Method for modifying silicon-carbon composite negative electrode by asphalt modification process derivative

A technology of silicon-carbon composite and asphalt modification, applied in battery electrodes, nanotechnology for materials and surface science, electrical components, etc., can solve problems such as unsuitable for industrial production, broken silicon-based material structure, pulverization, etc. , to achieve the effect of improving Coulombic efficiency and cycle retention rate, smooth molecular decomposition and polymerization reaction, and reducing volatile gas escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] A method for modifying silicon-carbon composite negative electrodes by asphalt modification process derivatives, the method is realized through the following steps:

[0029] Step 1. In step 1, the asphalt softening point is obtained by mixing any one or more of 80-280° C.; the non-polar solvent is an alkane (the molecular formula is C n h 2n+2 ), naphthenes (molecular formula is C n h 2n ), cycloalkene (molecular formula is C n h 2n-2 ), cycloalkynes (molecular formula is C n h 2n-4 )(5≤n≤16), monocyclic aromatic hydrocarbons (benzene, toluene, ethylbenzene, o-xylene, m-xylene, p-xylene, propylbenzene, isopropylbenzene, para-trimethylbenzene, mesitylene, mesitylene Any one or more non-polar mixed solvents among toluene, styrene, phenylacetylene) and aromatic compounds containing benzene rings (number of benzene rings≤2). The ratio of bitumen to non-polar solvent is 1:40-1:4.

[0030] Step 2, heating and stirring the asphalt mixed solution to accelerate the full ...

Embodiment 1

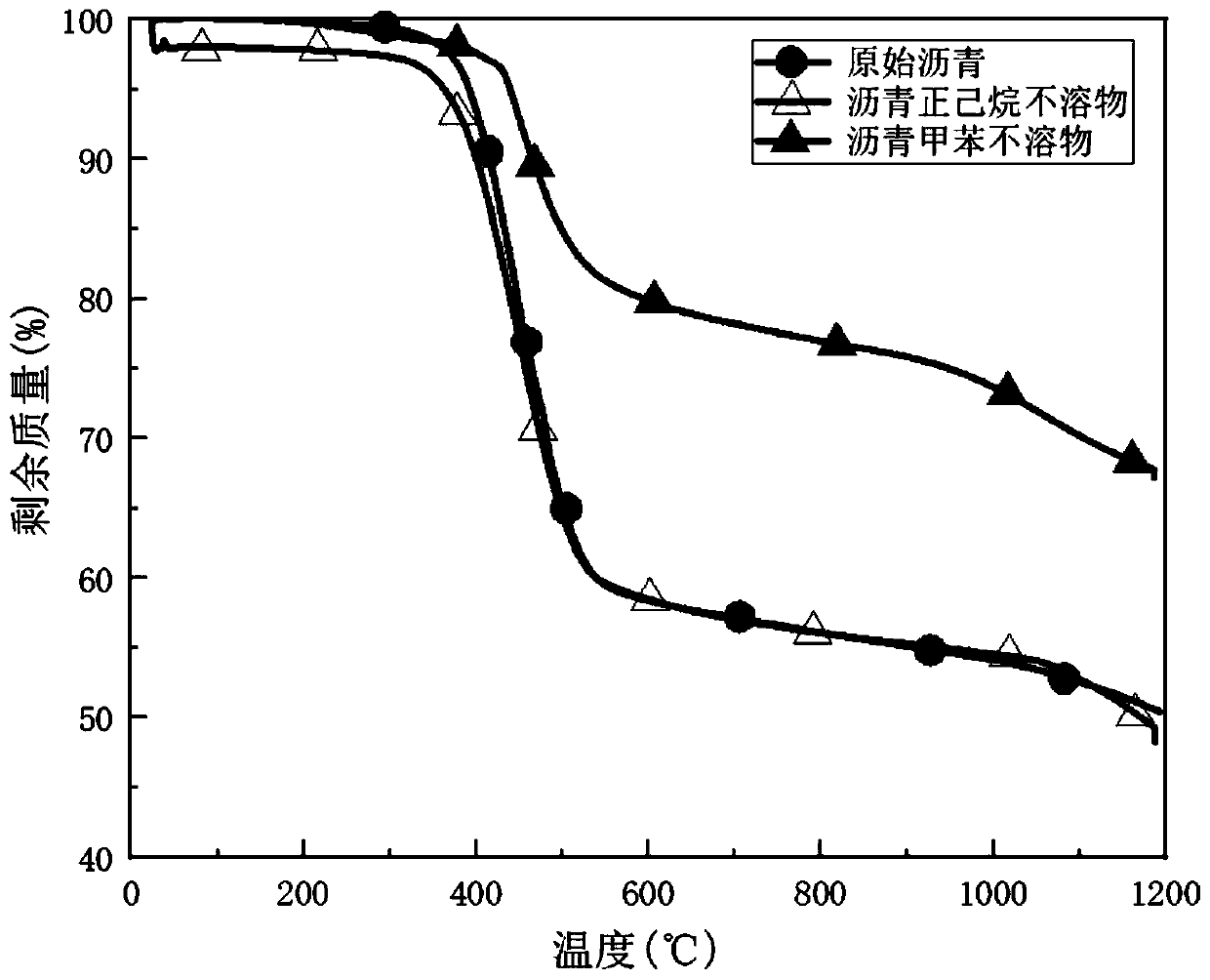

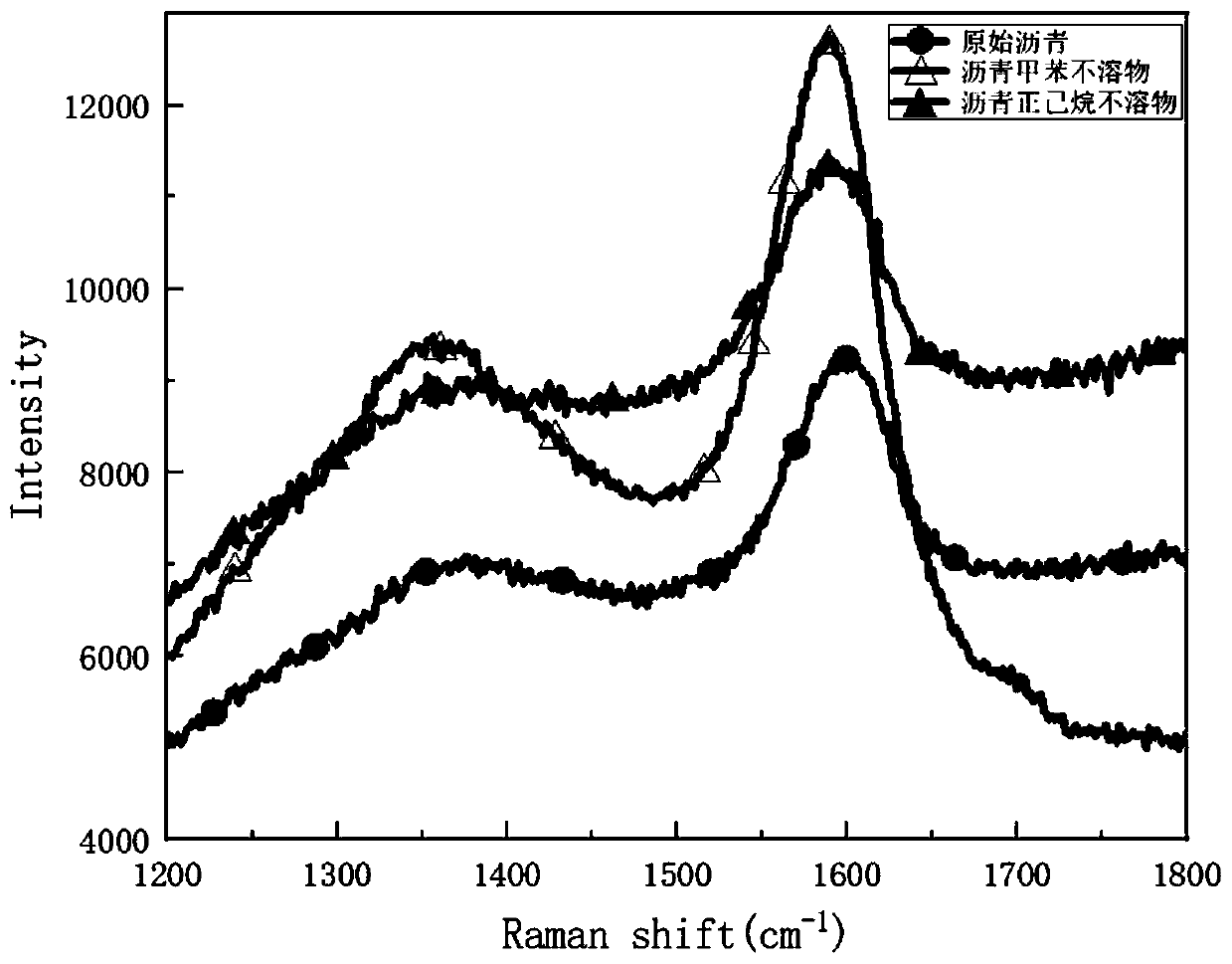

[0035] Step 1. Weigh 1 part of pitch with a softening point of 250°C and a particle size D50 of 1.8 μm, and uniformly disperse it in 40 parts of toluene solvent to obtain a pitch and toluene dispersion solution.

[0036] Step 2. Heat the asphalt and toluene dispersion to 50°C and stir at a speed of 300r / min for 3 hours to fully dissolve the asphalt in the toluene solvent to obtain toluene and asphalt dispersion;

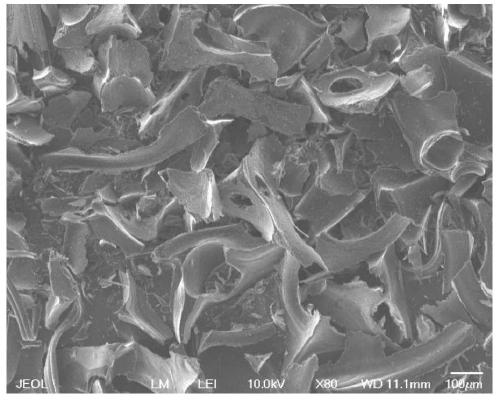

[0037] Step 3. Suction filter the toluene and asphalt dispersion solution, and wash the undissolved asphalt with the toluene solution for several times until the filtrate no longer changes color, and obtain asphalt toluene insoluble matter;

[0038] Step 4, put 1 part of asphalt toluene insoluble matter, 1 part of D50 of 150nm nano-silicon, and 8 parts of D50 of 3 μm graphite into a ball mill for ball milling; the ball mill speed is 300rpm, the ball milling time is 3h, and the ball-to-material ratio is 10:1; Obtain the precursor of the pitch-coated silicon-carbon com...

Embodiment 2

[0051] Step 1. Weigh 1 part of asphalt with a softening point of 250°C and a particle size D50 of 1.8 μm, and uniformly disperse it in 40 parts of n-hexane solvent to obtain a mixed solution of asphalt and n-hexane.

[0052] Step 2. Heat the mixed solution of asphalt and n-hexane to 50°C, and stir at a speed of 300r / min for 3 hours to accelerate the dissolution of asphalt in n-hexane;

[0053] Step 3. Suction filter the asphalt dispersion solution, and wash the undissolved asphalt with n-hexane several times until the filtrate no longer changes color, and obtain the asphalt n-hexane insoluble matter;

[0054] Step 4. Put 1 part of asphalt n-hexane insoluble matter, 1 part of D50 of 150nm nano-silicon, and 8 parts of D50 of 3 μm graphite into a ball mill for ball milling; the speed of the ball mill is 300rpm, the ball milling time is 3h, and the ball-to-material ratio is 10:1 ; Obtain the precursor of pitch n-hexane insoluble matter coated silicon-carbon composite negative elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com