Reversible thermosensitive color-changing transformer early-warning insulating sheath material and preparation method thereof

An insulating sheath, heat-sensitive discoloration technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problems of poor high and low temperature resistance, easy to decompose, economic losses, etc., achieve good flame retardant effect, adjustable color, considerable economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

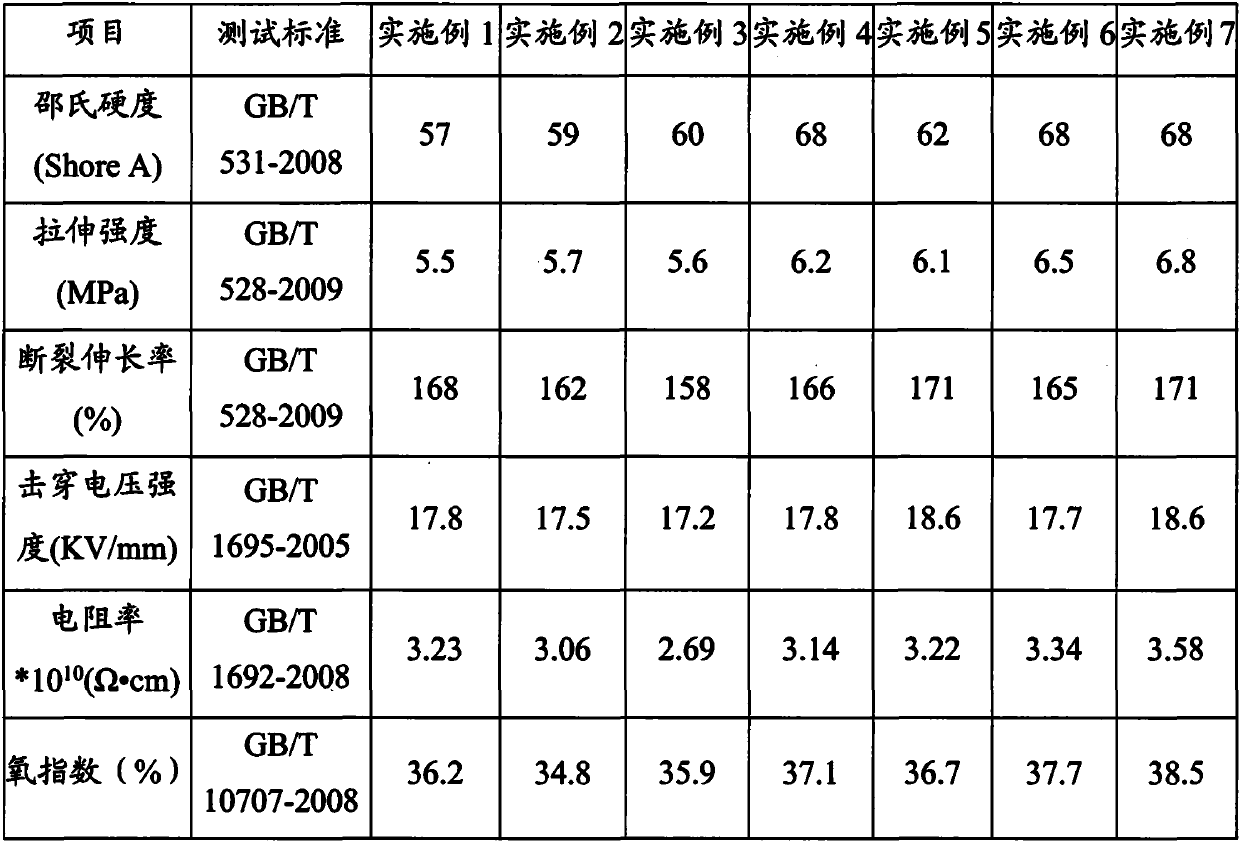

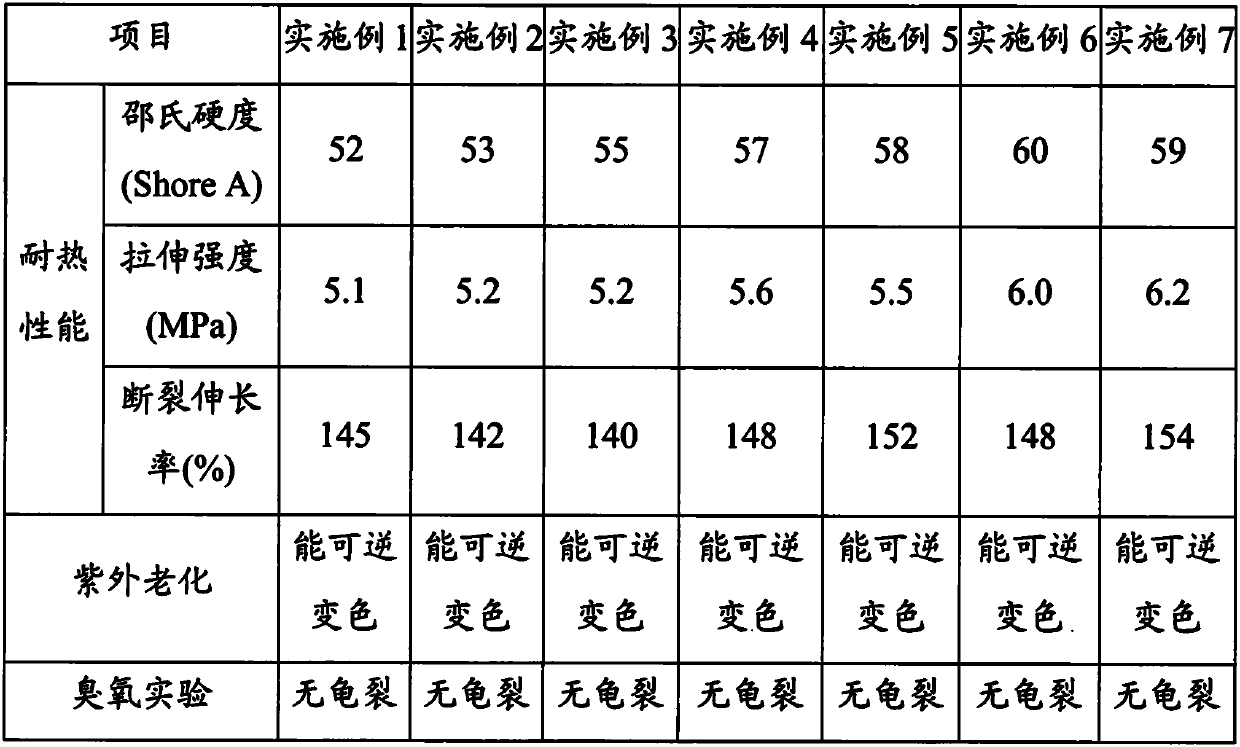

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the above-mentioned reversible thermochromic transformer early warning insulating sheath material, comprising the following steps:

[0041] (1) Use filling oil to fill the styrene-based thermoplastic elastomer with oil, and let it stand for 15-20min;

[0042] (2) adding the oil-filled styrene-based thermoplastic elastomer and the remaining components in the high-speed mixer through step (1) and mixing;

[0043] (3) step (2) gained mixture is added in Banbury mixer to carry out Banbury;

[0044] (4) feeding the mixture after the banburying in step (3) into a twin-screw extruder for pulling and dicing, to obtain a reversible thermochromic transformer early warning insulating sheath material.

[0045] In order to further optimize the above technical solution, the extrusion temperature in step (4) is 160-200°C.

Embodiment 1

[0047] An early warning insulating sheath material for a reversible thermochromic transformer, the sheath material includes the following raw material components and parts by weight:

[0048] 50 parts of silicone rubber, 15 parts of polypropylene resin, 10 parts of styrene thermoplastic elastomer, 15 parts of dioctyl maleate, 30 parts of fumed silica, 15 parts of nano wollastonite, 20 parts of reversible thermochromic material, 5 parts of white oil, 20 parts of ammonium polyphosphate, 20 parts of molybdenum trioxide, 3 parts of oxidized polyethylene wax, 5 parts of triallyl isocyanurate, 5 parts of antioxidant DLTP;

[0049] The preparation method of the reversible thermochromic material is as follows: firstly, according to the molar ratio of 1:5, weigh the required amount of cetyltrimethylammonium chloride C. 19 H 42 ClN and CoCl 2 ; Secondly, the hexadecyl trimethyl ammonium chloride C that will be weighed 19 H 42 ClN and metal cobalt salt are dissolved in ethanol or wat...

Embodiment 2

[0051] An early warning insulating sheath material for a reversible thermochromic transformer, the sheath material includes the following raw material components and parts by weight:

[0052] 80 parts of silicone rubber, 10 parts of polypropylene resin, 30 parts of styrene thermoplastic elastomer, 10 parts of dioctyl maleate, 40 parts of fumed silica, 20 parts of nano wollastonite, 10 parts of reversible thermochromic material, 3 parts of white oil, 10 parts of hypophosphite, 10 parts of magnesium hydroxide, 2 parts of SEBS grafted maleic anhydride, 3 parts of PP grafted maleic anhydride, 1 part of dicumyl peroxide, 1 part of antioxidant CPL ;

[0053] The preparation method of the reversible thermochromic material is as follows: firstly, according to the molar ratio of 1:6, weigh the required amount of cetyltrimethylammonium chloride C. 19 H 42 ClN and CoSO 4 ; Secondly, the hexadecyl trimethyl ammonium chloride C that will be weighed 19 H 42 ClN and metal cobalt salt ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com