Rare earth element extraction method, deep eutectic solvent and preparation method thereof

A technology of deep eutectic solvent and rare earth elements, applied in the direction of improving process efficiency, etc., can solve the problems of rare earth element extraction application research and no separation of rare earth elements, so as to reduce the consumption of process chemical substances and waste water discharge, and reduce the process Effects of chemical substance consumption, reduction and wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mix guanidine hydrochloride (GUC) and lactic acid (LAC) at a molar ratio of 1:4, and react with magnetic stirring at 70°C until the solid mixture becomes a clear and transparent homogeneous liquid phase to obtain a deep eutectic solvent of guanidine hydrochloride / lactic acid .

Embodiment 2

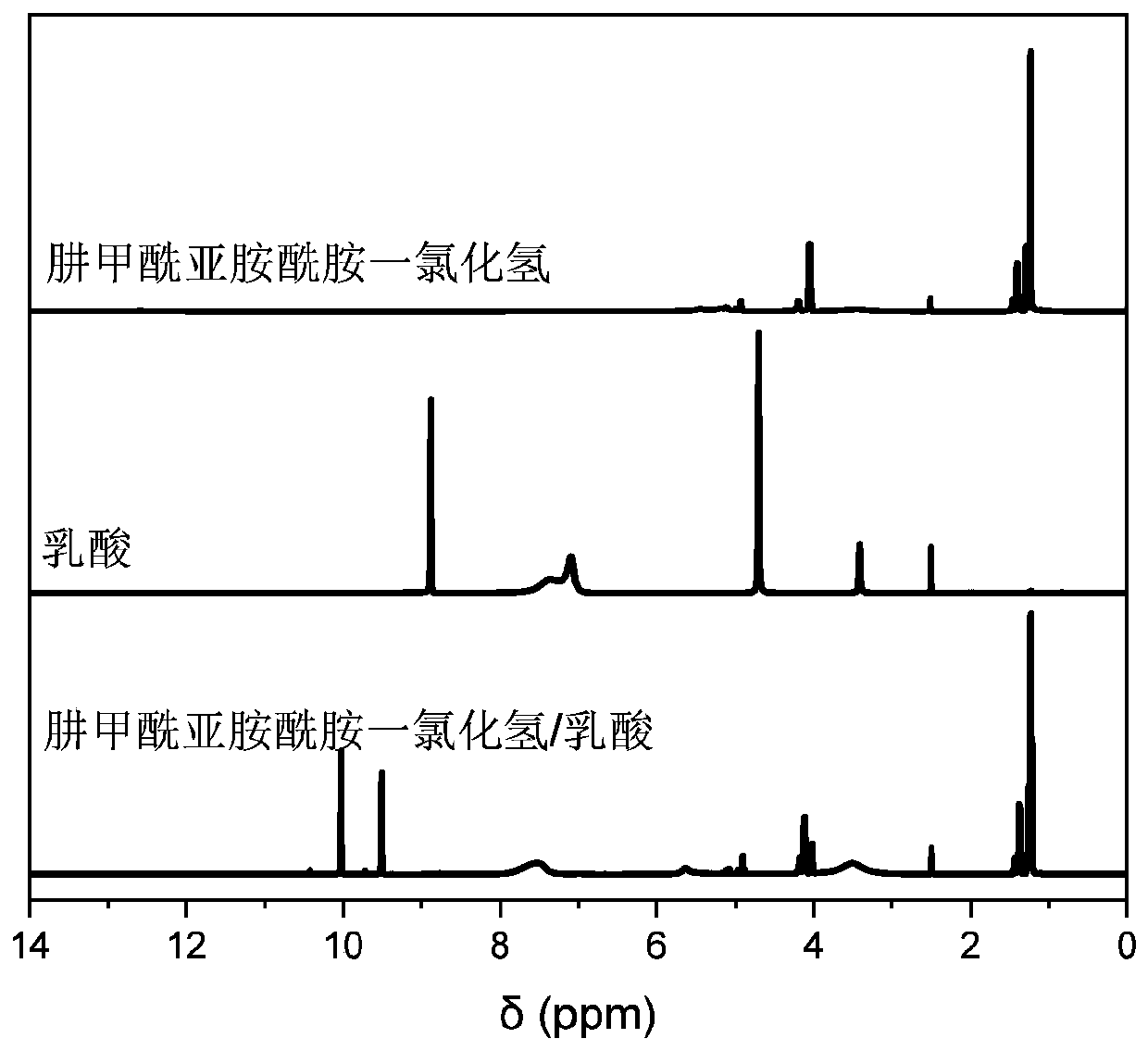

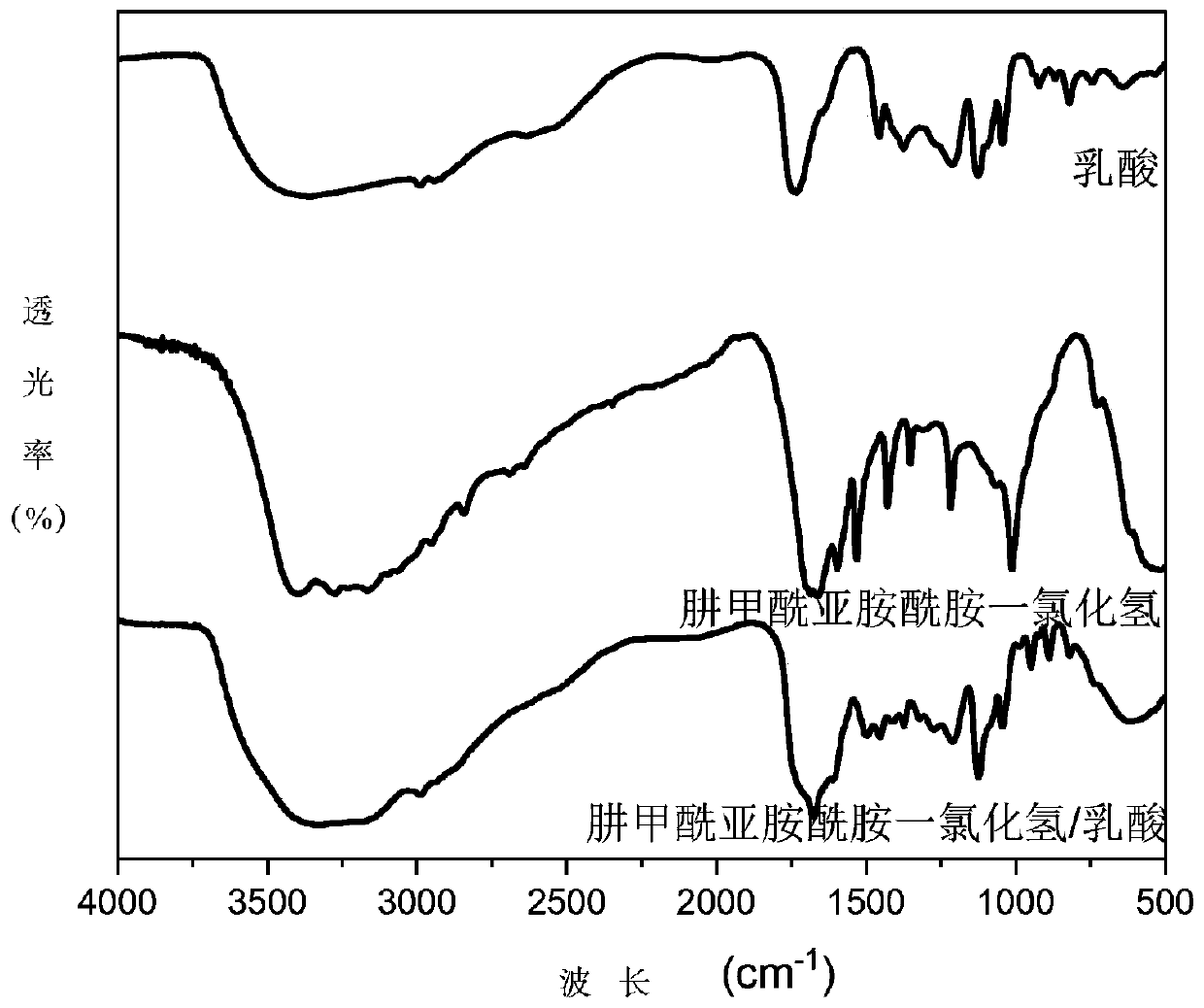

[0050] Mix hydrazinecarboximide amide monohydrogen chloride and lactic acid at a molar ratio of 1:2, and react with magnetic stirring at 50°C until the solid mixture becomes a clear and transparent homogeneous liquid phase to obtain hydrazinecarboximide amide monohydrogen chloride / lactic acid The deep eutectic solvent, its NMR figure is as follows figure 1 As shown, FTIR as figure 2 shown. from figure 1 It can be seen that the two raw materials did not react chemically, but formed a deep eutectic liquid phase system through hydrogen bonding.

Embodiment 3

[0052] Mix guanidine hydrochloride and glycerin at a molar ratio of 1:3, and react with magnetic stirring at 40°C until the solid mixture becomes a clear and transparent homogeneous liquid phase to obtain a deep eutectic solvent of guanidine hydrochloride / glycerol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com