Integrated scaffold for simulating gradient structure from bone-tendon-bone mineralization to non-mineralization

A technology of mineral and mineral content, applied in the field of tendon/ligament stents, can solve the problem of inability to simulate the natural tendon-bone junction mineralization to non-mineralization gradient structure, etc., and achieves fine woven structure, high strength and good sports feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Extraction of silk fibroin: Weigh 60g silkworm cocoons and cut them into several layers, put them into 0.5% sodium bicarbonate aqueous solution and boil for 30 minutes, repeat twice to remove surface sericin, fully wash with deionized water, and dry in the air. Obtain silk fibroin fibers. Place silk fibroin fibers in CaCl 2 / H 2 O / absolute ethanol (molar ratio: 1:8:2) ternary solvent, heated to 70°C to dissolve for 40 minutes, then put into a dialysis bag with a molecular weight cut-off of 14000Da and dialyzed at room temperature for 7 days, and filtered the solution to obtain pure The silk fibroin aqueous solution is freeze-dried to obtain spongy silk fibroin.

[0054] (2) Preparation of spinning solution: Weigh 0.6g of P(LLA-CL) (75:25) with a molecular weight of about 200,000 (purchased from Jinan Daigang Biotechnology Co., Ltd.) and 0.2g of silk fibroin in 10mL Hexafluoroisopropanol (purchased from Shanghai Darui Fine Chemicals Co., Ltd.) was prepared into PL...

Embodiment 2

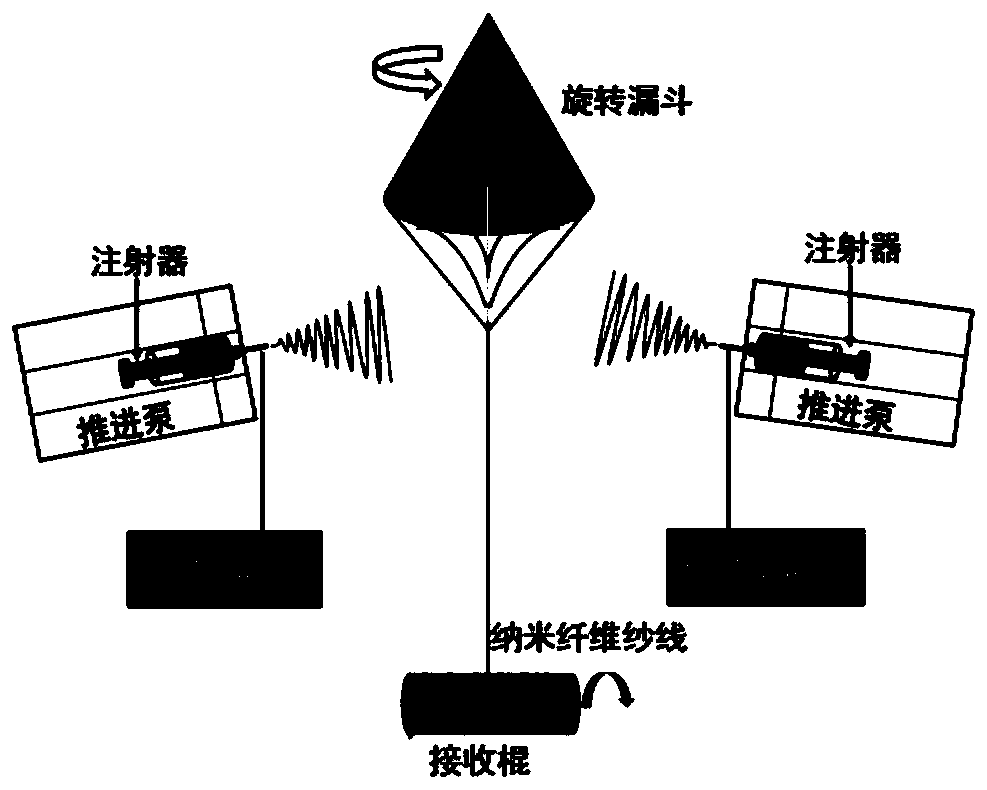

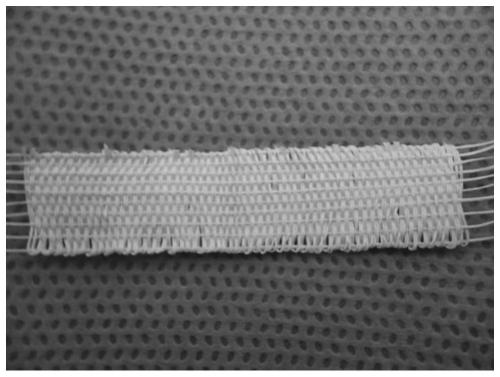

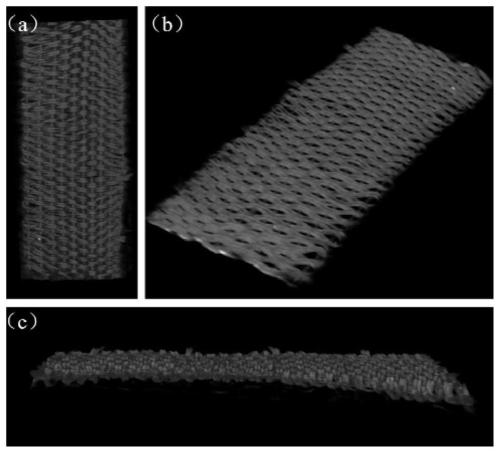

[0060] (1) Preparation of a mineralized to non-mineralized gradient structural integrated scaffold: PPS-0% HA nanofiber yarns are used as warp yarns, and PLA-PLCL / SF / HA nanofiber yarns loaded with different mineral contents are used as weft yarns, The weft thread in the middle part of the bracket is PLA-PLCL / SF yarn with zero mineral content, and the PPS-5%HA, PPS-10%HA, PPS-15%HA nanofiber yarn is used as the weft thread in the middle to both ends. The nanofiber yarns in warp and weft directions are interwoven by a weaving method to prepare a mineralized to non-mineralized gradient structural integrated scaffold.

[0061] (2) The weaving process of the above steps (1) is: on the semi-automatic weaving machine, use PPS-0% HA nanofiber yarn as the warp, and the distance between the two warps is 0.5~2mm. 10 warp threads; PPS-0% HA is used as the weft thread in the middle of the bracket, and PPS-5% HA, PPS-10% HA, and PPS-15% HA are used as the weft thread in sequence from the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com