Negative active material and preparation method thereof

A technology of negative electrode active material and active material, applied in the field of negative electrode active material and its preparation, can solve the problems of water sensitivity, limiting the utilization and commercialization process of silicon negative electrode material, large volume effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

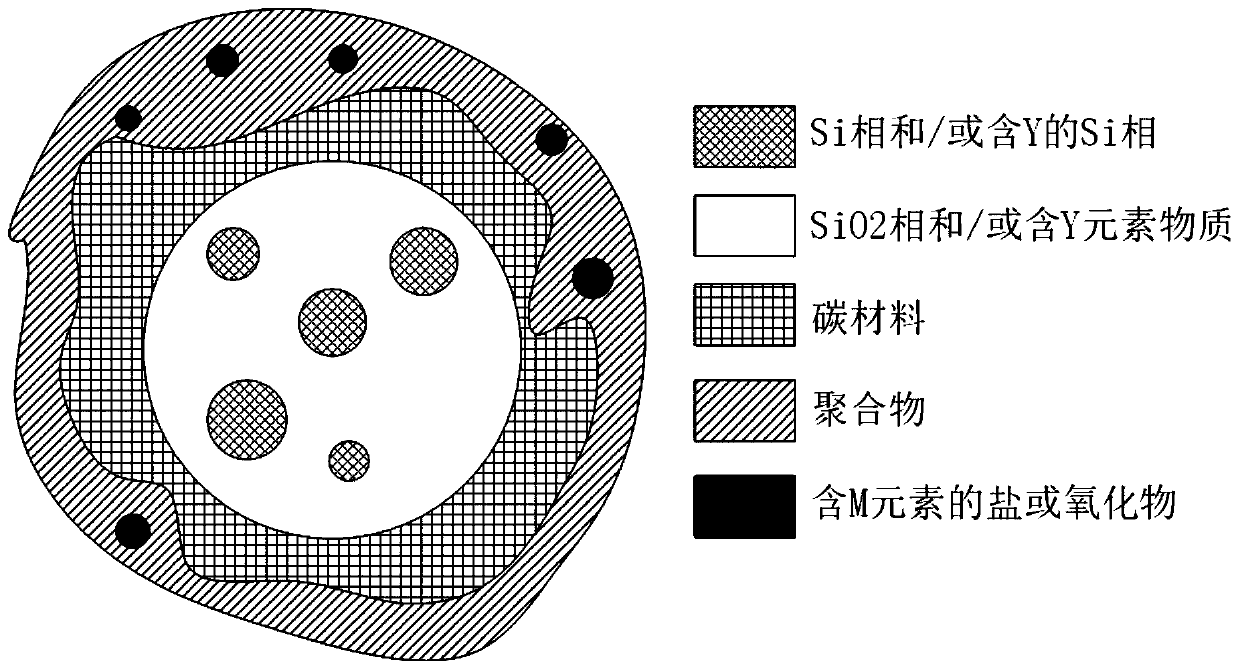

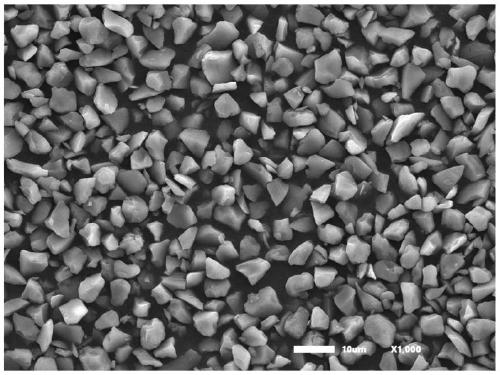

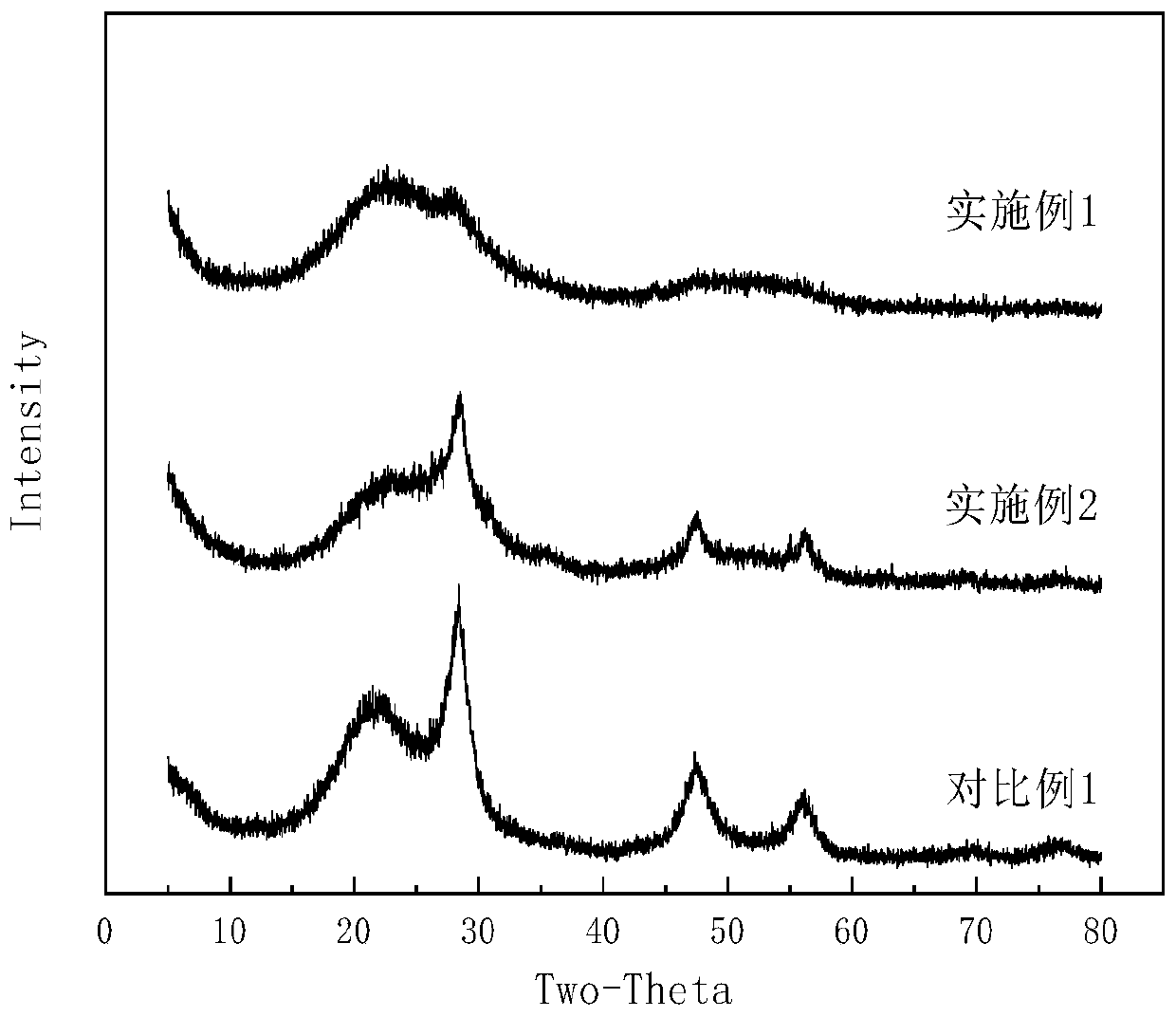

[0034] The negative electrode active material of this embodiment includes silicon-containing active material particles, polyacrylic acid coated on the silicon-containing active material particles, polyacrylic acid lithium layer, and Al dispersed in polyacrylic acid and polyacrylic acid lithium layer. 2 o 3 ; Wherein, silicon-containing active material particles include SiO x Particles, covered in SiO x Hard charcoal layer on the granules. The structure of the negative electrode active material is as figure 1 As shown in the scanning electron microscope image of figure 2 shown.

[0035] The preparation method of the negative electrode active material of the present embodiment comprises the following steps:

[0036] (1) Prepare the required raw materials, dissolve acrylic acid and lithium acrylate in a solvent to form a solution;

[0037] (2) Al 2 o 3 Dispersed in the solution to form a mixed solution;

[0038] (3) Spray and disperse the mixed solution on the surface o...

Embodiment 2

[0043] The negative active material of the present embodiment comprises silicon-containing active material particles, a polypropylene layer coated on the silicon-containing active material particles, and AlCl dispersed in the polypropylene layer; wherein the silicon-containing active material particles comprise SiO x particles well covered in SiOx Hard charcoal layer on the granules.

[0044] The preparation method of the negative electrode active material of the present embodiment comprises the following steps:

[0045] (1) Prepare the required raw materials, and dissolve acrylic acid in a solvent to form a solution;

[0046] (2) AlCl 3 Dispersed in the solution to form a mixed solution;

[0047] (3) Immerse the active material particles in the mixed solution, take out and dry to remove the solvent to obtain the negative electrode active material.

[0048] Wherein, the preparation method of active material particle comprises the following steps:

[0049] (1) Mix silicon p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com