Bone black capable of efficiently oxidizing trivalent arsenic in water and application of bone black

A trivalent arsenic and water oxidation technology, applied in the direction of oxidation water/sewage treatment, water pollutants, other chemical processes, etc., can solve the problems of unsuitable application, increase of large dosage, long reaction time, etc., and achieve high-efficiency oxidation Trivalent arsenic, no secondary pollution, simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of bone char before acid treatment

[0033] Step 1): crush the bovine bone to particles with a particle size of less than 0.5 cm, then wash the bovine bone powder several times with deionized water, and dry it in an oven at 80° C. to obtain the bovine bone powder.

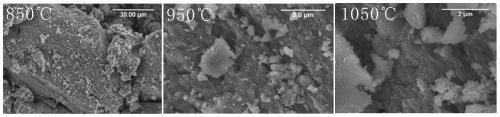

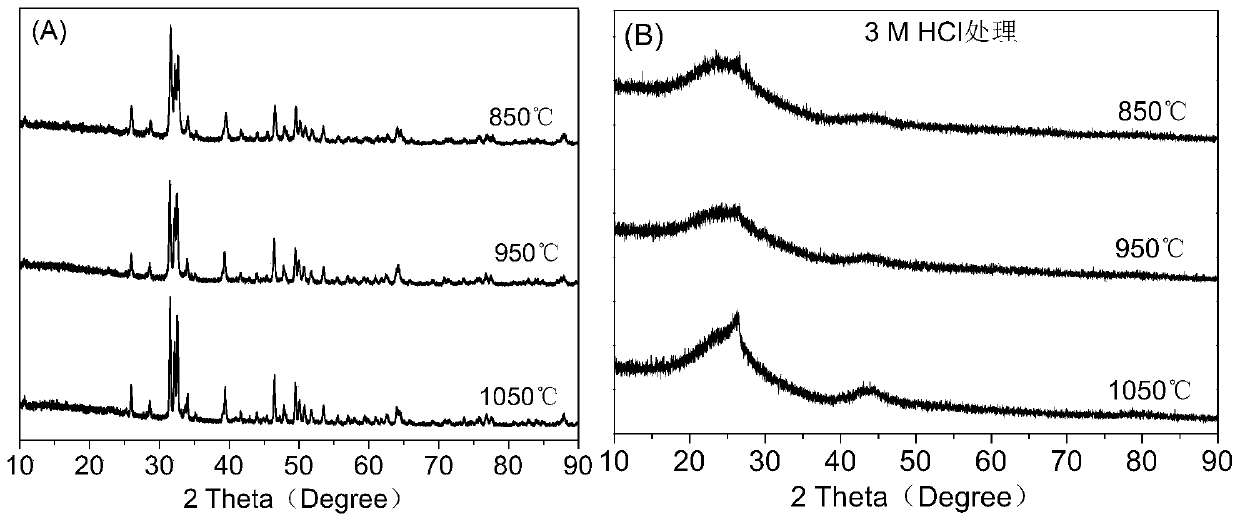

[0034] Step 2): Put 20g of bovine bone powder in a vacuum tube furnace, raise the temperature to 850°C in a nitrogen atmosphere, the heating rate is 15°C / min, stop heating after keeping for 60min, and take it out at room temperature to obtain the original bone char (i.e. Bone char before acid treatment), SEM sees figure 1 , see XRD image 3 A in

[0035] According to the above steps, the original bone chars carbonized at 950 °C and 1050 °C were prepared respectively, SEM see figure 1 , see XRD image 3 A in

[0036] 2. Bone charcoal preparation

[0037] Step 1): Soak the raw bone charcoal prepared above in 3mol / L hydrochloric acid, sonicate for 10 minutes, and oscillate (200rpm) for 30 m...

Embodiment 2

[0039] Example 2: Research on Oxidation of Trivalent Arsenic by Bone Char prepared at Different Pyrolysis Temperatures

[0040] Step 1): Prepare trivalent arsenic solutions with a concentration of 5 mg / L and 10 mg / L, and the solvent is ultrapure water.

[0041] Step 2): Bone charcoal, biochar and activated carbon materials prepared at different pyrolysis temperatures in Example 1 before and after acid treatment were used for trivalent arsenic oxidation experiments. The activated carbon was analytically pure and purchased from Guangzhou Chemical Reagent Factory. The preparation steps of biochar are as follows: the biomass raw material palm is crushed to particles with a particle size of less than 0.5 cm, placed in a vacuum tube furnace, and heated to the pyrolysis temperature under the protection of nitrogen (400 ° C and 500 ° C pyrolysis to prepare two groups of biochars, respectively). carbon), pyrolyzed for 2 hours; then soaked in 3mol / L hydrochloric acid, ultrasonicated fo...

Embodiment 3

[0046] Example 3: Research on the oxidation of trivalent arsenic by bone charcoal under different pH conditions

[0047] Step 1): Prepare a trivalent arsenic solution with a concentration of 5 mg / L, and the solvent is ultrapure water.

[0048] Step 2): According to Example 2, it can be known that the acid-treated bone char pyrolyzed at 950°C has the best oxidation effect on trivalent arsenic, so the acid-treated bone char material pyrolyzed at 950°C prepared in Example 1 was used for different Kinetic experiment of trivalent arsenic oxidation under the condition of pH value, using 0.1mg / L HCl and 0.1mg / L NaOH solution to adjust the initial pH value of the trivalent arsenic solution to 5.5, 7.5 and 8.5 respectively, and the dosage of bone char material is 0.1g / L, the reaction system is 20mL, placed in a 50mL centrifuge tube.

[0049] Step 3): Start timing after feeding, and take samples at specified time points. The sampling times are 0, 15, 30, 60, 120, 180, and 300 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com