Method for preparing cavity confinement in-situ growth large-area quasi-monocrystalline perovskite thin film

An in-situ growth and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems that are not conducive to the removal of single-crystal perovskite films, are not conducive to high efficiency, and have high resistance , to achieve the effect of being conducive to commercial large-scale production, promoting uniform and rapid growth, and the method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) FA 0.85 MA 0.15 PB 2.55 Br 0.45Preparation of perovskite precursor solution: mix 1.02mol FAI, 1.02mol PbI 2 , 0.18mol MABr and 0.18mol PbBr 2 Add it into 1L γ-butyrolactone, stir at 80°C for 6 hours, and prepare FA with a total concentration of 1.2mol / L 0.85 MA 0.15 PB 2.55 Br 0.45 Perovskite precursor (among them, MA + for CH 3 NH 3 + ,FA + for HC (NH 2 ) 2 + );

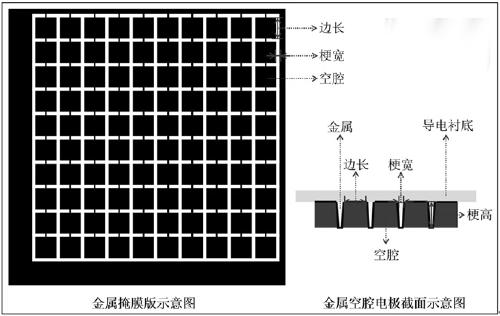

[0029] (2) Construction of the substrate containing aminated graphene quantum dots: on a cleaned transparent conductive substrate of 15 cm × 15 cm, the vacuum thermal evaporation method was used to use a square mask with a side length of 10 mm and a stem width of 0.05 mm. film plate, prepare a square tin metal cavity electrode, its side length, stem width, and stem height are 10 mm, 0.05 mm, and 300 nanometers; Prepare a 100nm-thick tin dioxide electron transport layer on the surface of the cavity electrode; finally, electrophoresis is used to deposit aminated graphene quantum dots on the...

Embodiment 2

[0033] (1) FA 0.85 MA 0.15 PB 2.55 Br 0.45 Preparation of perovskite precursor solution: mix 1.02mol FAI, 1.02mol PbI 2 , 0.18mol MABr and 0.18mol PbBr 2 Add it into 1L γ-butyrolactone, stir at 80°C for 6 hours, and prepare FA with a total concentration of 1.2mol / L 0.85 MA 0.15 PB 2.55 Br 0.45 Perovskite precursor (among them, MA + for CH 3 NH 3 + ,FA + for HC (NH 2 ) 2 + );

[0034] (2) Construction of substrates containing thiolated graphene quantum dots: On a cleaned transparent conductive substrate of 15 cm × 15 cm, vacuum thermal evaporation is used to utilize a regular hexagon with a side length of 10 mm and a stem width of 0.05 mm. A regular hexagonal titanium metal cavity electrode is prepared by using a mask plate, and its side length, stem width, and stem height are 10 mm, 0.05 mm, and 300 nm, respectively; Prepare a 100nm-thick titanium dioxide electron transport layer on the surface of the titanium metal cavity electrode; finally, electrophoresis i...

Embodiment 3

[0038] (1) MAPbI 3 Preparation of perovskite precursor solution: MAI and PbI 2 Add it into a mixed solvent of N,N-dimethylformamide and dimethyl sulfoxide with a volume ratio of 4:1 in an equimolar ratio, stir at 70°C for 6 hours, and prepare MAPbI with a concentration of 1.2mol / L 3 Perovskite precursor (among them, MA + for CH 3 NH 3 + );

[0039] (2) Construction of the substrate containing aminated graphene quantum dots: on a cleaned transparent conductive substrate of 15 cm × 15 cm, the vacuum thermal evaporation method was used to use a square mask with a side length of 10 mm and a stem width of 0.05 mm. stencil (eg figure 1 shown), prepare a square tin metal cavity electrode, whose side length, stem width, and stem height are 10 mm, 0.05 mm, and 200 nm, respectively; Prepare a 100nm-thick tin dioxide electron transport layer on the surface of the cavity electrode; finally, electrophoresis is used to deposit aminated graphene quantum dots on the surface of the tin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com