Industrial production method of 4-amino-5-imidazolecarboxamide

A technology of imidazole carboxamide and production method is applied in the field of industrialized production of 4-amino-5-imidazole carboxamide, and can solve the problem that 4-amino-5-imidazole carboxamide cannot meet industrialized production, cannot generate economic benefits, and has no large-scale production. Scale supply and other issues, to achieve the effect of low price, stable quality and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

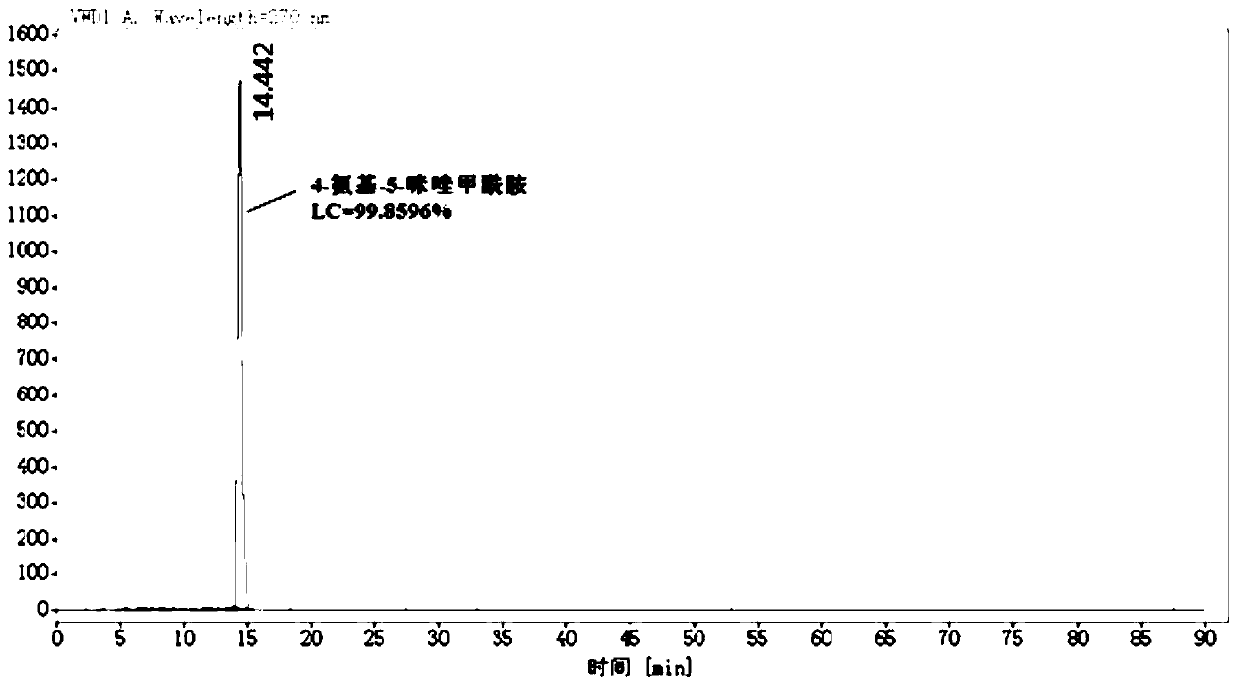

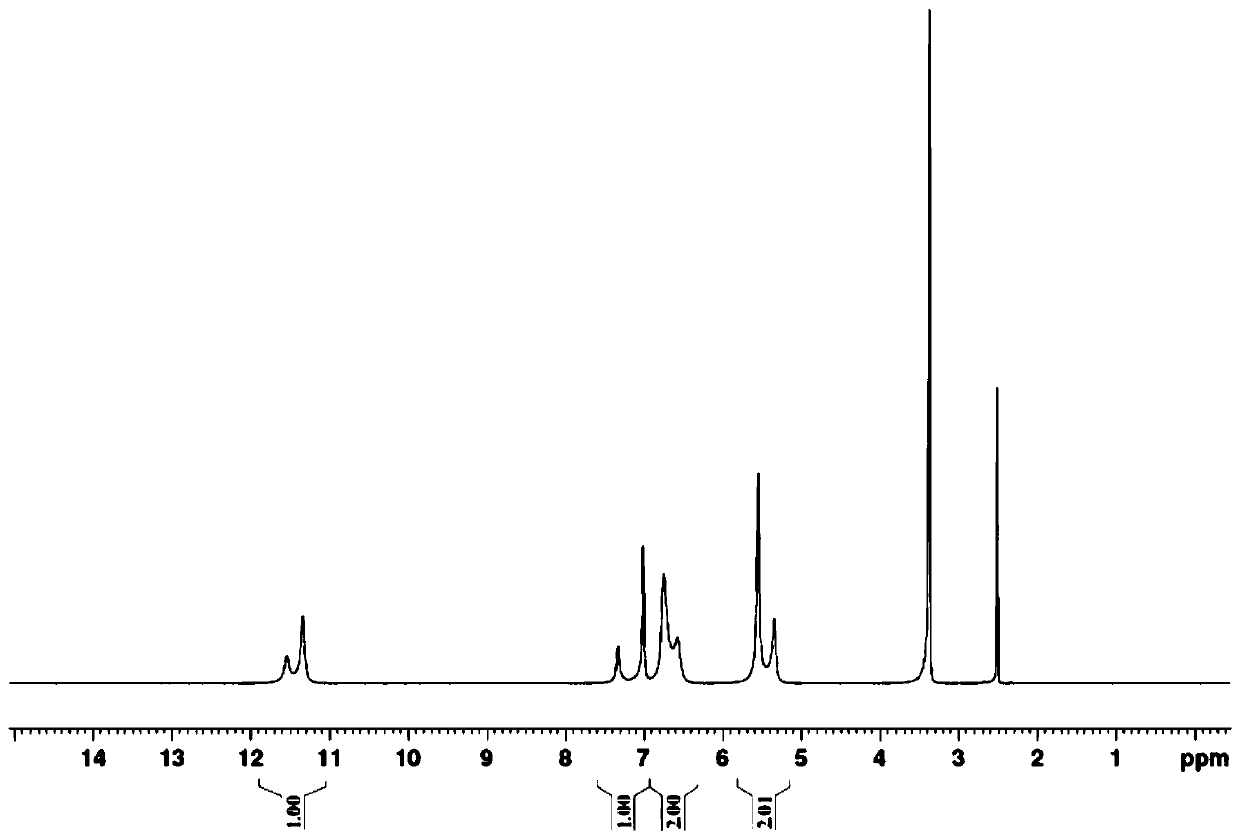

Examples

Embodiment 1

[0041] A kind of industrialized production method of 4-amino-5-imidazole carboxamide, specifically comprises the following steps:

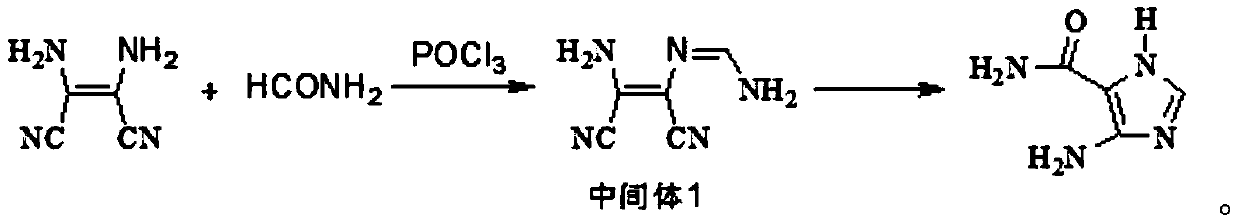

[0042] Step 1, synthesis of intermediate 1:

[0043] Under the protection of argon, add THF 1620mL, diaminomaleonitrile 324g, formamide 162g (1.2eq.) to a 5L three-necked flask equipped with a thermometer, dropping funnel and mechanical stirring, and cool down to 5°C in a cryogenic bath , began to add 550.8g (1.2eq.) of phosphorus oxychloride dropwise, and kept warm at 5°C for 2 hours after dropping, and began to take samples every 1 hour. When diaminomaleonitrile LC<0.3%, stop the reaction.

[0044] Post-treatment: Control the temperature at 20°C, add methanol 345.6g dropwise to the reaction solution, after the dropwise addition, control the temperature at 20°C for 2 hours, then slowly pour the system into 4.2L of water to quench, after quenching, keep warm at 20°C and stir for 20min , add 795g of sodium carbonate powder in batches until the pH of...

Embodiment 2

[0050] A kind of industrialized production method of 4-amino-5-imidazole carboxamide, comprises the following steps:

[0051] Step 1, synthesis of intermediate 1:

[0052] Under the protection of argon, add THF 1458mL, diaminomaleonitrile 162g, formamide 101.3g (1.5eq.) successively to a 5L three-neck flask equipped with a thermometer, a dropping funnel and a mechanical stirrer, and the low temperature bath is cooled to 0 ℃, start dropwise adding 344.7g (1.5eq.) of phosphorus oxychloride, keep warm at 35℃ for 2h after dropping, start sampling every 1h, stop the reaction when LC<0.3% of diaminomaleonitrile.

[0053] Post-treatment: Control the temperature at 30°C, add methanol 216g dropwise to the reaction liquid, after the dropwise addition is completed, control the temperature at 30°C for 2 hours, then slowly pour the system into 2.6L of water to quench, after quenching, keep warm at 30°C and stir for 20min, Add 487g of sodium carbonate powder in batches until the system pH=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com