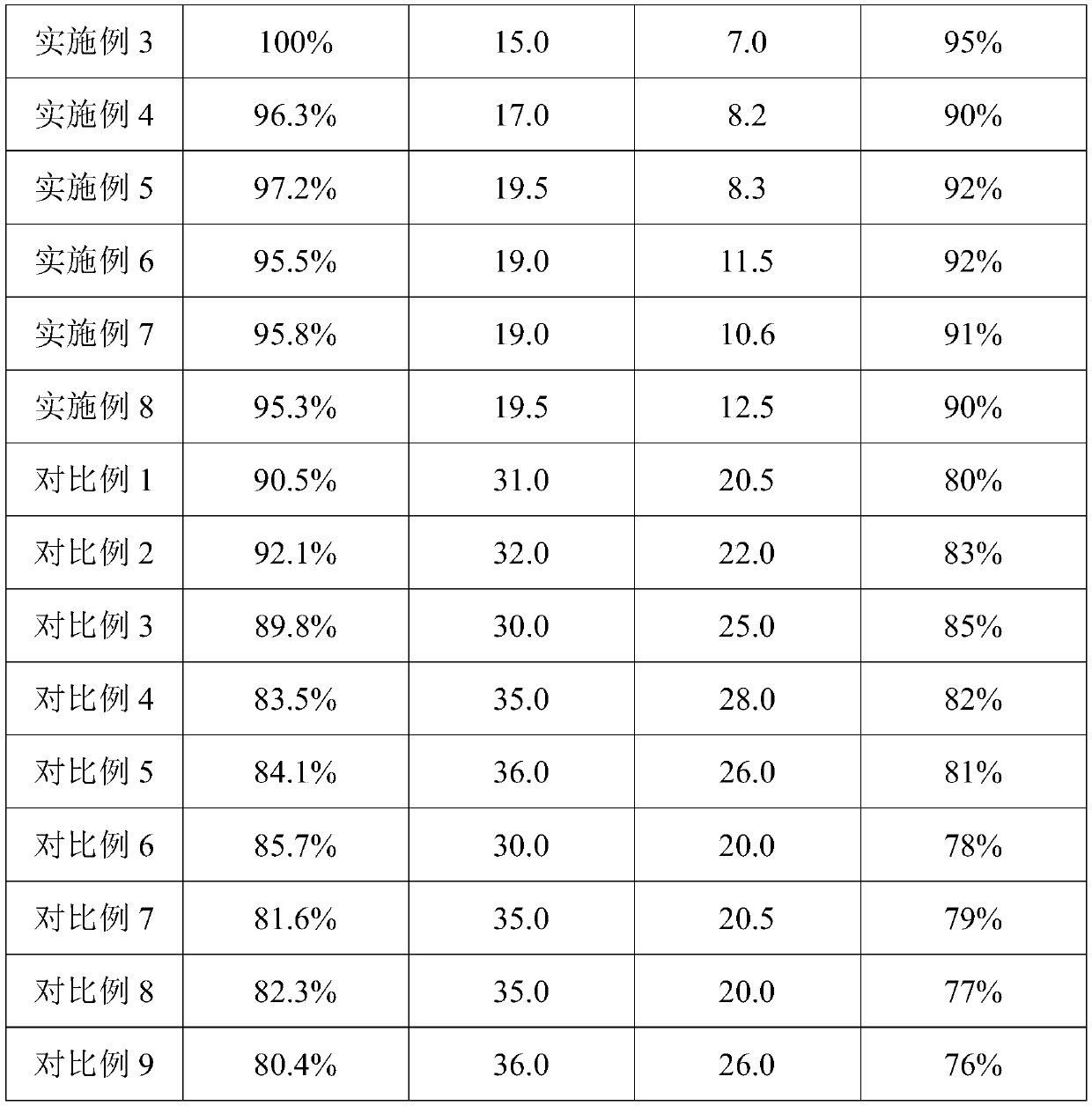

Examples

Embodiment 1

[0047] This embodiment provides a rust remover, which includes: 20% phosphoric acid, 5% hypophosphorous acid, 0.4% sodium fluoride, 1% sodium nitrate, 0.8% OP-10, isomerized ten Alcohol polyoxyethylene ether 0.4% and nitric acid 0.6%, the balance is deionized water.

[0048] The preparation method of the rust remover is as follows: according to the formula, phosphoric acid, hypophosphorous acid, sodium fluoride, sodium nitrate, OP-10, isomeric decanol polyoxyethylene ether, nitric acid and water are mixed at 20°C at 400r / min The speed of rotation is mixed and stirred for 20min to prepare the rust remover.

Embodiment 2

[0050] This embodiment provides a rust remover, which includes: 25% phosphoric acid, 3% hypophosphorous acid, 0.6% sodium fluoride, 2% sodium nitrate, 1.0% OP-10, isomerized ten Alcohol polyoxyethylene ether 0.2% and nitric acid 0.4%, the balance is deionized water.

[0051] The preparation method of the rust remover is as follows: according to the formula, phosphoric acid, hypophosphorous acid, sodium fluoride, sodium nitrate, OP-10, isomeric decanol polyoxyethylene ether, nitric acid and water are mixed at 10°C at 600r / min The speed of rotation is mixed and stirred for 10 minutes to prepare the rust remover.

Embodiment 3

[0053] This embodiment provides a rust remover, which includes: 22% phosphoric acid, 4% hypophosphorous acid, 0.5% sodium fluoride, 1.5% sodium nitrate, 0.9% OP-10, isomerized ten Alcohol polyoxyethylene ether 0.3% and nitric acid 0.5%, the balance is deionized water.

[0054] The preparation method of the rust remover is as follows: according to the formula, phosphoric acid, hypophosphorous acid, sodium fluoride, sodium nitrate, OP-10, isomeric decanol polyoxyethylene ether, nitric acid and water are mixed at 30°C at 300r / min The rotating speed, mix and stir 30min, make described rust remover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com