Silicon-containing anti-caking granular macroelement formula fertilizer and preparation method thereof

A large amount of elements, anti-caking technology, applied in the direction of phosphate fertilizer, fertilization equipment, fertilizer mixture, etc., can solve the problems of low utilization rate of formula fertilizer, agglomeration of formula fertilizer, weak anti-caking ability, etc., to improve photosynthesis The effect of improving the ability of resistance to diseases and insect pests and the effect of improving the ability of anti-caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

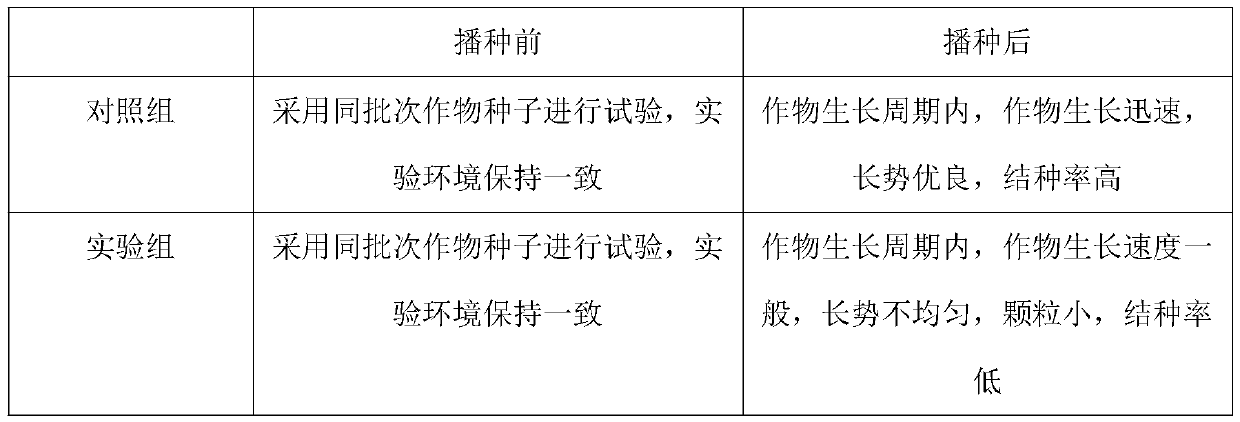

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of silicon-containing anti-caking granular macronutrient formula fertilizer proposed by the present invention comprises 25 parts of ammonium chloride, 5 parts of ammonium nitrate, 10 parts of urea, 10 parts of amide nitric acid, 30 parts of diamine phosphate, and 10 parts of potassium dihydrogen phosphate. 30 parts of superphosphate, 5 parts of potassium chloride, 15 parts of silicon magnesium potassium fertilizer, 5 parts of sodium silicate, 5 parts of dolomite, 5 parts of alkaline slag, and 5 parts of surfactant.

[0023] A kind of preparation method of silicon-containing anti-caking granular macronutrient formula fertilizer proposed by the present invention comprises the following steps:

[0024] S1, mix the raw materials ammonium chloride, ammonium nitrate, urea, amide nitrate, diamine phosphate, potassium dihydrogen phosphate, superphosphate, potassium chloride, silicon magnesium potassium fertilizer, and sodium silicate according to the proportioning ratio; ...

Embodiment 2

[0030] A silicon-containing anti-caking granular macronutrient formula fertilizer proposed by the present invention comprises 30 parts of ammonium chloride, 10 parts of ammonium nitrate, 15 parts of urea, 15 parts of amide nitric acid, 35 parts of diamine phosphate, and 15 parts of potassium dihydrogen phosphate. 35 parts of calcium superphosphate, 7 parts of potassium chloride, 20 parts of silicon magnesium potassium fertilizer, 7 parts of sodium silicate, 6 parts of dolomite, 6 parts of alkaline slag, and 6 parts of surfactant.

[0031] A kind of preparation method of silicon-containing anti-caking granular macronutrient formula fertilizer proposed by the present invention comprises the following steps:

[0032] S1, mix raw materials such as ammonium chloride, ammonium nitrate, urea, amide nitrate, diamine phosphate, potassium dihydrogen phosphate, superphosphate, potassium chloride, silicon magnesium potassium fertilizer, and sodium silicate according to the proportioning ra...

Embodiment 3

[0038] A silicon-containing anti-caking granular macronutrient formula fertilizer proposed by the present invention comprises 35 parts of ammonium chloride, 12 parts of ammonium nitrate, 18 parts of urea, 25 parts of amide nitric acid, 38 parts of diamine phosphate, and 18 parts of potassium dihydrogen phosphate. 38 parts of calcium superphosphate, 12 parts of potassium chloride, 18 parts of silicon magnesium potassium fertilizer, 7 parts of sodium silicate, 8 parts of dolomite, 9 parts of alkaline slag, and 8 parts of surfactant.

[0039] A kind of preparation method of silicon-containing anti-caking granular macronutrient formula fertilizer proposed by the present invention comprises the following steps:

[0040] S1, mix raw materials such as ammonium chloride, ammonium nitrate, urea, amide nitrate, diamine phosphate, potassium dihydrogen phosphate, superphosphate, potassium chloride, silicon magnesium potassium fertilizer, and sodium silicate according to the proportioning r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com