High-elasticity environment-friendly latex paint and preparation method thereof

An environmentally friendly latex and high-elasticity technology, applied in the field of latex paint, can solve the problems of poor weather resistance and low elasticity, and achieve the effects of strong weather resistance, good film-forming process, and protection of light sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

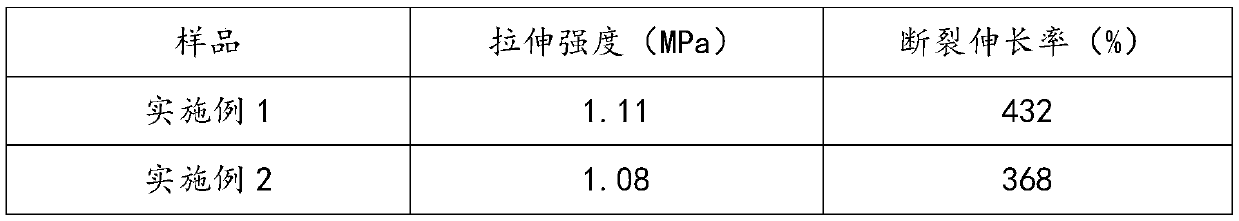

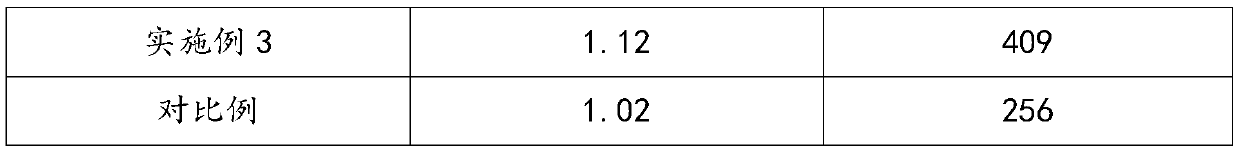

Examples

preparation example Construction

[0027] The preparation of modified acrylic acid emulsion, concrete preparation steps are as follows: (1) by comonomer methyl methacrylate 400g, styrene 230g, acrylic acid 350g, E-44 epoxy resin 30g and vinyltriethoxysilane 130g successively Add it into the reactor; (2) Add 456g of 40% mixed monomers into the reactor, start stirring, slowly add 32g of diethylene glycol butyl ether dropwise, after the dropwise addition, stir for 20-30min, then drop half of the amount Sodium persulfate (10%, 50mL) solution, after the dropwise addition, raise the temperature to 80-85°C, and keep it warm for 2-3h; (3) Then add 684g of the remaining mixed monomer dropwise, and the temperature rises after the dropwise addition When the temperature reaches 85-90°C, add the remaining sodium persulfate solution (10%, 50mL) dropwise. After the dropwise addition, keep warm for 2-3 hours and then drop to 40-45°C. Finally, add a small amount of ammonia water dropwise to adjust the pH value to medium propert...

Embodiment 1

[0031] This embodiment provides a novel high-elasticity environment-friendly latex paint. The latex paint comprises the following components by weight: 40 parts of water, 30 parts of modified acrylic emulsion, 18 parts of modified titanium dioxide, 6 parts of composite filler, water-washed kaolin 6 parts, 21 parts of heavy calcium carbonate, 1.8 parts of sodium lauryl sulfate, 0.3 parts of dimethylsiloxane defoamer, and 2.1 parts of composite film-forming aid.

[0032] The preparation method of described environment-friendly latex paint, concrete steps are as follows:

[0033] (1) Add 400 g of water, 300 g of modified acrylic emulsion, and 3 g of defoamer in corresponding parts by mass into the reaction kettle in sequence, and fully stir and mix to obtain the basic slurry;

[0034] (2) Add 180g of modified titanium dioxide, 60g of composite filler, 60g of washed kaolin, 210g of heavy calcium carbonate, 18g of sodium lauryl sulfate, 3g of dimethylsiloxane, and composite film-fo...

Embodiment 2

[0036]This embodiment provides a novel high-elasticity environment-friendly latex paint. The latex paint comprises the following components by weight: 35 parts of water, 35 parts of modified acrylic emulsion, 24 parts of modified titanium dioxide, 7 parts of composite filler, water-washed kaolin 5 parts, 18 parts of heavy calcium carbonate, 2 parts of sodium tripolyphosphate, 0.5 parts of dimethylsiloxane defoamer, and 2 parts of composite film-forming aid.

[0037] The preparation method is the same as in Example 1, only the corresponding proportions are replaced in equal amounts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com