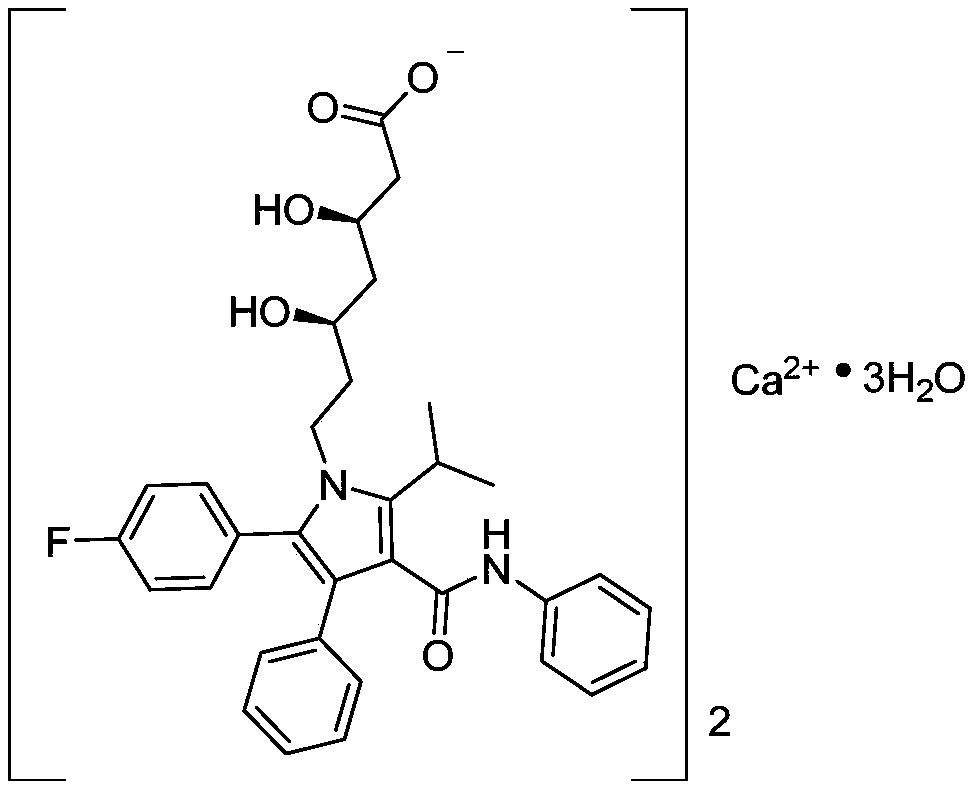

Method for producing atorvastatin calcium by using micro-reaction device

A technology of atorvastatin calcium and micro-reaction devices, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve difficult problems such as recrystallization and separation, Achieve the effects of easy heat and mass transfer, high selectivity, and small reaction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

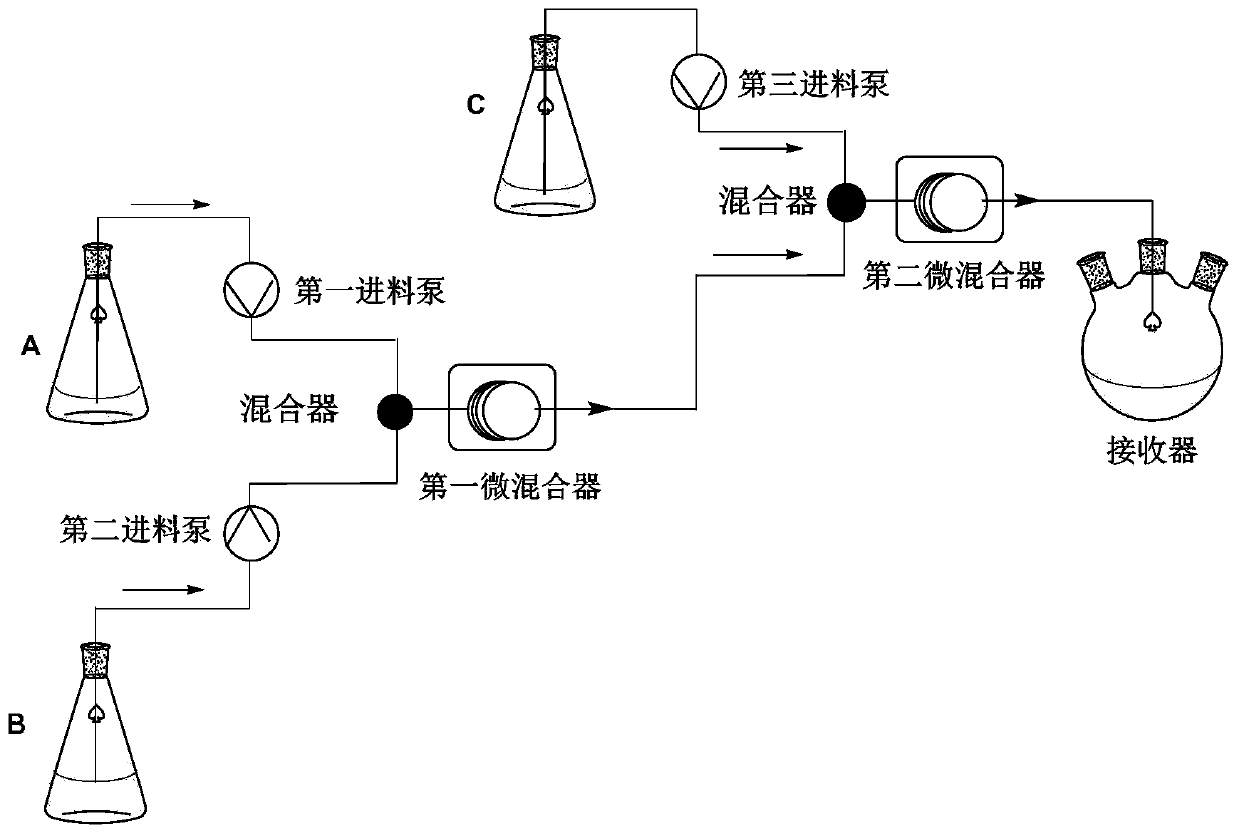

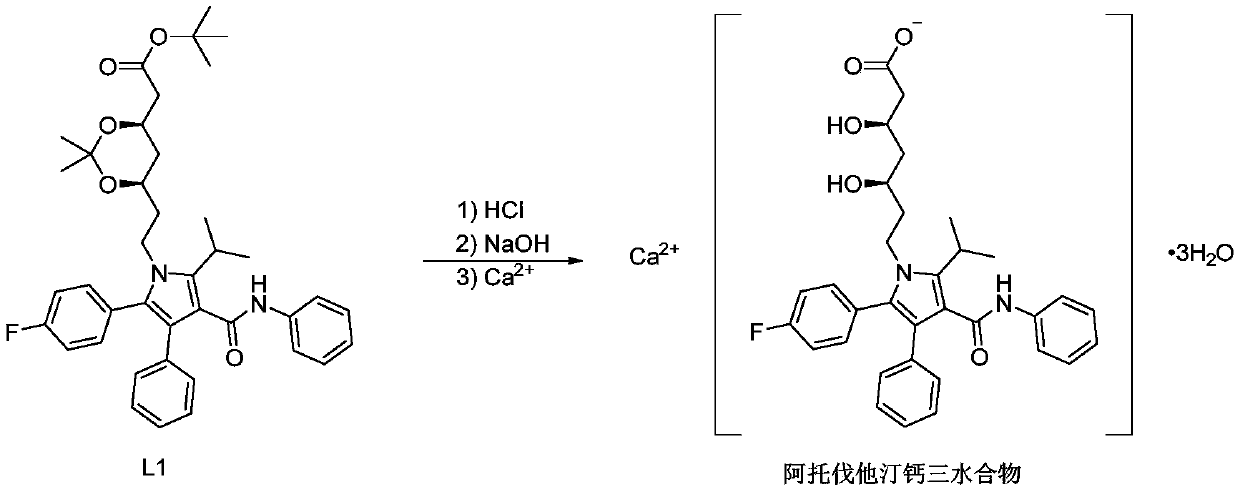

Embodiment 1

[0041] Weigh 20mL of 0.5mol / L hydrochloric acid solution, stir at room temperature to mix evenly to make homogeneous solvent A. Weigh 1.0 g of atorvastatin calcium intermediate L1, dissolve in 20 ml of aqueous methanol (methanol: water = 7: 3), stir at room temperature to mix evenly to form a homogeneous solution B. Weigh 0.8g of sodium hydroxide and dissolve it in 20mL of water, stir at room temperature to make it evenly mixed to make a homogeneous solution C. The homogeneous solution A and the homogeneous solution B are pumped into the Y-shaped mixer at a flow rate of 0.868mL / min respectively, and after mixing, they are passed into the first microreactor with a coil inner diameter of 1mm. The volume of the reactor is 5mL. The temperature is controlled at 40°C, and the reaction residence time is 20min; at the same time, the homogeneous solution C is pumped into the T-type mixer at a flow rate of 0.12mL / min, and after mixing, it is passed into the second microreactor, and the ...

Embodiment 2

[0043] Weigh 20mL of 0.5mol / L hydrochloric acid solution, stir at room temperature to mix evenly to make homogeneous solvent A. Weigh 1.0 g of atorvastatin calcium intermediate L1, dissolve in 20 ml of aqueous methanol (methanol: water = 7: 3), stir at room temperature to mix evenly to form a homogeneous solution B. Weigh 0.8g of sodium hydroxide and dissolve it in 20mL of water, stir at room temperature to make it evenly mixed to make a homogeneous solution C. The homogeneous solution A and the homogeneous solution B are pumped into the Y-type mixer at a flow rate of 0.428mL / min respectively, and after mixing, they are passed into the first microreactor with a coil inner diameter of 1mm. The volume of the reactor is 10mL. The temperature is controlled at 50°C, and the reaction residence time is 20min; at the same time, the homogeneous solution C is pumped into the T-type mixer at a flow rate of 0.12mL / min, and after mixing, it is passed into the second microreactor, and the v...

Embodiment 3

[0045] Weigh 20mL of 0.5mol / L hydrochloric acid solution, stir at room temperature to mix evenly to make homogeneous solvent A. Weigh 1.0 g of atorvastatin calcium intermediate L1, dissolve in 20 ml of aqueous methanol (methanol: water = 7: 3), stir at room temperature to mix evenly to form a homogeneous solution B. Weigh 0.8g of sodium hydroxide and dissolve it in 20mL of water, stir at room temperature to make it evenly mixed to make a homogeneous solution C. The homogeneous solution A and the homogeneous solution B are pumped into the Y-shaped mixer at a flow rate of 0.428mL / min respectively, and after mixing, they are passed into the first microreactor with a coil inner diameter of 1mm. The volume of the reactor is 15mL. The temperature is controlled at 60°C, and the reaction residence time is 20min; at the same time, the homogeneous solution C is pumped into the T-type mixer at a flow rate of 0.12mL / min, and after mixing, it is passed into the second microreactor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com