Coke oven raw gas and waste gas waste heat recycling system

A waste heat recovery and waste gas technology, applied in the heating of coke ovens, coke ovens, waste heat treatment, etc., can solve the problems of high cost, waste heat sensible heat, and inability to recover heat energy of coke oven waste gas, etc., and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

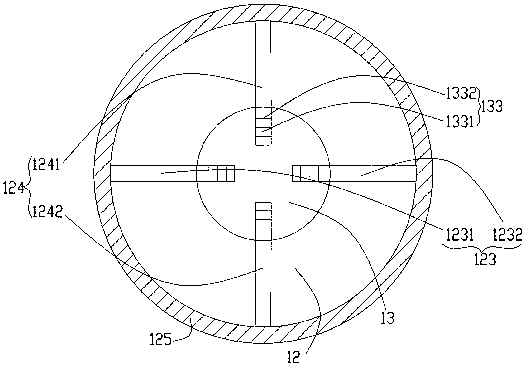

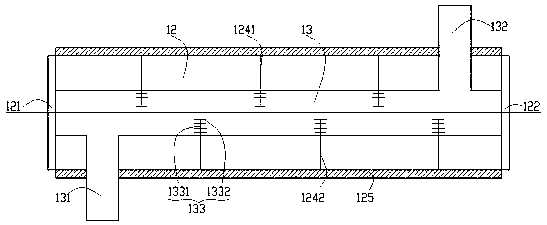

[0022] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings without paying creative work.

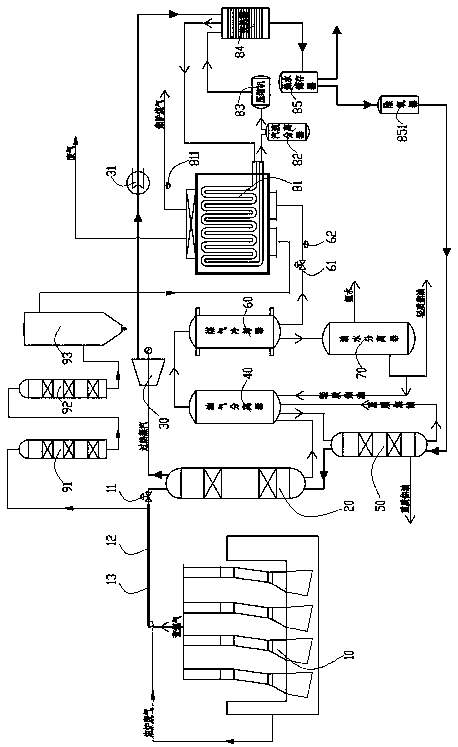

[0023] see Figure 1 to Figure 3, The present invention provides a coke oven raw gas and exhaust gas waste heat recovery and reuse system, including a coke oven 10, a high-temperature waste heat boiler 20, a steam turbine 30, an oil-gas separator 40, a low-temperature waste heat boiler 50, a gas cooler 60, and an oil-water separator 70. Low-temperature waste heat recovery device, the raw gas outlet end of the coke oven 10 is connected to the first inlet of the high-temperature waste heat boiler 20, so as to transport a large amount of raw gas at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com