Lithium battery composite diaphragm as well as preparation method and application thereof

A composite diaphragm and lithium battery technology, which is applied to lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of single function of the composite diaphragm, inability to have flame retardant function and conductivity at the same time, and achieve a simple preparation method. , Easy to enlarge the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

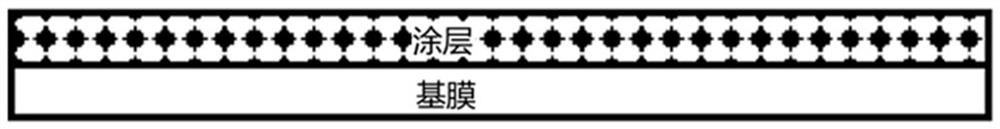

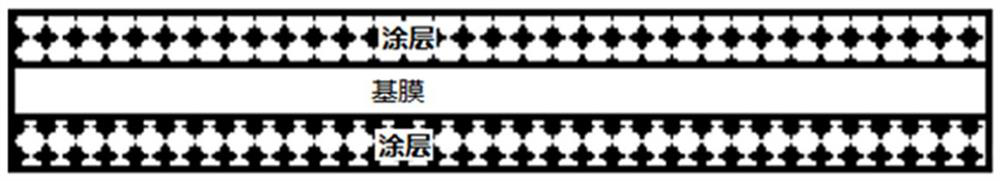

[0045] The present embodiment provides a preparation method of a lithium battery composite separator, comprising the following steps:

[0046] Step 1, put 100 parts by weight of Al 2 O 3 (average particle size 400 nm), 20 parts by weight of monomer M1, 0.2 parts by weight of initiator potassium persulfate, and 8 parts by weight of other additives were added to water, ball-milled uniformly, and configured into slurry N1 with a solid content mass fraction of 20%. Other additives include 0.5 parts by weight of dispersant polyethylene glycol, 3 parts by weight of thickener sodium carboxymethyl cellulose, 4 parts by weight of binder polymethacrylic acid and 0.5 parts by weight of wetting agent fluoro Alkyl methoxy alcohol ether.

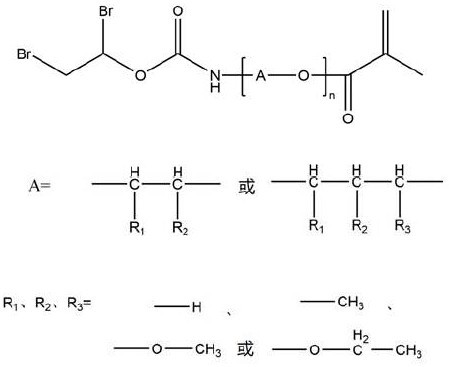

[0047] The structural formula of M1 is

[0048]

[0049] In the formula, A=-CH 2 CH 2 -, n=1.

[0050] An example of the preparation method of monomer M1 is:

[0051] Under argon atmosphere in the glove box, the raw material 0.01mol BrCH 2 CHBrCH...

Embodiment 2

[0056] The present embodiment provides a preparation method of a lithium battery composite separator, comprising the following steps:

[0057] Step 1. 100 parts by mass of SiO 2 (average particle size of 500 nm), 20 parts by mass of monomer M2, 0.2 parts by mass of initiator potassium persulfate, and 8 parts by mass of other additives were added to water, ball-milled uniformly, and prepared into a slurry N2 with a solid content mass fraction of 20%. Other additives include 0.5 parts by weight of dispersant polyethylene glycol, 3 parts by weight of thickener sodium carboxymethyl cellulose, 4 parts by weight of binder polymethacrylic acid and 0.5 parts by weight of wetting agent fluoro Alkyl methoxy alcohol ether.

[0058] The structural formula of M2 is

[0059]

[0060] In the formula, -CH(OCH 3 )CH 2 -, n=2.

[0061] The preparation method of monomer M2 is:

[0062] Under argon atmosphere in the glove box, the raw material 0.01molBrCH 2 CHBrCH 2 OH was dissolved in...

Embodiment 3

[0067] The present embodiment provides a preparation method of a lithium battery composite separator, comprising the following steps:

[0068] Step 1. 100 parts by mass of TiO 2 (average particle size of 300 nm), 10 parts by mass of monomer M3, 0.1 part by mass of initiator potassium persulfate, and 10.8 parts by mass of other additives were added to water, ball-milled uniformly, and configured into slurry N3 with a solid content of 30% by mass. Other additives include 0.8 parts by weight of dispersant polyethylene glycol, 2 parts by weight of thickener sodium carboxymethyl cellulose, 7 parts by weight of binder polymethacrylic acid and 1 part by weight of wetting agent fluorine Alkyl methoxy alcohol ether.

[0069] The structural formula of M3 is

[0070]

[0071] In the formula, -CH(OCH 3 )CH(OCH 3 )-, n=5.

[0072] The preparation method of monomer M3 is:

[0073] Under argon atmosphere in the glove box, the raw material 0.01mol BrCH 2 CHBrCH 2 OH was dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com