Degradable disposable tableware material

A disposable and tableware technology, applied in the field of degradable materials, can solve the problems of complex components and low preparation efficiency of degradable plastics for disposable tableware, and achieve green, safe and environmentally friendly use and preparation processes, high preparation efficiency, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

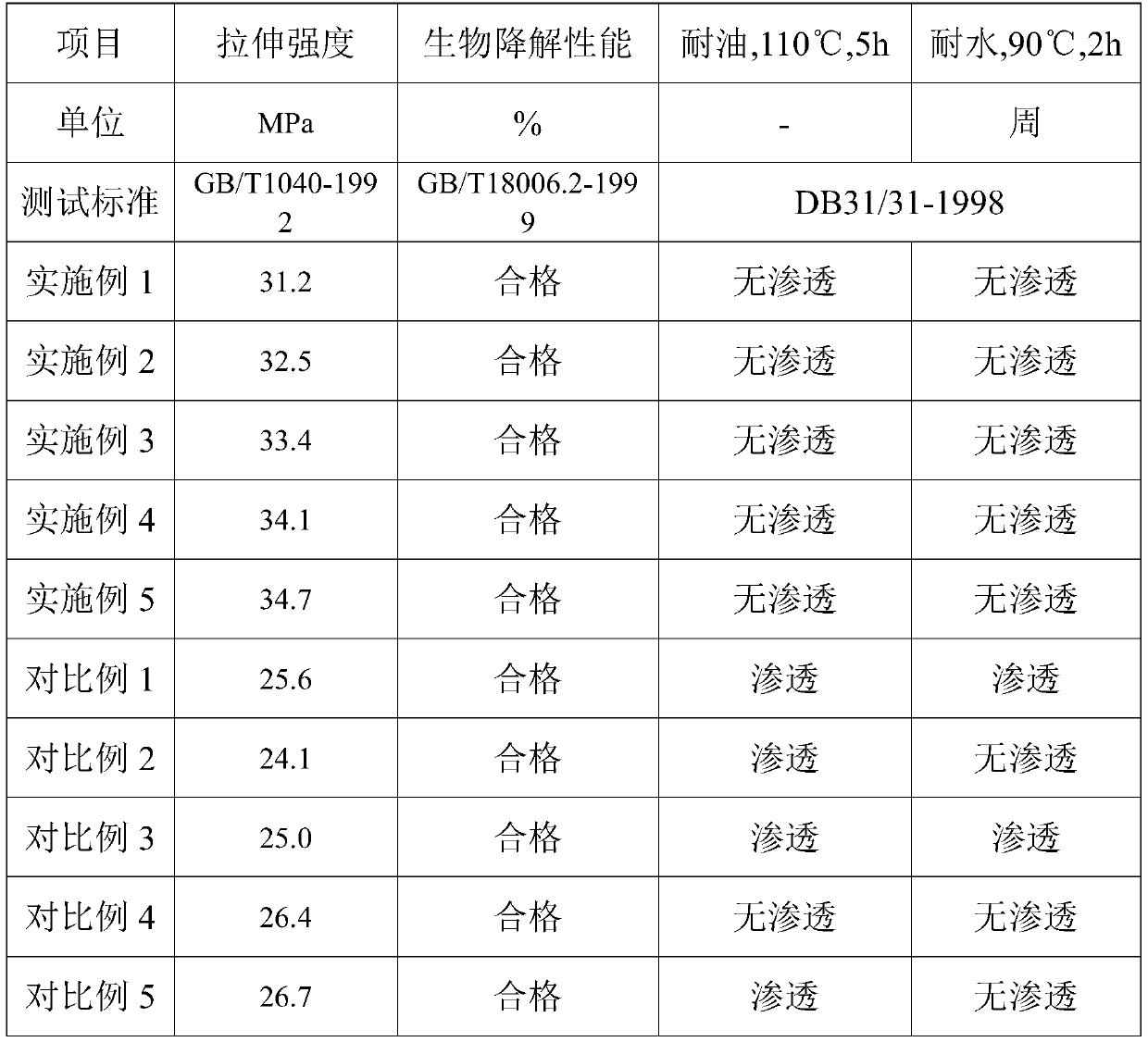

Examples

Embodiment 1

[0032] A degradable disposable tableware material is characterized in that it is made of the following raw materials in parts by weight: 35 parts of hyperbranched polylactic acid, 5 parts of puffed rice flour, 3 parts of molecular sieves, 8 parts of plant fiber powder, cinnamic acid / Linalool Oxidation / Tetrahydrofurfuryl Acrylate / Polyethylene Glycol Monoallyl Ether Copolymer 15 parts, Epoxy Soybean Oil 0.5 parts, Non-butyltin Esterification Catalyst KR-4100A 0.03 parts, Silane Coupling Agent KH550 0.5 part; the plant fiber powder is formed by pulverizing bamboo silk fibers after being dried.

[0033] The preparation method of described cinnamic acid / oxidized linalool / tetrahydrofurfuryl acrylate / polyethylene glycol monoallyl ether copolymer comprises the steps of: cinnamic acid, oxidized linalool, tetrahydrofurfuryl acrylic acid Ester, polyethylene glycol monoallyl ether, and azobisisobutyronitrile were added to dimethyl sulfoxide, stirred and reacted at 65°C for 3 hours in a n...

Embodiment 2

[0038] A degradable disposable tableware material is characterized in that it is made of the following raw materials in parts by weight: 40 parts of hyperbranched polylactic acid, 6 parts of puffed rice flour, 4 parts of molecular sieves, 9 parts of plant fiber powder, cinnamic acid / Oxidized linalool / tetrahydrofurfuryl acrylate / polyethylene glycol monoallyl ether copolymer 16 parts, epoxy butyl furfurate 0.7 parts, non-butyltin esterification catalyst KR-4100A 0.035 parts, silane coupling 0.7 parts of agent KH560; the plant fiber powder is dried and pulverized coconut palm fiber.

[0039] The preparation method of described cinnamic acid / oxidized linalool / tetrahydrofurfuryl acrylate / polyethylene glycol monoallyl ether copolymer comprises the steps of: cinnamic acid, oxidized linalool, tetrahydrofurfuryl acrylic acid Ester, polyethylene glycol monoallyl ether, and azobisisoheptanonitrile were added to N,N-dimethylformamide, stirred and reacted at 68°C for 3.5 hours in a helium...

Embodiment 3

[0044] A degradable disposable tableware material is characterized in that it is made of the following raw materials in parts by weight: 45 parts of hyperbranched polylactic acid, 7.5 parts of puffed rice flour, 4.5 parts of molecular sieves, 10 parts of plant fiber powder, cinnamic acid / Linalool oxide / tetrahydrofurfuryl acrylate / polyethylene glycol monoallyl ether copolymer 17 parts, tributyl citrate 1 part, non-butyltin esterification catalyst KR-4100A 0.04 parts, silane coupling agent 1 part of KH570; the plant fiber powder is dried and pulverized.

[0045] The preparation method of described cinnamic acid / oxidized linalool / tetrahydrofurfuryl acrylate / polyethylene glycol monoallyl ether copolymer comprises the steps of: cinnamic acid, oxidized linalool, tetrahydrofurfuryl acrylic acid Ester, polyethylene glycol monoallyl ether, and azobisisobutyronitrile were added to N,N-dimethylacetamide, stirred and reacted at 70°C for 4 hours in a neon atmosphere, and then the solvent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com