A low-temperature preparation method of α-phase low-sodium alumina powder

A technology of sodium alumina and alumina, which is applied in the field of alumina powder preparation, can solve the problems of irregular alumina grain shape, high alumina calcination temperature, and high impurity content, achieve uniform particle size, and reduce sintering temperature , the effect of low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A low-temperature preparation method of α-phase low-sodium alumina powder, comprising the following steps:

[0038] (a) grinding a mixture of industrial alumina and water to obtain a refined alumina precursor slurry;

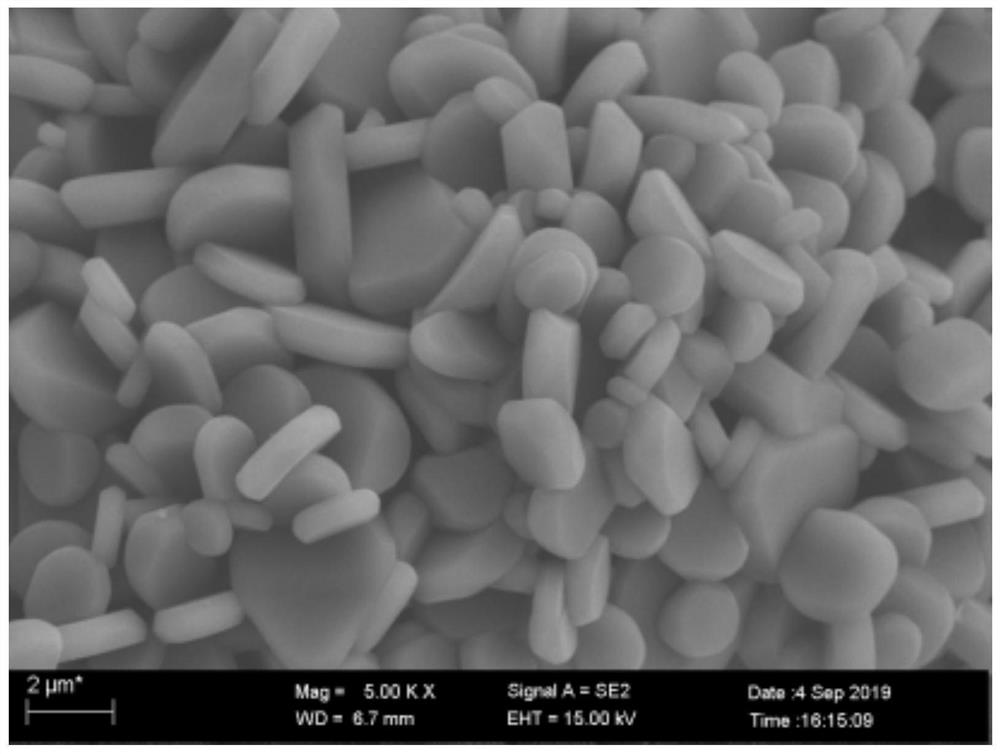

[0039] The present invention uses industrial alumina as raw material, and prepares low-sodium alumina powder (Na 2 O content is 0.01-0.02%). The method has the advantages of wide source of raw materials, simple production process, low production cost, low calcining temperature, no pollution to the environment and the like. With the help of ball milling and ultrasonic external force, the size of industrial alumina raw materials is reduced, the contact area between industrial alumina and liquid is increased, and a force is formed on the surface of industrial alumina particles, so that impurities such as sodium oxide are stripped from the surface of industrial alumina.

[0040] Wherein, in some preferred embodiments, the water is deionized water, and the m...

Embodiment 1

[0062] The preparation method of low-temperature α-phase low-sodium alumina powder of the present invention comprises the following steps:

[0063] (1) Mix industrial alumina and deionized water, the amount of deionized water added is equivalent to twice the weight of industrial alumina, make an alumina slurry with a concentration of 30%, and then put it into a planetary ball mill for ball milling . The medium of ball milling is zirconia ball, the diameter of zirconia ball is 0.5mm, and the grinding time is 3h.

[0064] (2) Add composite additives to the alumina precursor slurry prepared in step (1), the addition of hydrochloric acid in the composite additives is 0.03% of the weight of alumina, and the addition of aluminum fluoride is 0.1% of the weight of alumina , and prepare alumina precursor slurry.

[0065] (3) Put the alumina precursor slurry prepared in step (2) into a 35°C water bath, and stir for 60 minutes with a magnetic stirrer, the rotating speed of the magnetic...

Embodiment 2

[0073] The preparation method of low-temperature α-phase low-sodium alumina powder of the present invention comprises the following steps:

[0074] (1) Mix industrial alumina and deionized water, the amount of deionized water added is equivalent to twice the weight of industrial alumina, make an alumina slurry with a concentration of 30%, and then put it into a planetary ball mill for ball milling . The medium of ball milling is zirconia ball, the diameter of zirconia ball is 1mm, and the grinding time is 5h.

[0075] (2) Add composite additives to the alumina precursor slurry prepared in step (1), the addition of hydrochloric acid in the composite additives is 0.08% of the weight of alumina, and the addition of aluminum fluoride is 0.2% of the weight of alumina , and prepare alumina precursor slurry.

[0076] (3) Put the alumina precursor slurry prepared in step (2) into a 50°C water bath, and stir for 60 minutes with a magnetic stirrer, the rotating speed of the magnetic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com