Steady-state polycarboxylate superplasticizer with core-shell structure and preparation method of steady-state polycarboxylate superplasticizer

A technology of superplasticizer and polycarboxylic acid, applied in the field of concrete admixtures, can solve the problems of inability to achieve, waste of slump retention performance, low water reduction performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

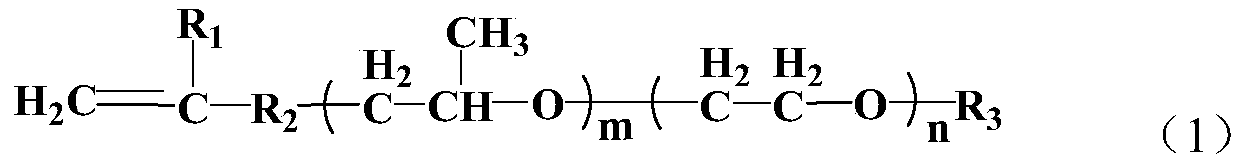

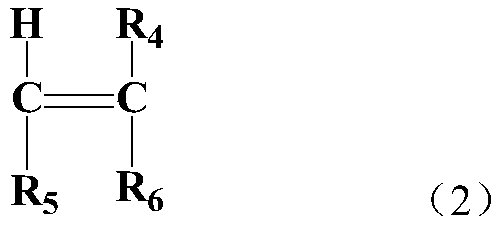

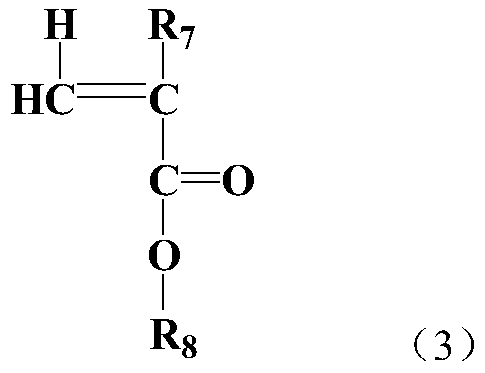

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In a reactor equipped with a thermometer and a stirrer, add 1300g of A-1 (1mol) and 400g of water, heat up to 60°C while stirring to dissolve and stir for 1 hour to prepare pre-emulsion 1. Add 72gB-1 (1mol), 172.2gC-1 (2mol), 12.2gD-1 (0.027mol) and 300g water into the batching kettle, and stir for 1 hour to prepare pre-emulsion 2. After adding 4.56g of 30% hydrogen peroxide to the pre-emulsion 1, the pre-emulsion 2 was continuously added to the reactor with a peristaltic pump, and the feeding time was 2 hours. At the same time, 200 g of an aqueous solution dissolved with 0.71 g of L-ascorbic acid and 6.29 g of mercaptoethanol was continuously added to the reactor with a peristaltic pump, and the feeding time was 2 hours.

[0077] Add 950g of E-1 (1mol) to the reactor at one time, and when the temperature stabilizes to 60°C, start to drop the solution containing 216g of B-1 (3mol), 348g of F-1 (3mol) and 500g of water, and the feeding time is 2 hours . At the same tim...

Embodiment 2

[0079]In a reactor equipped with a thermometer and a stirrer, add 3200g of A-2 (1mol) and 2000g of water, and control the temperature to 10°C while stirring to dissolve and stir for 1 hour to prepare pre-emulsion 1. Add 215g of B-2 (2.5mol), 550.5g of C-2 (5.5mol), 61.2g of D-3 (0.024mol) and 800g of water into the batching kettle, and stir for 1 hour to prepare pre-emulsion 2. After adding 35 g of ammonium persulfate to the pre-emulsion 1, the pre-emulsion 2 was continuously added to the reactor with a peristaltic pump, and the feeding time was 3 hours. At the same time, 900 g of an aqueous solution dissolved with 2.66 g of sodium formaldehyde sulfoxylate and 41.5 g of mercaptopropanol was continuously added to the reactor with a peristaltic pump, and the feeding time was 3 hours.

[0080] Add 2500g of E-2 (1mol) to the reactor at one time, and when the temperature stabilizes to 10°C, start to drop the solution containing 258g of B-2 (3mol), 260g of F-2 (2mol) and 2000g of wa...

Embodiment 3

[0082] In a reactor equipped with a thermometer and a stirrer, add 5500g of A-3 (1mol) and 6000g of water, heat up to 45°C while stirring to dissolve and stir for 1 hour to prepare pre-emulsion 1. Add 464g of B-3 (4mol), 912.8g of C-3 (8mol), 165.2g of D-5 (0.0038mol) and 2400g of water into the batching kettle, and stir for 1 hour to prepare pre-emulsion 2. After adding 102.4 g of sodium persulfate to the pre-emulsion 1, the pre-emulsion 2 was continuously added to the reactor with a peristaltic pump, and the feeding time was 4 hours. At the same time, 2000 g of an aqueous solution dissolved with 10.8 g of sodium bisulfite and 35.9 g of mercaptopropanol was continuously added to the reactor with a peristaltic pump, and the feeding time was 4 hours.

[0083] Add 4050g of E-3 (1mol) to the reactor at one time, and start to drop the solution containing 464g of B-3 (4mol), 504g of F-3 (3.5mol) and 5200g of water when the temperature stabilizes to 45°C. The feeding time is 4 Hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com