Modified aluminum polyphosphate antirust pigment prepared by high-temperature solid-phase one-step method and method thereof

An anti-rust pigment, high-temperature solid-phase technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as affecting product quality, poor anti-rust performance, and product impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

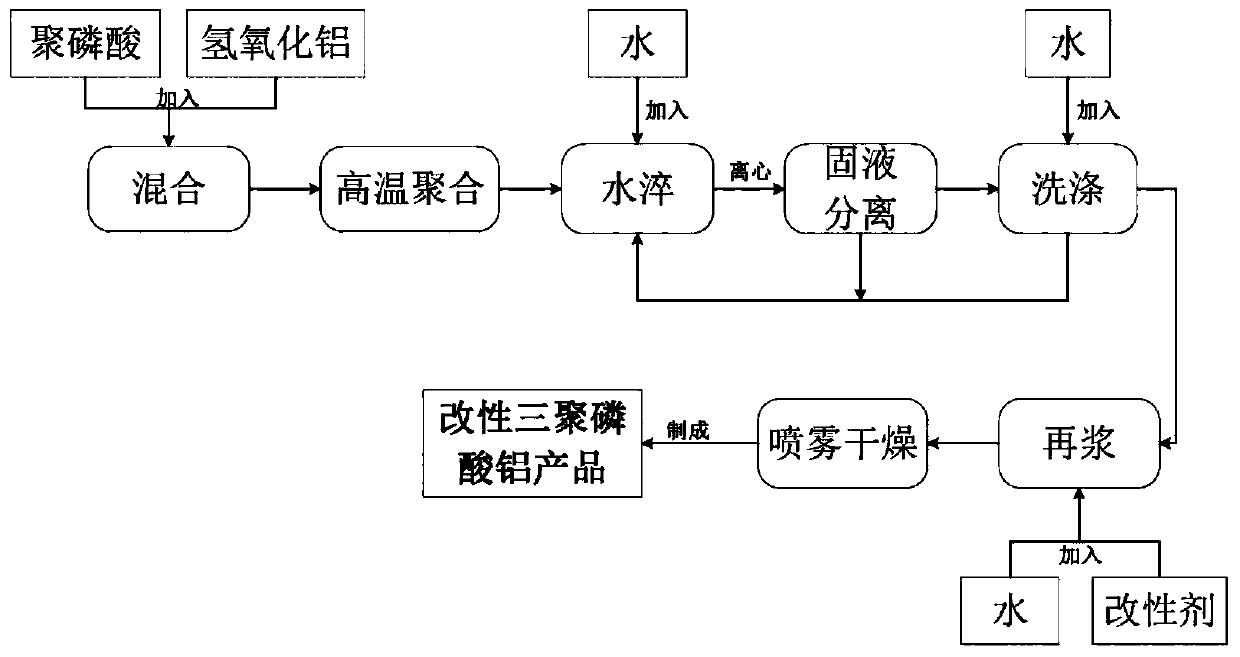

Image

Examples

Embodiment 1

[0050] (1) Polyphosphoric acid (P 2 o 5 The concentration is 73.4%) and aluminum hydroxide (Al 2 o 3 Calculation content is 96%) two kinds of raw materials are mixed in mixer (adopting high-temperature kneader in the embodiment) according to the consumption that mol ratio is 2.95, stir evenly;

[0051] (2) Polymerize the mixed material at a high temperature of 302°C for 2.5 hours to obtain white aluminum tripolyphosphate solid powder;

[0052] (3) Add 1.2 times of process water of the aluminum tripolyphosphate product, and carry out water quenching to the white solid powder obtained by high-temperature polymerization;

[0053] (4) The slurry obtained by water quenching is sent to a three-legged centrifuge for filtration and separation, adding 1.2 times of aluminum tripolyphosphate washing water to wash to obtain a filter cake, and adding 0.8 times of aluminum tripolyphosphate process water to the resulting filter cake repulping, making slurry;

[0054] (5) Add 10% zinc ox...

Embodiment 2

[0060] (1) Polyphosphoric acid (P 2 o 5 The concentration is 75.6%) and aluminum hydroxide (Al 2 o 3 Content is 98%) two kinds of raw materials are mixed in the mixer according to the consumption that molar ratio is 3.05, stir evenly;

[0061] (2) Polymerize the mixed material at a high temperature of 295°C for 3.0 hours to obtain white aluminum tripolyphosphate solid powder;

[0062] (3) Add 1.5 times of process water of the aluminum tripolyphosphate product, and water quench the white solid powder obtained by high-temperature polymerization;

[0063] (4) The slurry obtained by water quenching is sent to a three-legged centrifuge for filtration and separation, and 1.0 times the washing water of the aluminum tripolyphosphate product is added for washing, and the obtained filter cake is repulped by adding 1.0 times the process water of the aluminum tripolyphosphate product , to prepare slurry;

[0064] (5) Add zinc oxide and silicon dioxide of 15% and 13% (accounted for th...

Embodiment 3

[0070] (1) Polyphosphoric acid (P 2 o 5 The concentration is 79.2%) and aluminum hydroxide (Al 2 o 3 Content is 97%) two kinds of raw materials are mixed in mixer, stir evenly according to the consumption that molar ratio is 3.00;

[0071] (2) Polymerize the mixed material at a high temperature of 302°C for 3.0 hours to obtain white aluminum tripolyphosphate solid powder;

[0072] (3) Add 1.5 times of process water of the aluminum tripolyphosphate product, and water quench the white solid powder obtained by high-temperature polymerization;

[0073] (4) The slurry obtained by water quenching is sent to a three-legged centrifuge for filtration and separation, and 1.0 times the washing water of the aluminum tripolyphosphate product is added for washing, and the obtained filter cake is repulped by adding 1.0 times the process water of the aluminum tripolyphosphate product , to prepare slurry;

[0074] (5) Add zinc oxide and strontium oxide of 10% and 5% (according to the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com