Niobium pentoxide yolk structure nano material with controllable core volume and preparation method thereof

A technology of niobium pentoxide egg yolk and niobium pentoxide, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the negative effects of reducing the utilization rate of electrochemical active sites, material morphology and performance , material collapse or sintering, etc., to improve the conventional preparation method, simplify the preparation process, and enhance the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

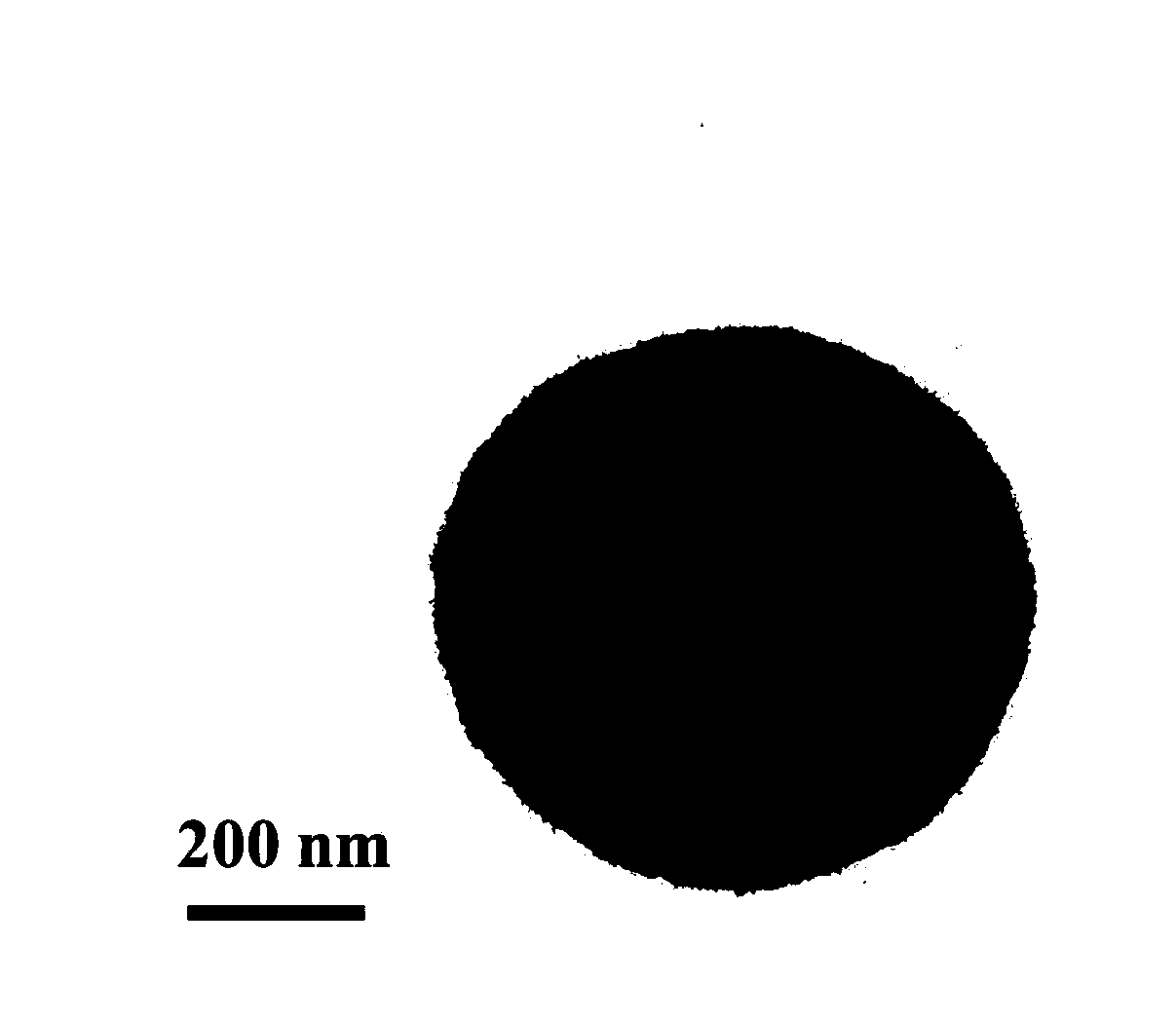

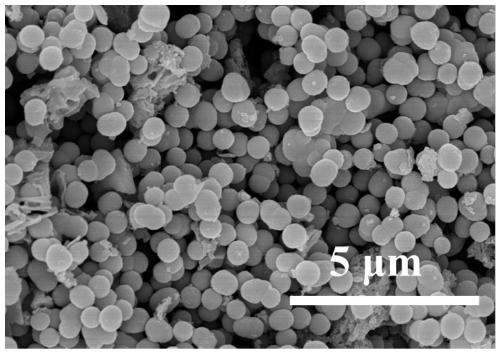

[0034] 1) Weigh 0.4 g of NbCl 5 Dissolve in 60 mL of isopropanol and add 0.4 g of TBA aqueous solution (10 wt%) under magnetic stirring. The above solution was transferred to a 100 mL autoclave and kept at 200 ºC for 24 h. After cooling to room temperature, the product was separated by centrifugation and washed several times, and dried at 60 ºC. Nb collected by centrifugation 2 o 5 TEM image see figure 1 as shown in figure 1 It can be seen that the diameter of the nanosphere is about 500 nm, and the surface is not smooth, which is helpful for the coating growth of dopamine hydrochloride.

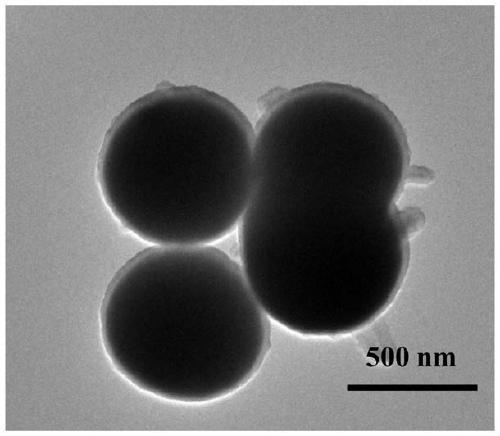

[0035] 2) Disperse niobium pentoxide nanospheres (80 mg) and dopamine hydrochloride (50 mg) in tris buffer solution under magnetic stirring. After stirring for 6 h, the centrifuged and dried samples were 2 Under protection, heat up to 500 ºC at a rate of 1 ºC / min and keep the temperature constant for 2 h. Samples were collected after cooling. The TEM image of the obtained product i...

Embodiment 2

[0042] 1) Weigh 0.4 g of NbCl 5 Dissolve in 60 mL of isopropanol and add 0.4 g of TBA aqueous solution (10 wt%) under magnetic stirring. The above solution was transferred to a 100 mL autoclave and kept at 200 ºC for 24 h. After cooling to room temperature, the product was separated by centrifugation and washed several times, and dried at 60 ºC.

[0043] 2) Disperse niobium pentoxide nanospheres (80 mg) and dopamine hydrochloride (50 mg) in tris under magnetic stirring. After stirring for 6 h, the centrifuged and dried samples were 2 Under protection, heat up to 500 ºC at a rate of 1 ºC / min and keep the temperature constant for 2 h. Samples were collected after cooling.

[0044] 3) Weigh 1 g of Nb 2 o 5 @NC nanospheres dispersed in 5.25 g hydrofluoric acid dilute solution (4 mol L -1 ) and stirred for 12h, the centrifuged and dried sample was annealed at 700 ºC for two hours, named as T-Nb 2 o 5 @NC-3. The TEM image of the obtained product is shown in Figure 5 as s...

Embodiment 3

[0046] 1) Weigh 0.4 g of NbCl 5 Dissolve in 60 mL of isopropanol and add 0.4 g of TBA aqueous solution (10 wt%) under magnetic stirring. The above solution was transferred to a 100 mL autoclave and kept at 200 ºC for 24 h. After cooling to room temperature, the product was separated by centrifugation and washed several times, and dried at 60 ºC.

[0047] 2) Disperse niobium pentoxide nanospheres (80 mg) and dopamine hydrochloride (50 mg) in tris under magnetic stirring. After stirring for 6 h, the centrifuged and dried samples were 2 Under protection, heat up to 500 ºC at a rate of 1 ºC / min and keep the temperature constant for 2 h. Samples were collected after cooling.

[0048] 3) Weigh 1 g of Nb 2 o 5 @NC nanospheres dispersed in 2.25 g hydrofluoric acid dilute solution (4 mol L -1 ) and stirred for 12h, the centrifuged and dried sample was annealed at 700 ºC for two hours, named as T-Nb 2 o 5 @NC-3. The TEM image of the obtained product is shown in Figure 6 as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com