Medical wrist strap material for thermal transfer ribbon printing and preparation method thereof

A wristband and carbon ribbon technology, which is applied in the field of medical wristband materials and its preparation, can solve problems such as cracking, curling, and poor wearing comfort of composite films, and achieve the effects of not being easily stretched and deformed, ensuring correctness, and reducing surface energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

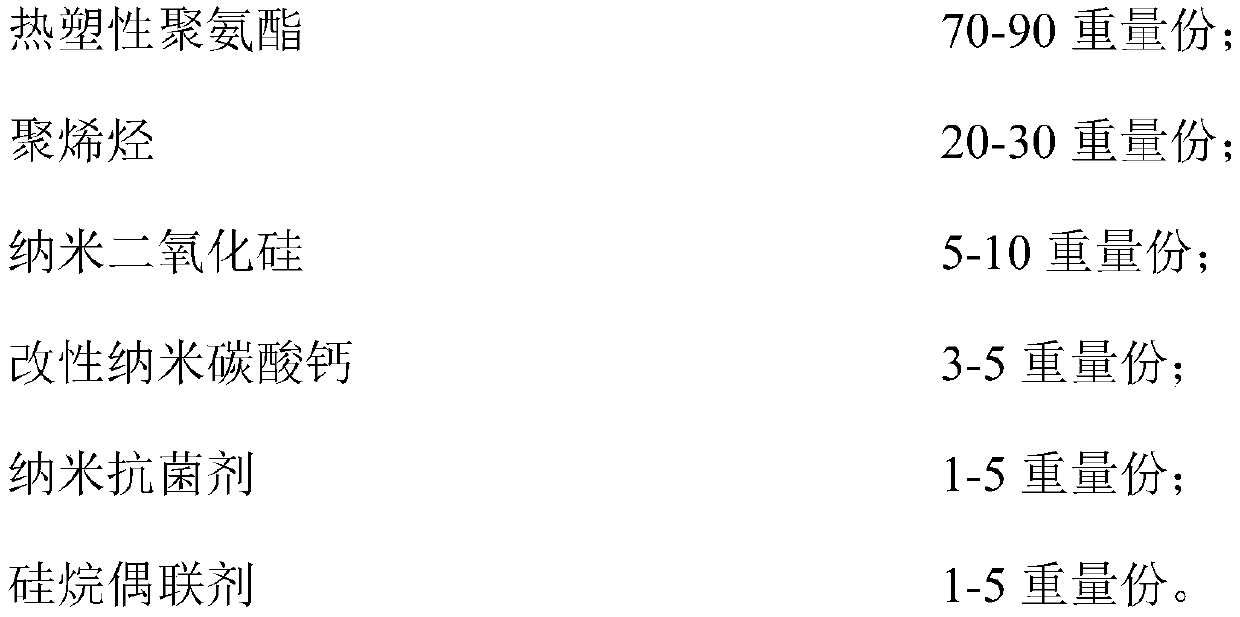

[0042] A medical wristband material for carbon ribbon printing, consisting of the following components in parts by weight:

[0043]

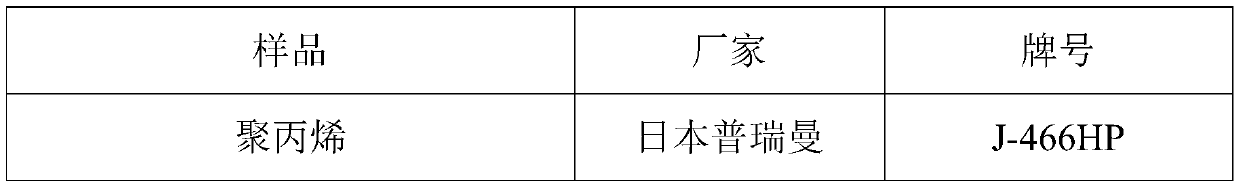

[0044] Among them, the polyolefin is a combination of polypropylene and ethylene-vinyl acetate copolymer with a mass ratio of 1:1; the nano-silica particle size is 50±5 μm; the silane coupling agent is vinyltrimethoxysilane.

[0045] The preparation method is as follows:

[0046](1) Nano-silica and graphene nanosheets are mixed at a stirring rate of 100r / min, and then uniformly mixed with a silane coupling agent at a stirring rate of 100r / min to obtain the first mixture;

[0047] (2) Mix the first mixture, polyolefin, antibacterial agent and thermoplastic polyurethane at a stirring rate of 200r / min, then dry at 90°C for 5h, and finally extrude with a single-screw extruder, cast against pressure, and cool , trimming, and pressurizing to obtain the medical wristband material for ribbon printing;

[0048] The temperature of the feeding section...

Embodiment 2

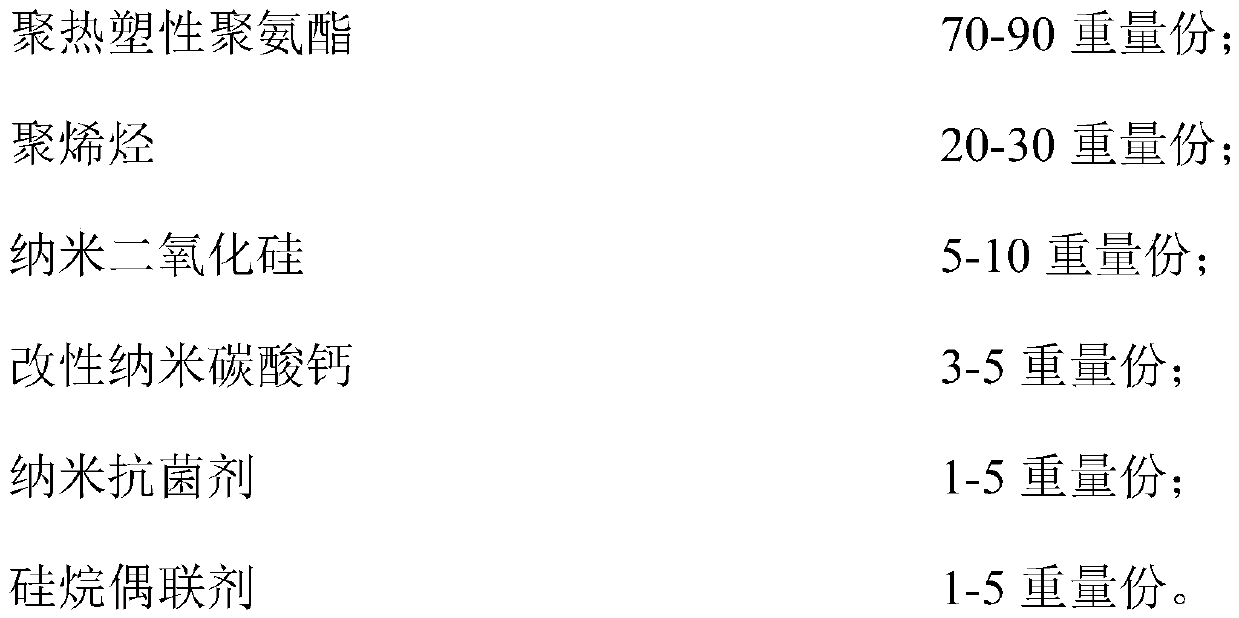

[0050] A medical wristband material for carbon ribbon printing, consisting of the following components in parts by weight:

[0051]

[0052] Among them, the polyolefin is a combination of polypropylene and ethylene-vinyl acetate copolymer with a mass ratio of 1:1; the nano-silica particle size is 50±5 μm; the silane coupling agent is vinyltrimethoxysilane.

[0053] The preparation method is as follows:

[0054] (1) Nano-silica and graphene nanosheets are mixed at a stirring rate of 131r / min, and then mixed uniformly with a silane coupling agent at a stirring rate of 131r / min to obtain the first mixture;

[0055] (2) Mix the first mixture, polyolefin, antibacterial agent and thermoplastic polyurethane at a stirring rate of 300r / min, then dry at 85°C for 6h, and finally extrude with a single-screw extruder, cast against pressure, and cool , trimming, and pressurizing to obtain the medical wristband material for ribbon printing;

[0056] The temperature of the feeding sectio...

Embodiment 3

[0058] A medical wristband material for carbon ribbon printing, consisting of the following components in parts by weight:

[0059]

[0060] Among them, the polyolefin is a combination of polypropylene and ethylene-vinyl acetate copolymer, the mass ratio is 1:1; the particle size of nano-silica is 50±5μm; the silane coupling agent is vinyl tris(β-methoxyethoxy base) silane.

[0061] The preparation method is as follows:

[0062] (1) Nano-silica and graphene nanosheets are mixed at a stirring rate of 150r / min, and then uniformly mixed with a silane coupling agent at a stirring rate of 150r / min to obtain the first mixture;

[0063] (2) Mix the first mixture, polyolefin, antibacterial agent and thermoplastic polyurethane at a stirring rate of 240r / min, then dry at 100°C for 4h, and finally extrude with a single-screw extruder, cast against pressure, and cool , trimming, and pressurizing to obtain the medical wristband material for ribbon printing;

[0064] The temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com