Three-dimensional structure made of material containing polyhydroxyalkanoate, kit for preparation of bone filling material, and intramedullary nail

A polyhydroxyalkanoate and filling material technology, applied in the field of intramedullary nails, can solve the problems of inability to meet bending, tensile strength, damage to body tissue, bone adhesion, etc., and achieve excellent biodegradation properties, The effect of promoting bone regeneration and improving bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

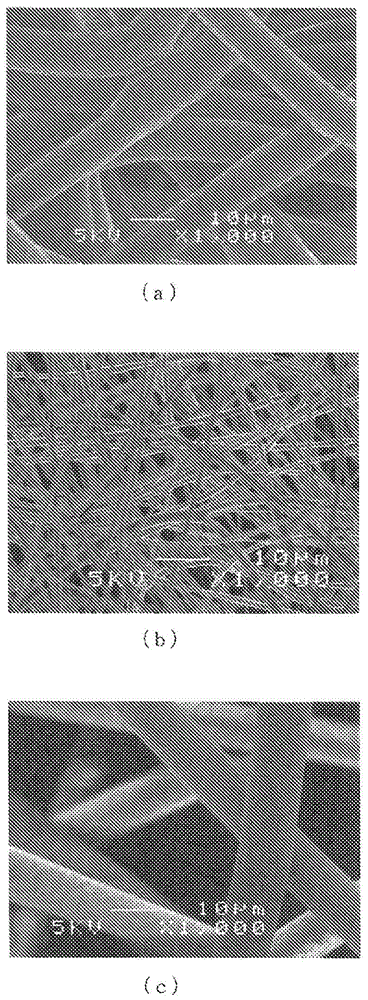

[0096] 2 g of PHA-18 was dissolved in chloroform so that the PHA concentration became 6% by weight. At this time, the viscosity of the solution was 2.8 Pa·s. 10 mL of the above solution was put into a glass syringe. Roll aluminum foil on a grounded rotating drum to act as a collector. Install a 22G injection needle, apply a voltage of 10kV, make the needle part positively charged, extrude at 0.35mm / min, spin on the collector, and produce a non-woven fabric with a thickness of 0.1mm. The fiber diameter is about 10 μm. The melting point and glass transition temperature of the obtained nonwoven fabric were measured using a differential scanning calorimeter. As a result, the melting point was 130°C and the glass transition temperature was -20°C.

Embodiment 2

[0105] 4 g of PHA-18L was dissolved in chloroform so that the PHA concentration became 6% by weight. At this time, the viscosity of the solution was 2.8 Pa·s. 10 mL of the above solution was put into a glass syringe. 1.5 L of ethanol was filled into a 400×200×40 mm plastic pan, and a grounded stainless steel plate with a diameter of 10 mm sank to the bottom. A 22G injection needle was attached to the syringe, and a voltage of 10 kV was applied to positively charge the needle portion, extruded at 0.35 mm / min, and spun in ethanol. The floating fibers were recovered with tweezers, placed on filter paper, and dried at room temperature. The diameter of the fibers is about 10 μm. The melting point and glass transition temperature of the obtained spongy substance were measured using a differential scanning calorimeter, and the melting point was 130°C, and the glass transition temperature was -20°C.

Embodiment 3

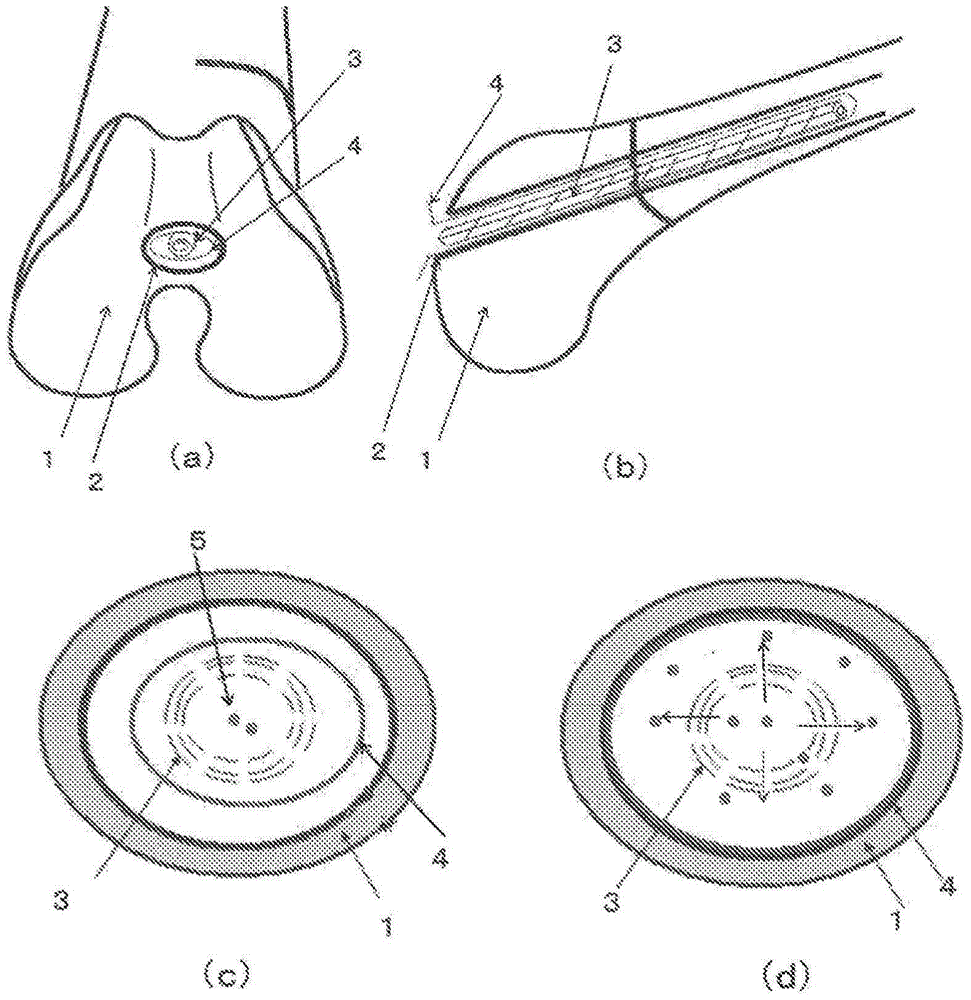

[0113] Silicone resin was poured into a glass bottle with a diameter of 15 mm and a length of 50 mm and cured while the bottle was tilted, thereby making a model of an uneven shape in which the silicone resin was tilted from the entire bottom of the bottle to one end of the cap. Then, the non-woven fabric prepared in the above-mentioned Example 1 was made into a bag shape, installed at the front end of the injection syringe in BIOPEX-R (Advanced Flowset), and the root was tied with silk thread to fix it. Prepare the BIOPEX paste according to the attached instructions except that the stirring method and filling method are set to 6 mL set and liquid volume 4.0 mL. Next, an injection syringe equipped with a nonwoven fabric was inserted into the non-uniform shape model prepared as above, and the prepared BIOPEX was injected using a syringe in a fixed amount (set).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com