Long-acting positive charge treatment process for melt-blown non-woven fabric for medical mask

A melt-blown non-woven fabric and processing technology, applied in fiber processing, biochemical fiber processing, textiles and papermaking, etc., can solve the problems of shortage of protective materials, short lifespan of masks, resource consumption, etc., and achieve good biocompatibility and Biodegradability, good broad-spectrum microbial inhibition, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

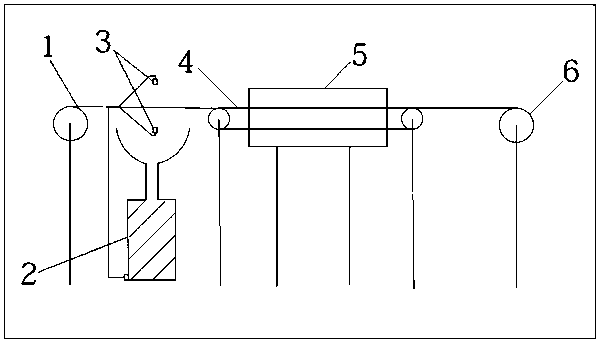

Image

Examples

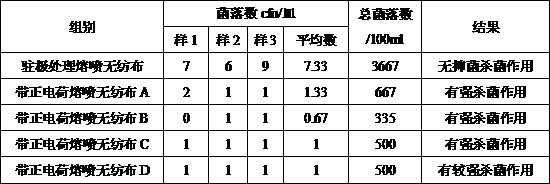

Embodiment 1

[0018] Weigh 0.3g of chitosan quaternary ammonium salt, add 300ml of 75% ethanol aqueous solution (v / v, the same below), stir the solution, and prepare a shell containing 0.1% (w / v, the same below) of chitosan quaternary ammonium salt Polysaccharide quaternary ammonium salt ethanol aqueous solution was used as the treatment liquid. Spray the treatment solution evenly on 200 g of melt-blown polypropylene non-woven fabric that is rotated and unfolded, and heat and dry in a vacuum at 40°C to obtain a melt-blown non-woven fabric A carrying a positively charged functional polymer material, making the non-woven fabric The mass fraction of the positively charged functional polymer material is 0.15% (w / w, the same below).

Embodiment 2

[0020] Take by weighing 5.0 g of starch quaternary ammonium salt, add 400 ml of 45% aqueous ethanol solution, stir and dissolve, and prepare a quaternary ammonium salt ethanol aqueous solution containing starch quaternary ammonium salt concentration of 1.25% as a treatment solution. Spray the treatment liquid evenly on 200 g of melt-blown polypropylene non-woven fabric that is rotated and unfolded, heat and dry at 50°C, and form a roll to prepare a positively charged functional polymer material melt-blown non-woven fabric B. The mass fraction of the cloth-carrying positively charged functional polymer material is 2.5%.

Embodiment 3

[0022] Weigh 1.2 g of chitosan quaternary ammonium salt, add 400 ml of 55% ethanol solution, stir and dissolve, and prepare a quaternary ammonium salt ethanol aqueous solution containing chitosan quaternary ammonium salt with a concentration of 0.3% as a treatment solution. Weigh 200g of cut and melt-blown polypropylene non-woven fabric, put it into the treatment solution and soak it evenly, absorb the ethanol aqueous solution of quaternary ammonium salt in the non-woven fabric, heat and dry under vacuum at 50°C, and obtain a positively charged functional polymer The material is melt-blown non-woven fabric C, so that the mass fraction of the non-woven fabric carrying positively charged functional polymer materials is 0.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com