Biodiesel preparation system suitable for kitchen oil

A biodiesel, kitchen technology, applied in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve problems such as many side reactions, large demand for methanol, easy-to-corrode equipment, etc., to improve purity and quality, electrochemical The effect of high stability and high electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

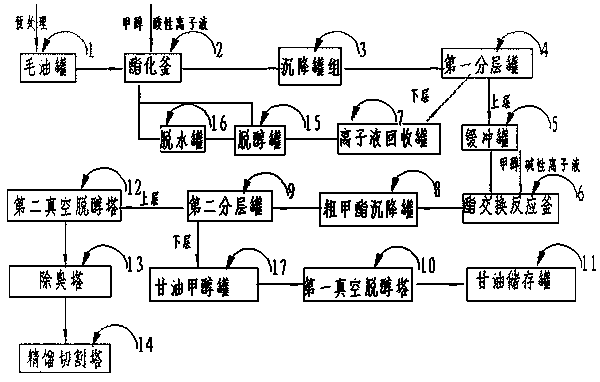

[0023] The present invention will be further described in detail below in conjunction with the drawings.

[0024] The reference signs in the drawings of the specification include: crude oil tank 1, esterification tank 2, settling tank group 3, first stratification tank 4, buffer tank 5, transesterification reactor 6, ionic liquid recovery tank 7, crude armour Ester sedimentation tank 8, second stratification tank 9, first vacuum dealcoholization tower 10, glycerin storage tank 11, second vacuum dealcoholization tower 12, deodorization tower 13, rectification cutting tower 14, dealcoholization tank 15, dehydration Tank 16, glycerin methanol tank 17.

[0025] A biodiesel preparation system suitable for cooking oil in this specific embodiment, such as figure 1 As shown, it includes a crude oil tank for receiving water and impurities removed by the pretreatment system 1, an esterification kettle connected to the outlet of the crude oil tank 1 and an esterification kettle 2 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com