Electromagnetic integrated MEMS scanning micromirror

A scanning micromirror, electromagnetic technology, applied in optical components, optics, instruments, etc., can solve the problems of unfavorable development of spectrometer portability, small contact area at the connection, poor structural stability, etc., to save coil materials, reduce Package volume, the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

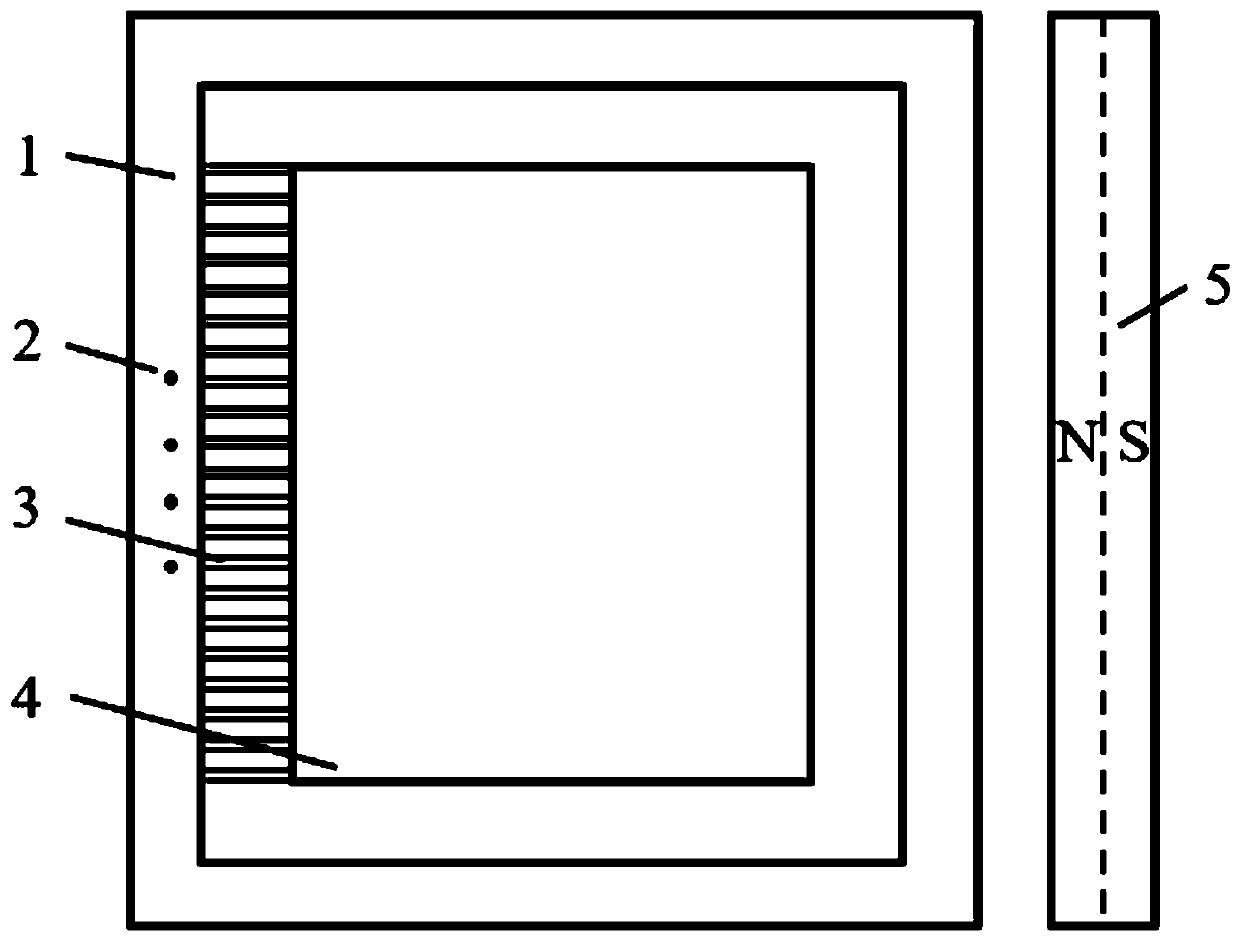

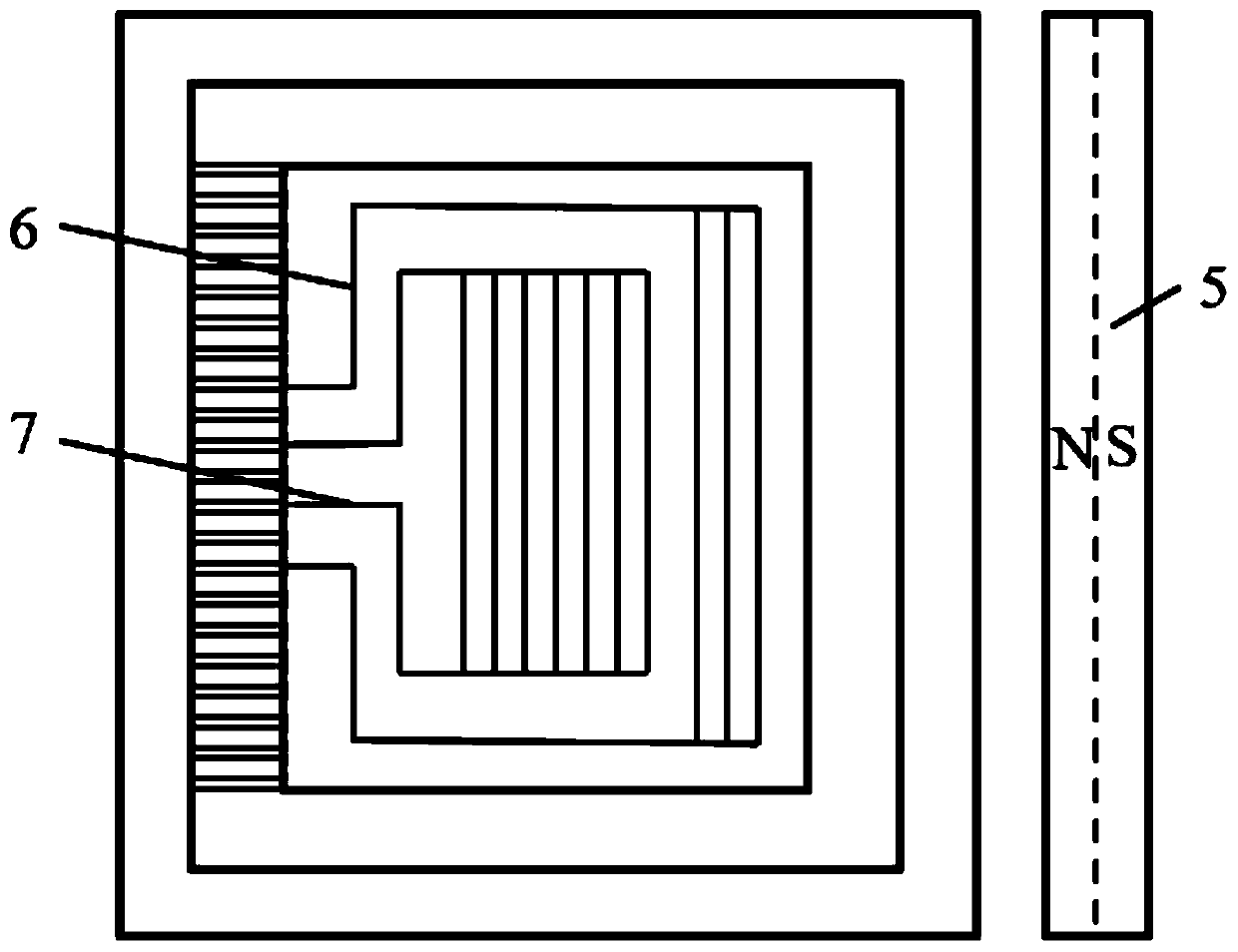

[0028] Such as figure 1 and figure 2 As shown, the present embodiment provides an electromagnetic integrated MEMS scanning micromirror, which is integrated and manufactured through MEMS processing technology, including a fixed frame 1 and a drive coil 7 and an angle sensing coil 6 integrated on the inside of the fixed frame 1 and integrated on the back. The monotectic silicon-based micromirror plate 4 is connected between the fixed frame 1 and the partial crystal silicon-based micromirror plate 4 with a connecting plate 3 extending along one side of the partial crystal silicon-based micromirror plate 4 .

[0029] Specifically, the front and back of the monotectic silicon-based micromirror plate 4 are rectangular, and the surface area is 7*6mm 2 , the thickness is 0.4mm. The fixed frame 1 provides freedom constraints and supports for the work of the scanning micromirror. The size of the fixed frame 1 is designed corresponding to the size of the monomorphic silicon-based micr...

Embodiment 2

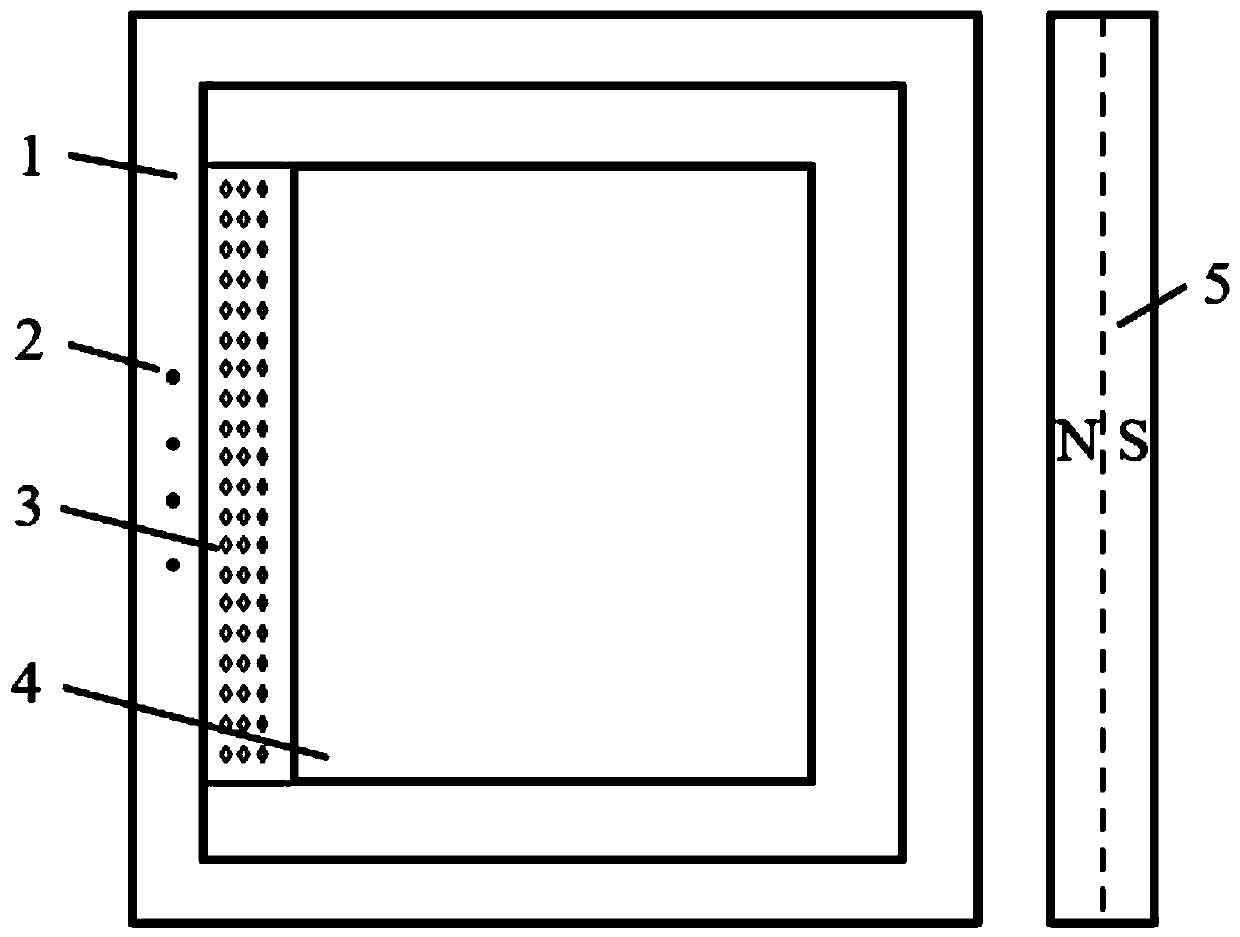

[0036] Such as image 3 As shown, the difference between the second embodiment and the first embodiment lies in the specific structure of the connecting plate 3 . In the second embodiment, the connecting plate 3 is provided with holes arranged in a grid to improve the bending deflection performance of the connecting plate 3 .

Embodiment 3

[0038] Such as Figure 4 As shown, the difference between the third embodiment and the first embodiment is that the specific structure of the connecting plate 3 is different. In the third embodiment, the connecting plate 3 is provided with a plurality of parallel equidistant rectangular grooves to improve the bending deflection performance of the connecting plate 3 .

[0039]As an improvement of the above-mentioned embodiment, the drive coil 7 is stacked with multiple layers, and the driving operation of the scanning micromirror is related to the magnitude of the drive current and the strength of the magnetic field. The increase in the number of layers of the drive coil 7 can effectively reduce the resistance of the drive coil 7, and accordingly it will last forever. The volume of the magnet 5 can be reduced, thereby reducing the package volume of the scanning micromirror. In order to enhance the signal output of the angle sensing coil 6 , the angle sensing coil 6 may also be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com