Drug sustained-release hydrogel semi-embedded composite scaffold and preparation method thereof

A composite scaffold and hydrogel technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of immune rejection limitation, side effects of clinical therapy, etc., to promote bone growth, great clinical application value, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

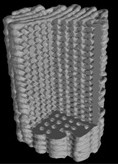

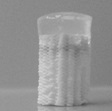

[0041]In this embodiment, a method for preparing a drug sustained-release hydrogel semi-embedded composite stent includes the following steps:

[0042](1) Preparation of Alendronate Sodium (ALN) deposition type hydroxyapatite scaffold;

[0043](2) Preparation of pre-crosslinked drug sustained-release hydrogel solution;

[0044](3) Use gelatin to seal the holes in the lower layer of the hydroxyapatite scaffold;

[0045](4) Inject the pre-crosslinked drug sustained-release hydrogel solution in step (2) on the upper layer of the hydroxyapatite scaffold in step (3) by means of a mold, and cross-link under ultraviolet light;

[0046](5) Wash the hydrogel semi-embedded composite stent formed in step (4), and dissolve and remove the gelatin that seals the holes in the lower layer of the stent to obtain the drug sustained-release hydrogel semi-embedded composite stent.

[0047]Further, in the step (1), the preparation method of the alendronate sodium deposition type hydroxyapatite scaffold includes the follo...

Embodiment 2

[0065]The difference between this example and Example 1 is that the preparation of the alendronate sodium deposition type hydroxyapatite scaffold is as follows: The preparation is as follows: by weight, hydroxyapatite powder and dispersant PAA-NH4 ( The solid content is soluble in water / glycerin (w / w, 7 / 3) and NH is used3·H2O adjust the pH to 9.50 to prepare a mixture, the added concentration of the hydroxyapatite powder is 45% by weight, and the addition amount of the dispersant PAA-NH4 is 1.5% of the mass of the hydroxyapatite powder; put the mixture into a ball mill pot Mid-grind for 12 h, then add hydroxypropyl methyl cellulose and n-octanol to the ball mill to obtain a slurry with appropriate viscosity. A cylindrical hydroxyapatite three-dimensional scaffold with 60% scaffold porosity was obtained by 3D printing technology, and the printed scaffold was sintered at a high temperature of 1110°C for 3 hours. The bracket is printed with a 30° oblique angle, the bracket radius is 6 ...

Embodiment 3

[0068]The difference between this embodiment and Embodiment 1 is:

[0069]In the step (1), the preparation method of the alendronate sodium deposition type hydroxyapatite scaffold includes the following steps: soak the hydroxyapatite three-dimensional scaffold in alendronate sodium (ALN) solution (the The concentration of alendronate sodium solution is 10 μM), taken out for 12 h, and a low-density hydroxyapatite scaffold deposited by alendronate sodium was obtained. The alendronate sodium deposit was observed as fine needles by scanning electron microscope .

[0070]The rest of the content of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV radiation | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com