Fly ash water purification method

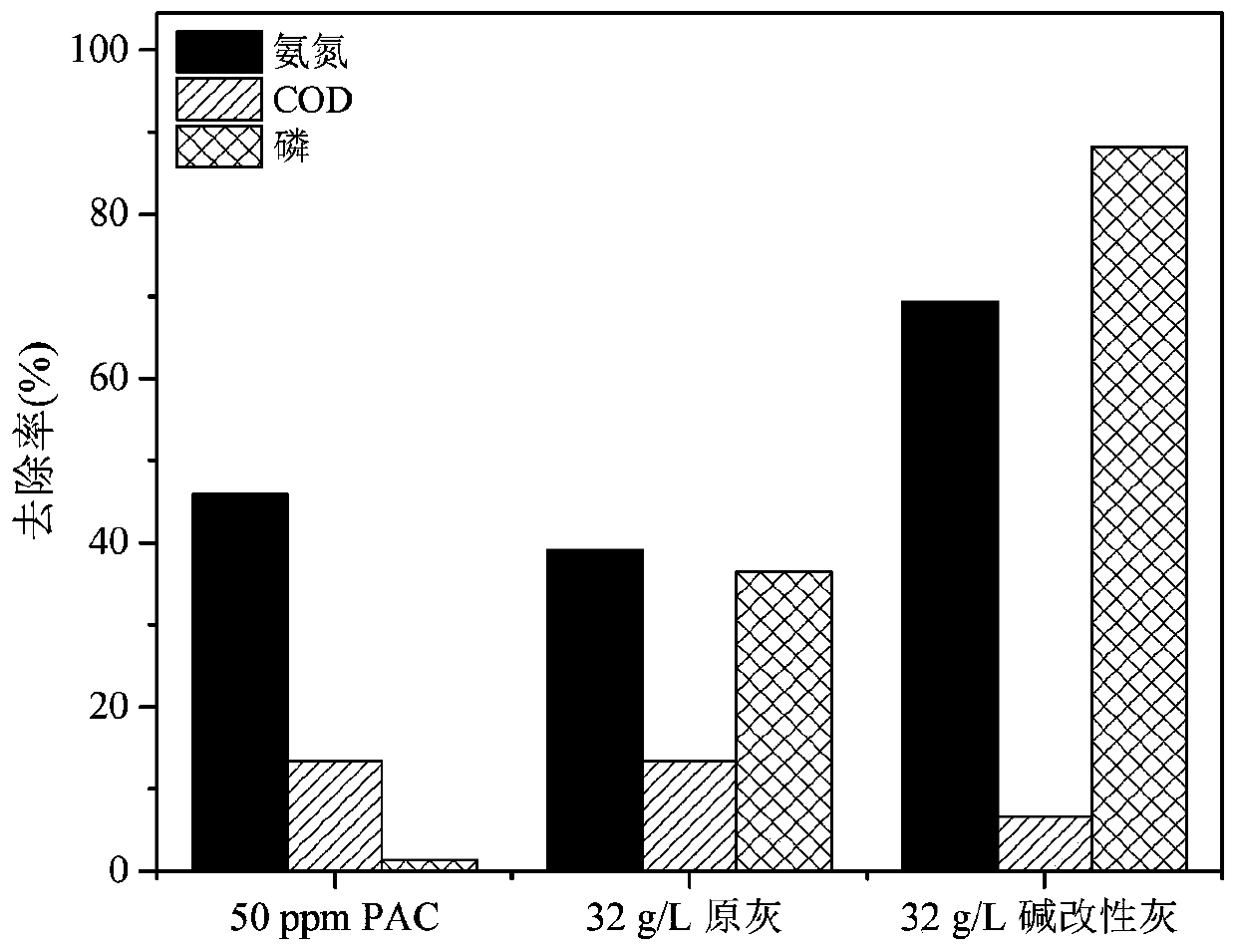

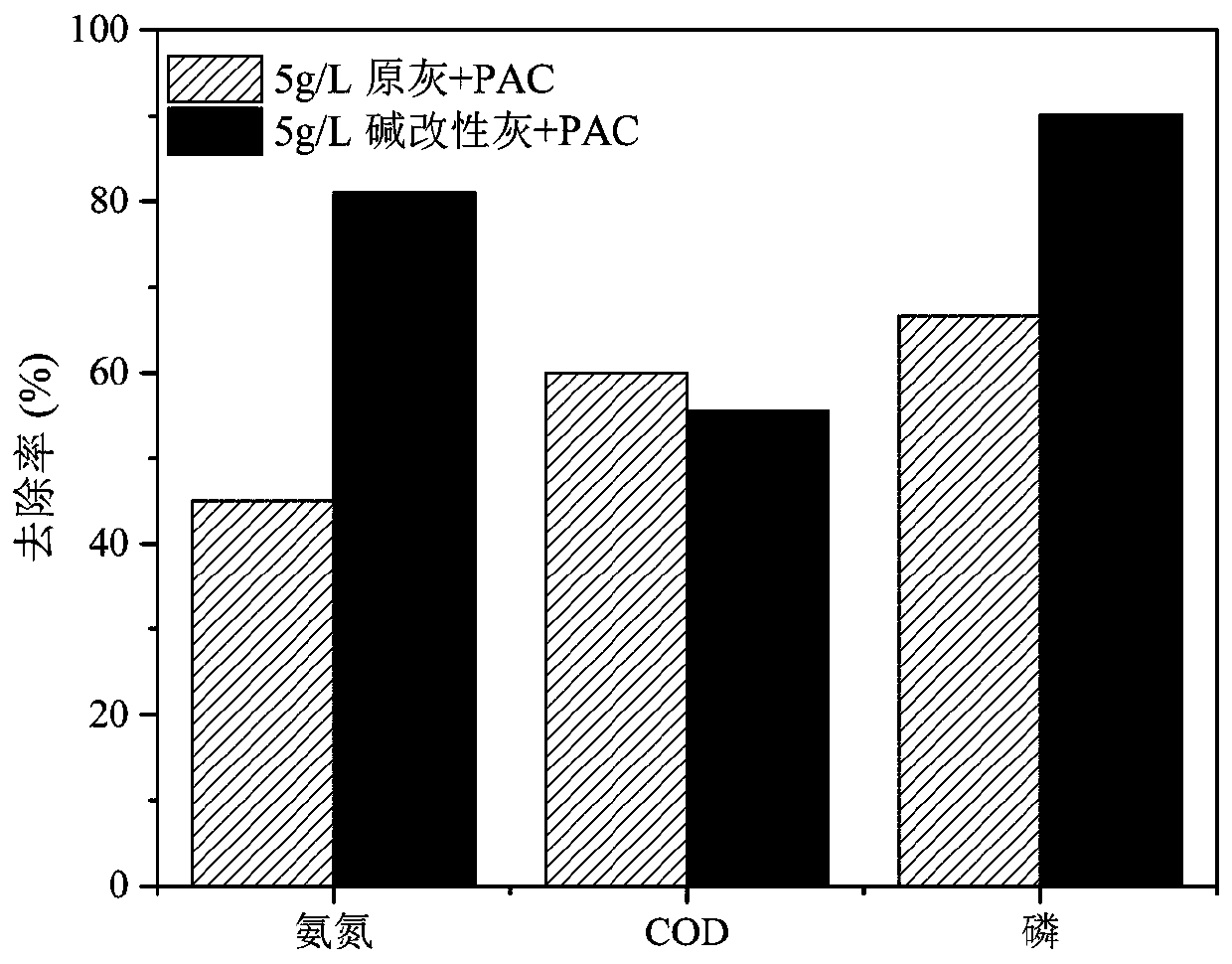

A fly ash and water purification technology, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as poor coagulation effect, poor settlement performance, and low treatment efficiency, and achieve increased Effects of ion exchange capacity and surface activity, improvement of adsorption capacity, and short settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

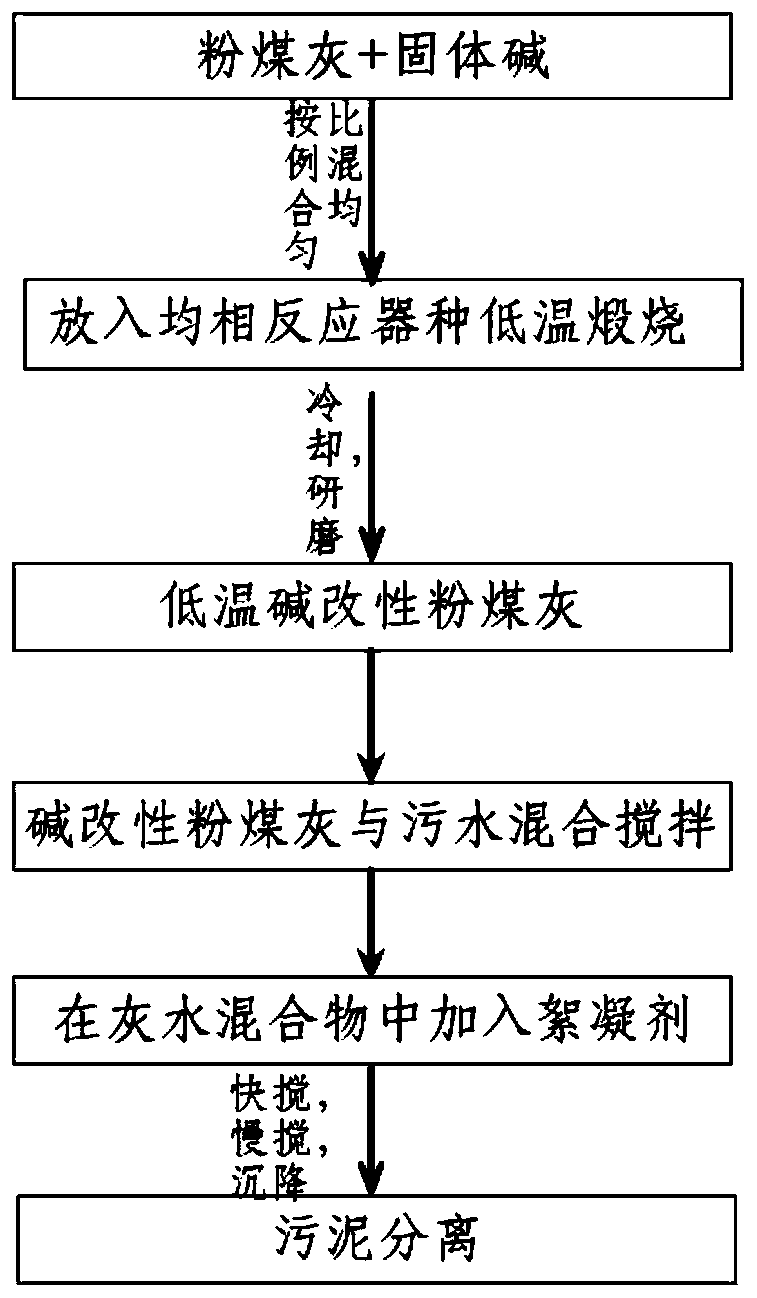

Method used

Image

Examples

Embodiment 1

[0056] (1) Raw material and formula

[0057] Fly ash is taken from Datong No. 2 Power Plant, with an average particle size of 20-30 μm.

[0058] Prepare the materials respectively according to the following formula, the total material of each formula is 100kg: fly ash: sodium hydroxide = 10:1.

[0059] The sewage is taken from the Wenyu River in Changping District, Beijing.

[0060] (2) Method

[0061] Specific steps are as follows:

[0062] 1) Mixing, according to the proportion of the above formula, fully mix the fly ash and sodium hydroxide to obtain the mixed material;

[0063] 2) The mixed material is placed in a rotary furnace, the calcination temperature is 200° C., and the reaction time is 2 hours, so that the mixed material is fully reacted. After cooling, the materials are taken out and ground for later use to obtain low-temperature alkali-modified fly ash.

[0064] 3) Add low-temperature alkali-modified fly ash to the sewage, the dosage is 5g / L, carry out adsor...

Embodiment 2

[0068] (1) Raw material and formula

[0069] Fly ash is taken from Datong No. 2 Power Plant, with an average particle size of 20-30 μm.

[0070] Prepare the materials respectively according to the following formula, the total material of each formula is 100kg: fly ash: solid alkali = 10:1.

[0071] The sewage is taken from the Wenyu River in Changping District, Beijing, and the solid alkali is potassium hydroxide.

[0072] (2) Method

[0073] Specific steps are as follows:

[0074] 1) Mixing, according to the ratio of the above formula, fully mix the fly ash and potassium hydroxide to obtain the mixed material;

[0075] 2) The mixed material is placed in a rotary furnace, the calcination temperature is 200° C., and the reaction time is 3 hours, so that the mixed material is fully reacted. After cooling, the materials are taken out and ground for later use to obtain low-temperature alkali-modified fly ash.

[0076] 3) Add low-temperature alkali fly ash to the sewage, the d...

Embodiment 3

[0079] (1) Raw material and formula

[0080] Fly ash is taken from Datong No. 2 Power Plant, with an average particle size of 20-30 μm.

[0081] Prepare the materials respectively according to the following formula, the total material of each formula is 100kg: fly ash: sodium hydroxide = 10:1.

[0082] Sewage is simulated wastewater containing heavy metals cadmium and nickel.

[0083] (2) Method

[0084] Specific steps are as follows:

[0085] 1) Mixing, according to the proportion of the above formula, fully mix the fly ash and sodium hydroxide to obtain the mixed material;

[0086] 2) The mixed material is placed in a rotary furnace, the calcination temperature is 200° C., and the reaction time is 2 hours, so that the mixed material is fully reacted. After cooling, the materials are taken out and ground for later use to obtain low-temperature alkali-modified fly ash.

[0087] 3) Add low-temperature alkali fly ash to the sewage, the dosage is 5g / L or 20g / L, adsorb at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com