Cigarette filter tip absorbing material containing cellulose

A technology of adsorption materials and cigarette filters, which can be used in e-liquid filter elements, tobacco, applications, etc., and can solve the problems of slow reaction of hydrogen bond elements, easy adsorption saturation, poor selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

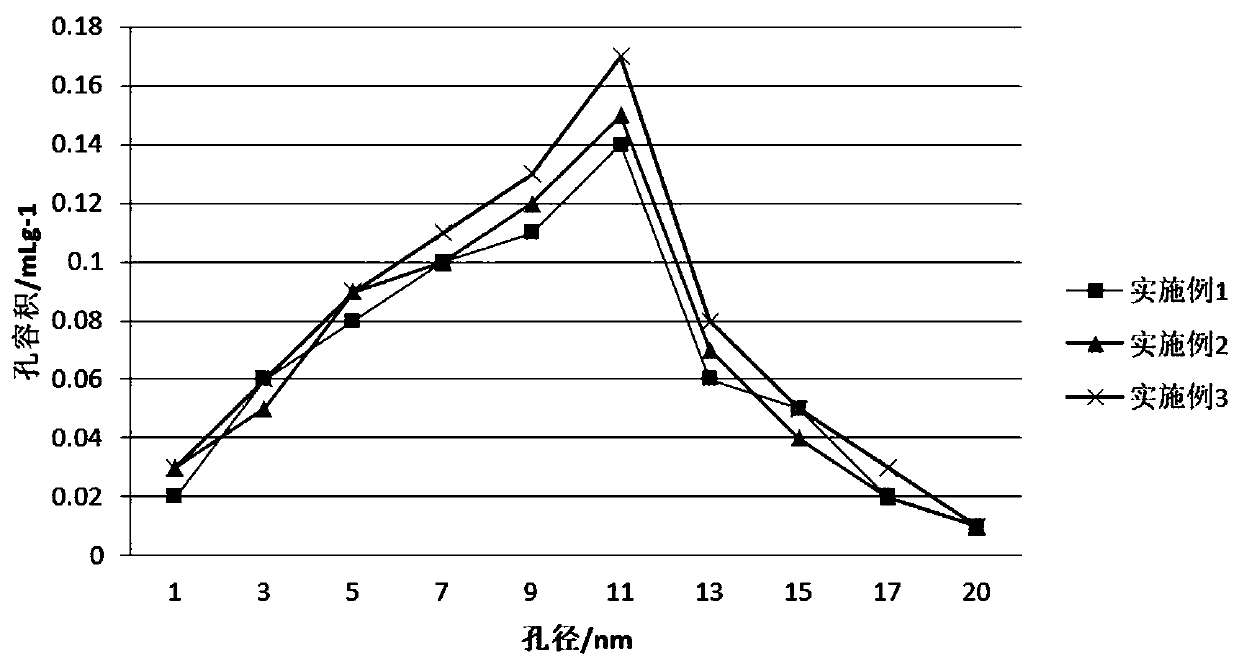

Embodiment 1

[0035] S1: Weigh a certain mass of bamboo pulp cellulose material with a polymerization degree of 500, heat it at 150°C for 20 minutes, and obtain a heat-activated bamboo pulp cellulose material; use distilled water as a solvent to prepare 6wt% sodium hydroxide, 3wt% The sodium hydroxide / urea mixture aqueous solution of urea content; According to mass ratio 5:1, the bamboo pulp cellulose material of thermal activation, lithium nitrate / diphenyl phthalate mixture are dispersed in sodium hydroxide / urea mixture aqueous solution, stir The bamboo pulp cellulose mixture is uniformly obtained; then the bamboo pulp cellulose mixture is frozen at -120° C. for 5 hours until completely frozen, dissolved at room temperature and stirred until completely dissolved to obtain a bamboo pulp cellulose mixture solution.

[0036] S2: Dispersing sodium alginate powder with a molecular weight of 100 kDa in distilled water, heating to 30° C. and blending to obtain a supernatant. According to the mass...

Embodiment 2

[0042]S1: Weigh a certain mass of bamboo pulp cellulose material with a polymerization degree of 500, heat it at 200°C for 40 minutes, and obtain a heat-activated bamboo pulp cellulose material; use distilled water as a solvent to prepare 7wt% sodium hydroxide, 4wt% The sodium hydroxide / urea mixture aqueous solution of urea content; According to mass ratio 8:1, the bamboo pulp cellulose material of thermal activation, lithium nitrate / diphenyl phthalate mixture are dispersed in sodium hydroxide / urea mixture aqueous solution, stir Uniformly obtain a bamboo pulp cellulose mixture; then place the bamboo pulp cellulose mixture at -50°C for 12 hours to freeze completely, dissolve at room temperature and stir until completely dissolved to obtain a bamboo pulp cellulose mixture solution

[0043] S2: Dispersing sodium alginate powder with a molecular weight of 300 kDa in distilled water, heating to 70° C. and blending to obtain a supernatant. According to the mass ratio, 1 part of sodi...

Embodiment 3

[0049] S1: Weigh a certain mass of bamboo pulp cellulose material with a polymerization degree of 500, heat it at 200°C for 60 minutes, and obtain a heat-activated bamboo pulp cellulose material; use distilled water as a solvent to prepare 8wt% sodium hydroxide, 5wt% The sodium hydroxide / urea mixture aqueous solution of urea content; According to mass ratio 10:1, the bamboo pulp cellulose material of thermal activation, lithium nitrate / diphenyl phthalate mixture are dispersed in sodium hydroxide / urea mixture aqueous solution, stir Uniformly obtain a bamboo pulp cellulose mixture; then place the bamboo pulp cellulose mixture at -20°C for 24 hours to freeze completely, dissolve at room temperature and stir until completely dissolved to obtain a bamboo pulp cellulose mixture solution

[0050] S2: Dispersing sodium alginate powder with a molecular weight of 200kDa in distilled water, heating to 70°C and blending to obtain a supernatant. According to the mass ratio, 1 part of sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com