Silent compact movable methanol low-temperature liquid-phase reforming hydrogen=production system

A technology of reforming hydrogen production and low temperature liquid phase, applied in the field of hydrogen energy, can solve the problems of large volume of the reaction device, application limitation, difficult to popularize and apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

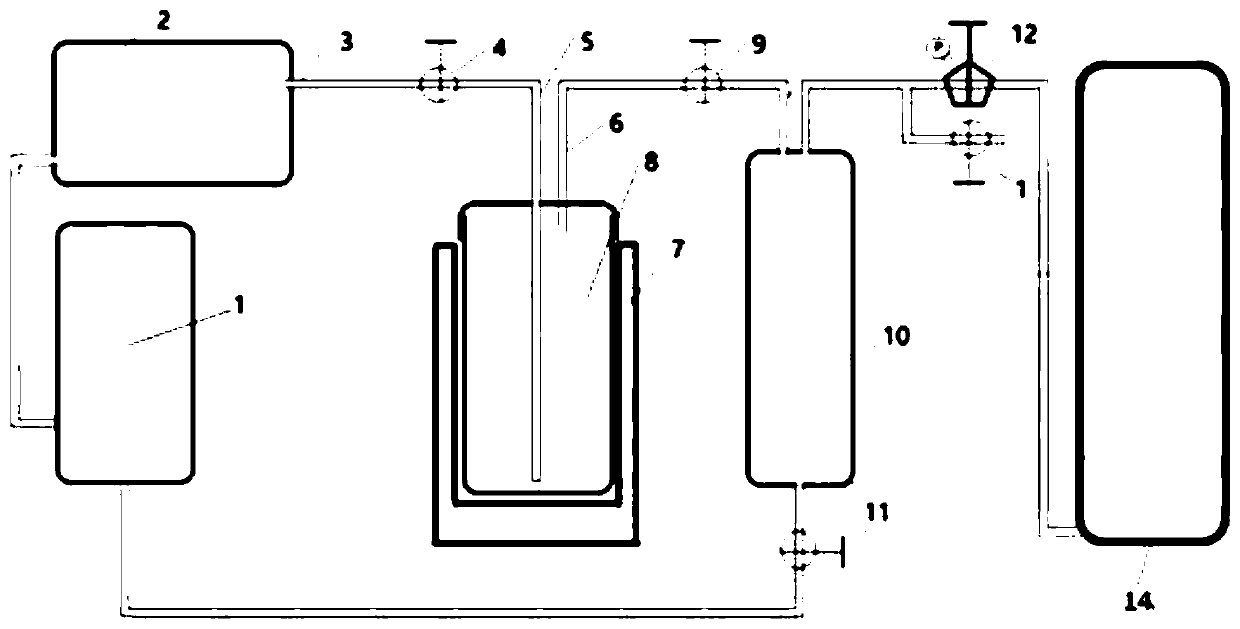

Method used

Image

Examples

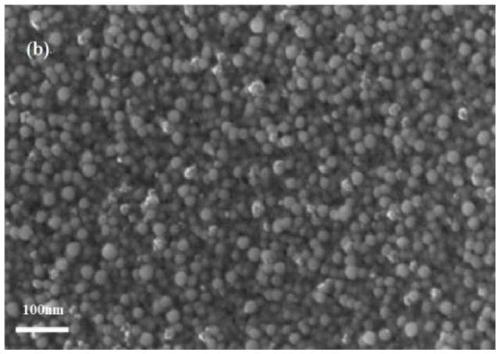

Embodiment 1

[0026] Using nickel nitrate as the nickel source and citric acid as the carbon source, a solution was prepared with methanol and mixed evenly, heated while stirring in an oil bath until dry, and then heat-treated at 600°C under nitrogen protection to obtain the Ni@C catalyst. Its SEM picture is as follows figure 2 As shown, the catalyst has a unique Ni 0 、Ni 3C Two kinds of crystal phase hybrid structure, the microscopic appearance is nanometer solid spherical particles with a particle size of 28nm, the particles have a core-shell structure, the outer layer is a citric acid pyrolysis carbon shell, and the inner layer is a metal Ni core. The obtained Ni@C catalyst particles were filled in the annular space of the hydrogen production reactor, and the hydrogen production reactor was heated to 150 °C by an electric heating mantle. Configure 40% methanol aqueous solution in the raw material tank, and use a high-pressure advection pump to continuously pump methanol aqueous soluti...

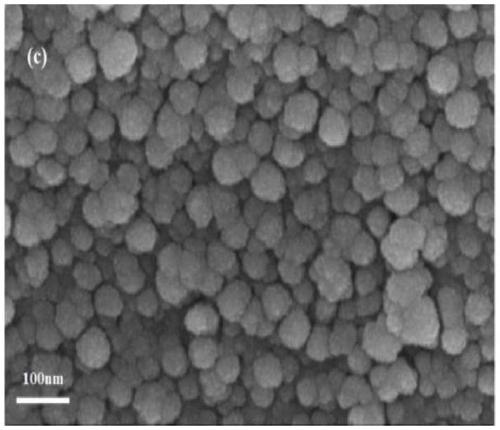

Embodiment 2

[0028] Use nickel nitrate and copper nitrate as nickel source and copper source, citric acid as carbon source, make a solution with methanol and mix evenly, heat while stirring in an oil bath until dry, and then heat treat at 700°C under nitrogen protection to obtain NiCu@C catalyst. Its SEM picture is as follows image 3 As shown, the catalyst has a unique Ni 0 、Ni 3 C. Ni 3 Cu three crystal phase hybrid structure, the microscopic appearance is 63nm porous microspheres with a particle size of 15nm nanometer solid spherical particles, in which the 15nm nanometer solid spherical particles are a core-shell structure, and the outer layer is a citric acid pyrolysis carbon shell , the inner layer is a metal NiCu alloy core. The obtained NiCu@C catalyst particles were filled in the annular space of the hydrogen production reactor, and the hydrogen production reactor was heated to 190 °C by an electric heating mantle. Configure methanol aqueous solution with a concentration of 6...

Embodiment 3

[0030] Use nickel nitrate and copper nitrate as nickel and copper sources, 2-methylimidazole as carbon and nitrogen source, make a solution with methanol and mix evenly, heat while stirring in an oil bath until dry, and then pass through 900°C under the protection of nitrogen. The NiCu@CN catalyst was obtained after heat treatment at ℃. Its SEM picture is as follows Figure 4 As shown, the catalyst has a unique Ni 0 、Ni 3 C and Ni 3 Cu has a hybrid structure of three crystal phases, the microscopic appearance is petal-shaped spherical particles with a particle size of 3.5 microns, and the petals are a lamellar structure with an average thickness of 21 nm. The obtained NiCu@CN catalyst particles were filled in the annular space of the hydrogen production reactor, and the hydrogen production reactor was heated to 250 °C by an electric heating mantle. Configure methanol aqueous solution with a concentration of 60% in the raw material tank, and use a high-pressure advection pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com