A rapid reuse method of cleaning waste liquid produced by an iron bucket crushing and cleaning system

A cleaning system and waste liquid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, multi-stage water treatment, etc. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

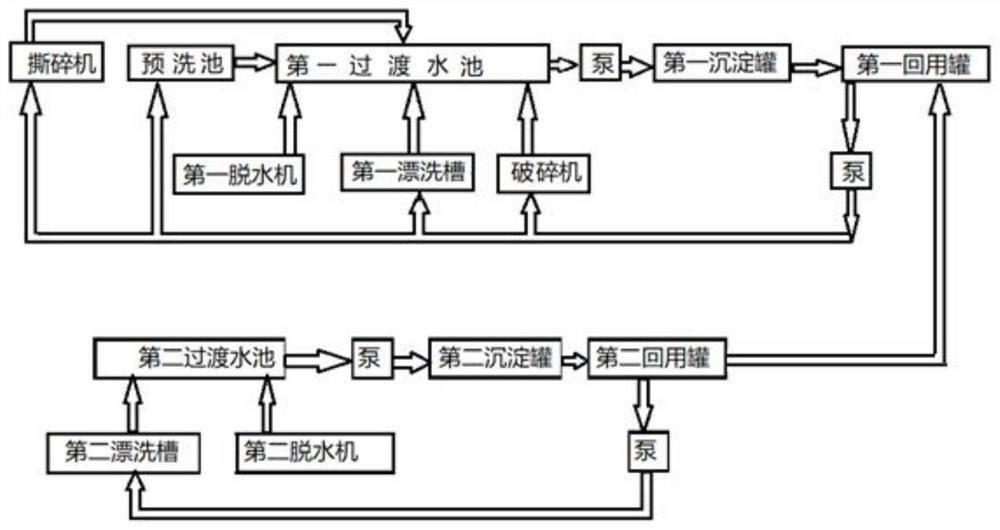

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Laboratory test

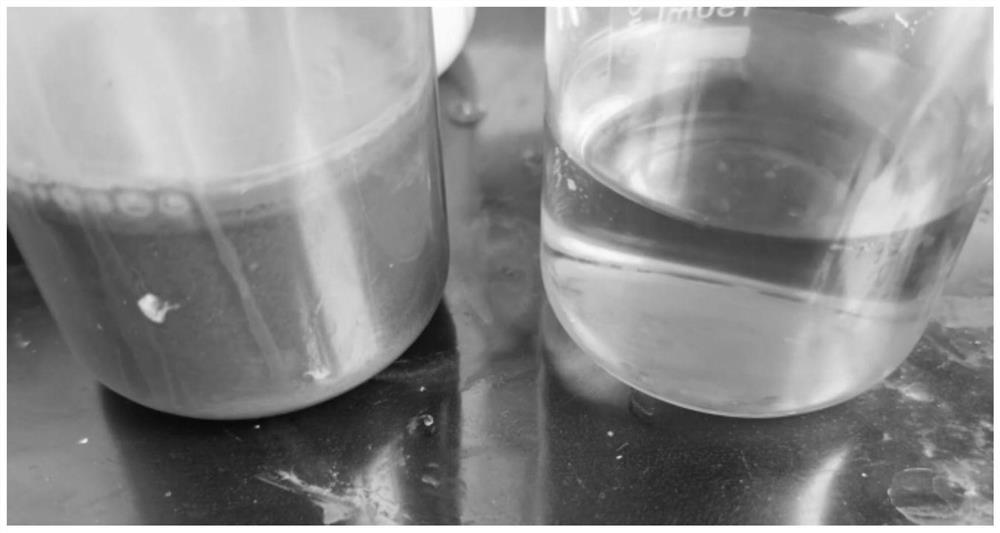

[0024] The first step: take 50ml of cleaning waste liquid and place it in a beaker, check that its pH value is 13, the standard suspended solids concentration is 1,600,000ppm, and the petroleum concentration is 400,000ppm, and let it stand for 15 minutes. During the standing process, the cleaning liquid waste liquid is gradually divided into upper , middle and lower layers, the colors are dark gray, reddish brown and gray respectively, use the oil separator to remove the oil slick on the upper layer, and leave the solution in the lower layer;

[0025] The second step: add concentrated sulfuric acid to the beaker, adjust the pH value to 4, and leave it to react for 15 minutes. At this time, the washing waste liquid separates out reddish-brown flocs to achieve the demulsification effect;

[0026] The third step: add 1ml of treatment agent to the beaker, and stir for 15s to carry out the first flocculation and decolorization. The main component...

Embodiment 2

[0032] Example 2: On-site treatment of the waste liquid produced by the applicant in the production process

[0033] When the cleaning solution in the production system is used for 30 days, it is found that the concentration of suspended particles in the cleaning solution is too high, which cannot guarantee the cleaning effect of the hazardous waste iron drum. At this time, it is necessary to effectively treat the cleaning waste liquid. In the liquid treatment tank, the standard suspended solids concentration in the waste liquid was 1,700,000 ppm, the petroleum concentration was 300,000 ppm, and the pH value was 14;

[0034] The first step: the cleaning waste liquid in the waste liquid treatment tank is left to settle for 20 minutes, and the cleaning waste liquid is gradually layered, and the colors are dark gray, reddish brown and gray from top to bottom. Leave the remaining layer solution;

[0035] The second step: add concentrated sulfuric acid to the waste liquid treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com