Preparation method of polyacrylonitrile-based composite loose nanofiltration membrane

A polyacrylonitrile-based membrane, polyacrylonitrile-based technology, applied in the field of membrane separation, can solve the problems of low permeation flux, poor hydrophilicity, instability, etc., and achieve good anti-pollution performance, low cost and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

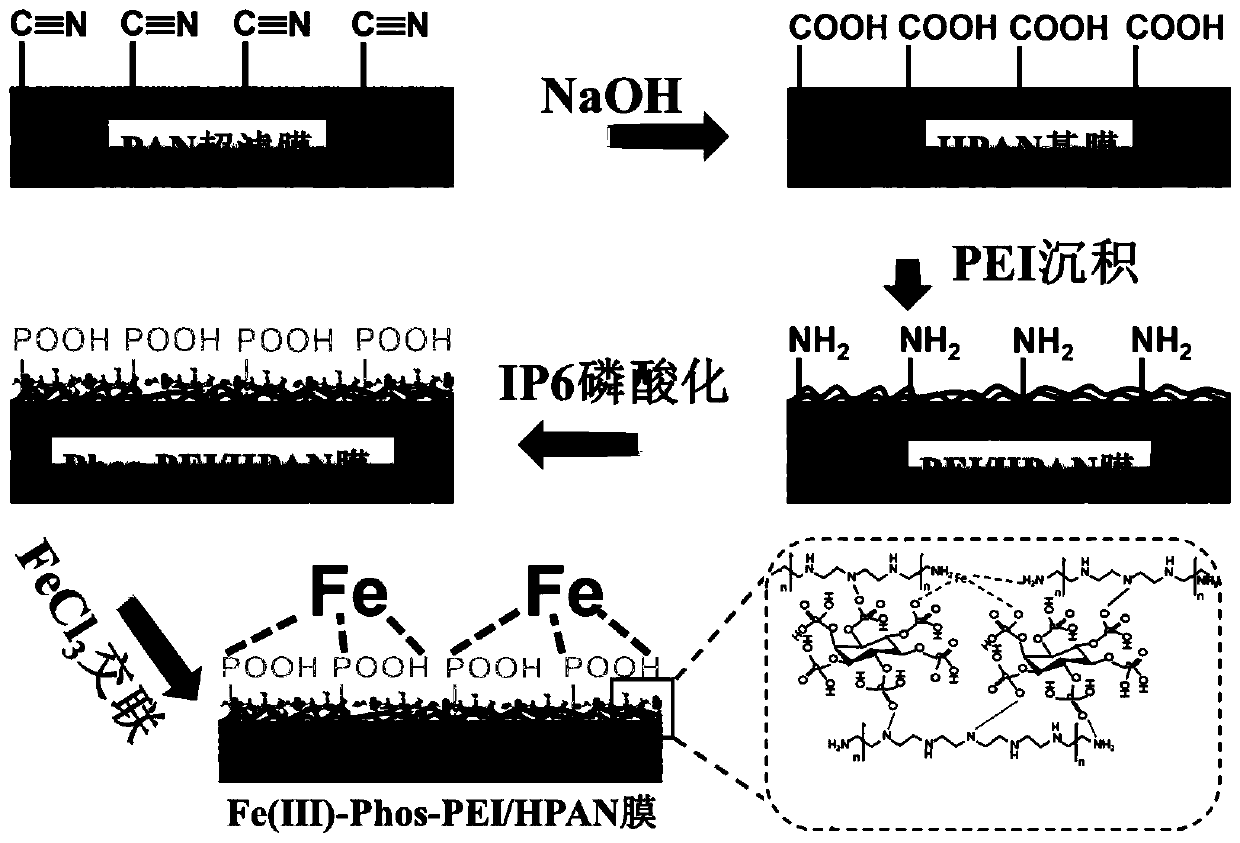

[0029] In the first step, the polyacrylonitrile (PAN) ultrafiltration membrane is immersed in 2mol / L NaOH aqueous solution for hydrolysis modification, the hydrolysis temperature is 45±1°C, and the hydrolysis time is 30-40min. After the hydrolysis is completed, rinse with deionized water several times to remove the residual alkali on the surface of the membrane until the rinse water is neutral, that is, the basement membrane (HPAN) with carboxyl groups distributed on the surface is obtained;

[0030] In the second step, immerse the base film of step (1) in a 3wt% polyethyleneimine (PEI) aqueous solution, put it in a vacuum oven at 45±1°C for 30-40min, take it out, and rinse it with deionized water for 3 After removing the unreacted PEI for the first time, put it into a vacuum oven and dry it to obtain a composite film (PEI / HPAN) coated with a polymer;

[0031] In the third step, the PEI / HPAN membrane was soaked in 0.3wt% phytate (IP6) aqueous solution for 3 minutes, and then p...

Embodiment 2

[0034] The concentration of polyethyleneimine (PEI) in Step 2 in Example 1 was adjusted to 1 wt%, and the rest of the conditions were the same as in Example 1. The prepared composite loose nanofiltration membrane has a rejection rate of 91.29% and a permeation flux of 15.59L / m at 20±1°C, 0.2MPa of 100mg / L crystal violet aqueous solution 2 h.

Embodiment 3

[0036] The concentration of polyethyleneimine (PEI) in Step 2 in Example 1 was adjusted to 2 wt%, and the rest of the conditions were the same as in Example 1. The prepared composite loose nanofiltration membrane has a rejection rate of 94.44% and a permeation flux of 10.91L / m at 20±1°C, 0.2MPa of 100mg / L crystal violet aqueous solution 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com