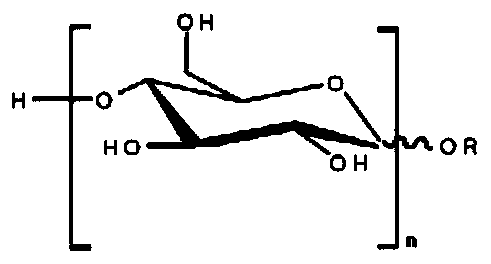

Synthesis process for surfactant, namely hexylglucoside

A technology of surfactant and synthesis process, which is applied in fermentation and other directions, can solve the problems of strict reaction conditions, excessive industrial waste, and easy coking, etc., and achieve the effect of no pollution in the process, easy access to raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

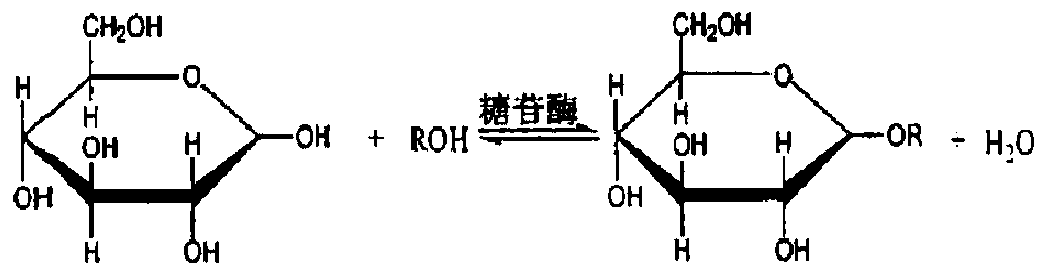

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of synthetic technique of surfactant hexyl glucoside

[0031] Specific steps are as follows:

[0032] Prepare a stoppered glass bottle, weigh 0.1000g glucose, add 0.8mL phosphate buffer (pH=6.0), 1.8mL n-hexanol, 80μL β-glucosidase enzyme solution (20mg / mL stock solution), mix well, put In a constant temperature oscillator at 50°C, the rotation speed was 180r / min, and the reaction was carried out for 36 hours.

[0033] Experimental results: the conversion rate of glucose is 30.12%.

experiment example

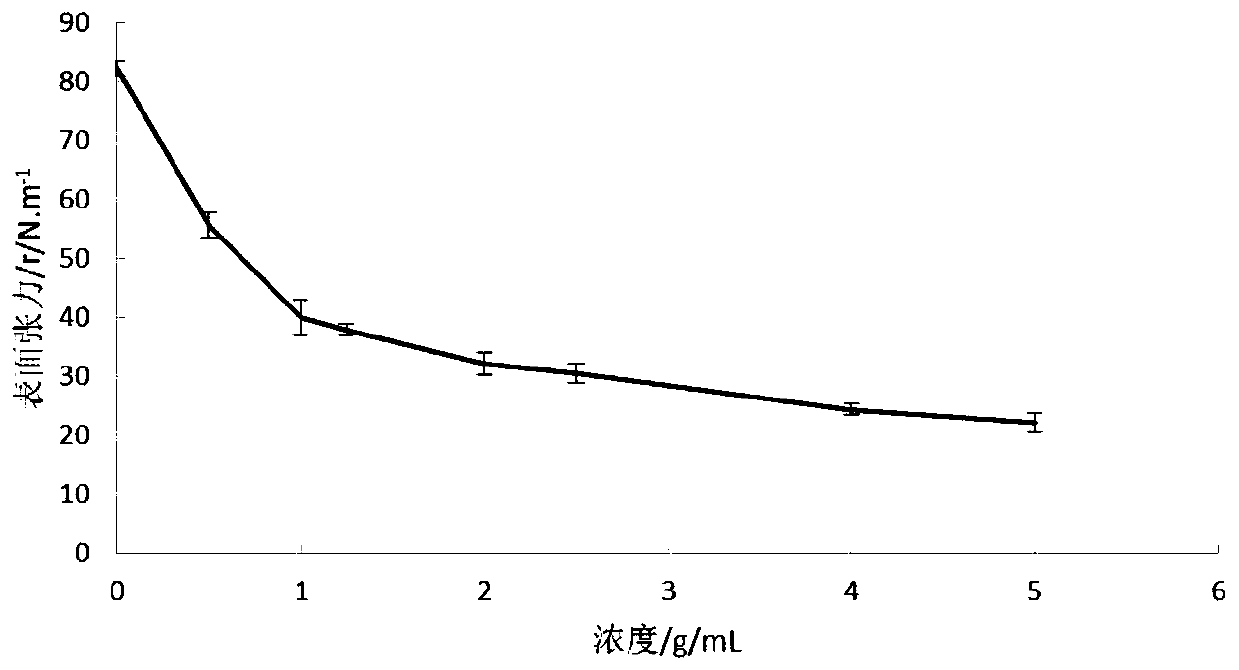

[0051] 1. Performance test

[0052] The performance test of Example 1 of the present invention was carried out. At the end of the reaction, the solution contained unreacted glucose and fatty alcohol, so the extraction method and vacuum distillation were used to separate and purify the product. After the reaction, the solution was poured into a separatory funnel, allowed to stand for 10 min, and then separated. The separated lower layer solution was extracted again, and the extractant was n-hexane and diethyl ether, which was repeated twice. Combine the extracted solution with the upper layer, remove hexanol and ether by vacuum distillation, and then carry out vacuum distillation on the remaining reaction solution at 160-180°C. After distillation, the solution is left to cool, and the product is light yellow. .

[0053] (1) Determination of surface tension and critical micelle concentration

[0054] The first is to prepare the instrument and check for leaks. Clean the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com