Water-based siloxane coating for outer surface coating of non-stick pan

A siloxane and outer surface technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor color development, quality disputes, and high energy consumption, and achieve improved color stability, low surface tension, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

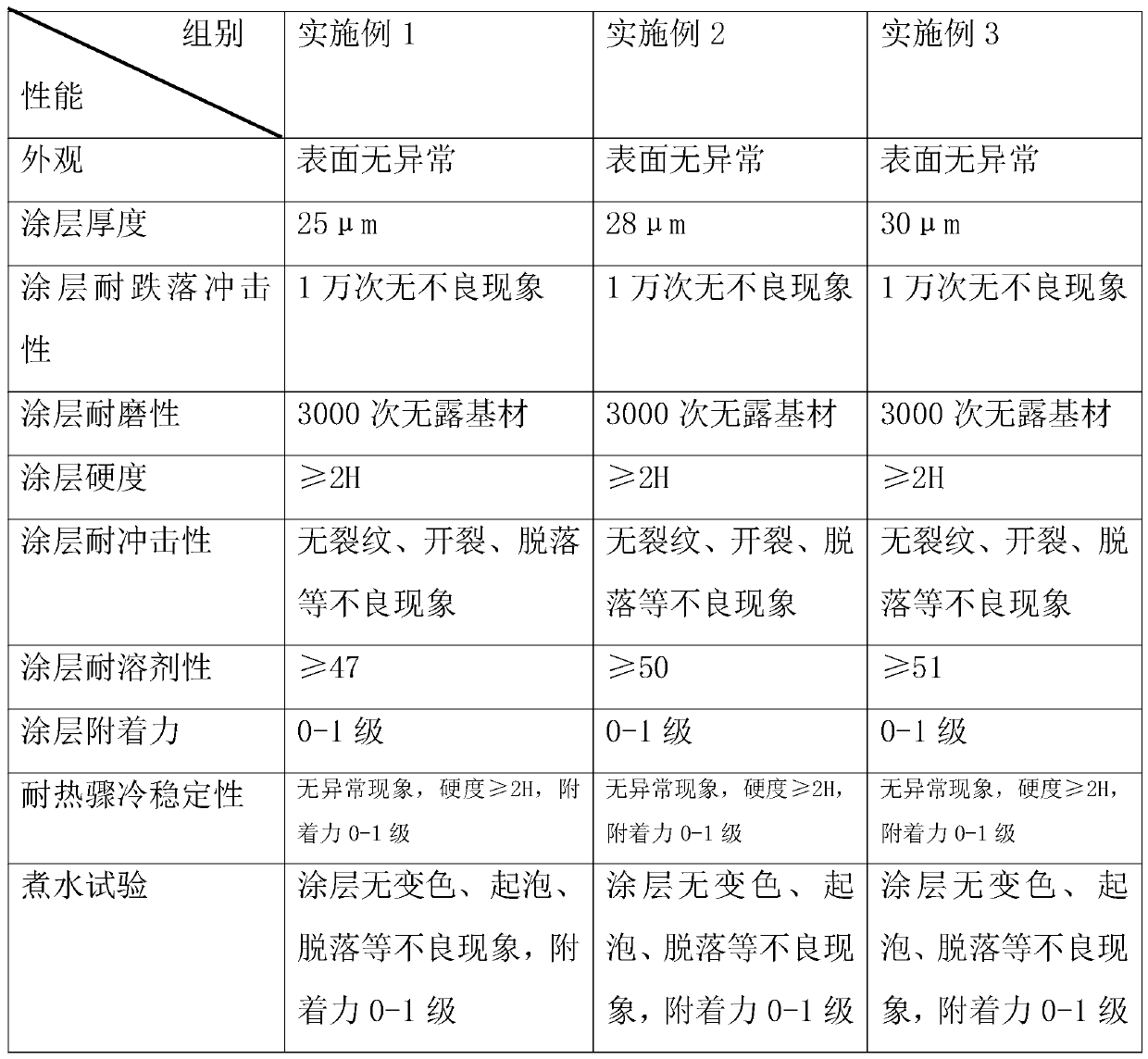

Examples

Embodiment 1

[0035] (1) Mix 10-25 parts of hybrid silane resin, 2-5 parts of dispersant, 0.2-0.5 parts of defoamer, 20-30 parts of water, 5-10 parts of propylene glycol methyl ether, 4 parts of diethylene glycol monobutyl ether -8 parts, add 4-8 parts of isopropanol into the mixing tank at 500r / min and stir for 10min, add 3-20 parts of pigment and stir at 800r / min for 30min;

[0036] (2) The mixture prepared in the above step (1) is sucked into a horizontal sand mill through an air pump, ground into a color paste, and set aside;

[0037] (3) 15 parts of hybrid silane resin, 10 parts of water-based sealing polyurethane, 10 parts of amino resin, 15-20 parts of water, 3-5 parts of propylene glycol methyl ether, 3-5 parts of diethylene glycol monobutyl ether, isopropyl Add 3-5 parts of alcohol into the mixing tank and stir at 500r / min for 10min, add the ground color paste, and stir at 800r / min for 30min to prepare a water-based silicone coating;

[0038] (4) The paint is sprayed on the surfac...

Embodiment 2

[0040] (1) Mix 10-25 parts of hybrid silane resin, 2-5 parts of dispersant, 0.2-0.5 parts of defoamer, 20-30 parts of water, 5-10 parts of propylene glycol methyl ether, 4 parts of diethylene glycol monobutyl ether -8 parts, add 4-8 parts of isopropanol into the mixing tank at 500r / min and stir for 10min, add 3-20 parts of pigment and stir at 800r / min for 30min;

[0041] (2) The mixture prepared in the above step (1) is sucked into a horizontal sand mill through an air pump, ground into a color paste, and set aside;

[0042] (3) 20 parts of hybrid silane resin, 5 parts of water-based sealing polyurethane, 10 parts of amino resin, 15-20 parts of water, 3-5 parts of propylene glycol methyl ether, 3-5 parts of diethylene glycol monobutyl ether, isopropyl Add 3-5 parts of alcohol into the mixing tank and stir at 500r / min for 10min, add the ground color paste, and stir at 800r / min for 30min to prepare a water-based silicone coating;

[0043] (4) The paint is sprayed on the surface...

Embodiment 3

[0045] (1) Mix 10-25 parts of hybrid silane resin, 2-5 parts of dispersant, 0.2-0.5 parts of defoamer, 20-30 parts of water, 5-10 parts of propylene glycol methyl ether, 4 parts of diethylene glycol monobutyl ether -8 parts, add 4-8 parts of isopropanol into the mixing tank at 500r / min and stir for 10min, add 3-20 parts of pigment and stir at 800r / min for 30min;

[0046] (2) The mixture prepared in the above step (1) is sucked into a horizontal sand mill through an air pump, ground into a color paste, and set aside;

[0047](3) 20 parts of hybrid silane resin, 10 parts of water-based sealing polyurethane, 15 parts of amino resin, 15-20 parts of water, 3-5 parts of propylene glycol methyl ether, 3-5 parts of diethylene glycol monobutyl ether, isopropyl Add 3-5 parts of alcohol into the mixing tank and stir at 500r / min for 10min, add the ground color paste, and stir at 800r / min for 30min to prepare a water-based silicone coating;

[0048] (4) The paint is sprayed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com