Preparation method of difunctional molybdenum-doped cobalt sulfide/nitrogen-carbon array electrode

A technology of array electrodes and cobalt sulfide, which is applied to battery electrodes, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve the problems of limited commercial application of earth reserves, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

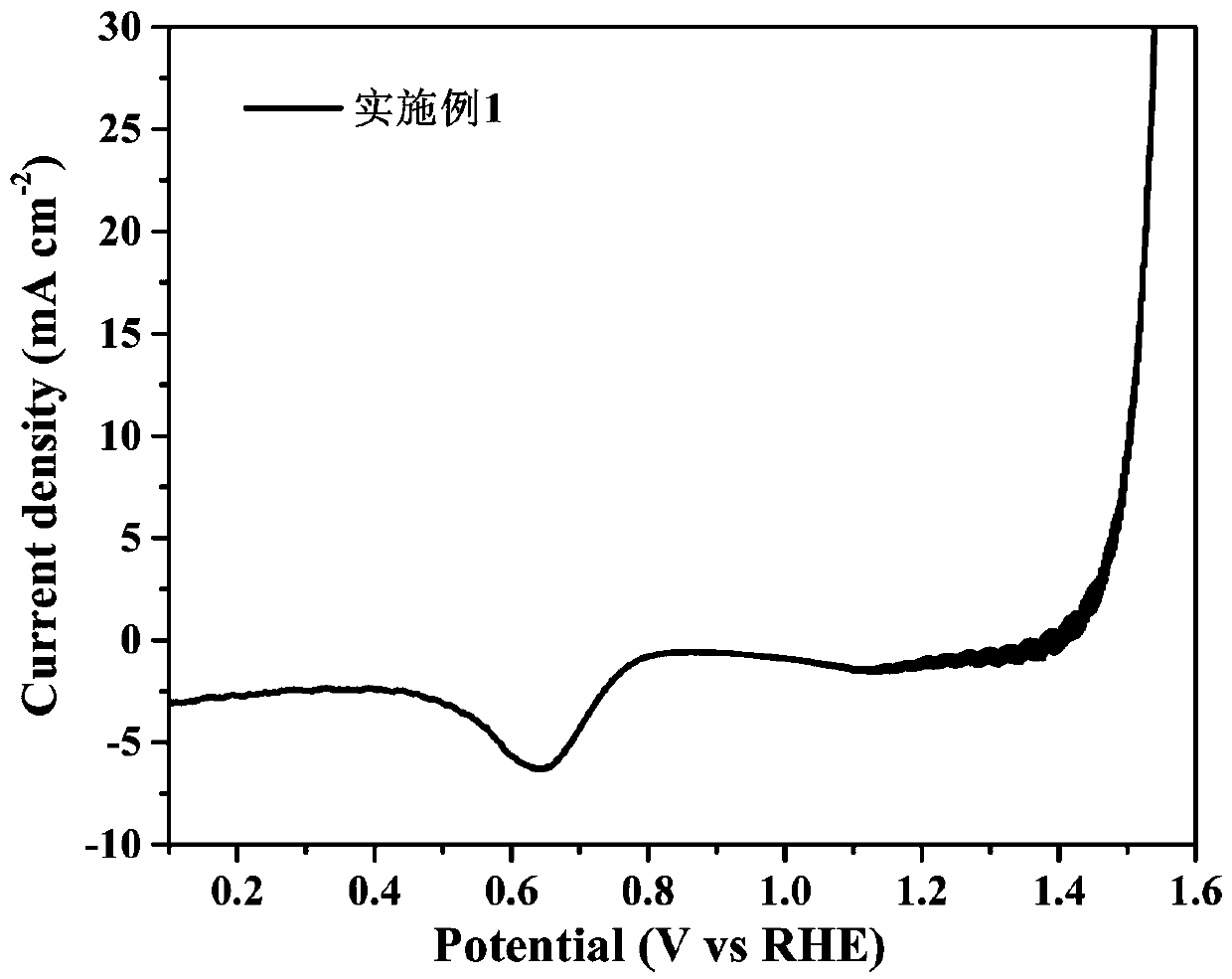

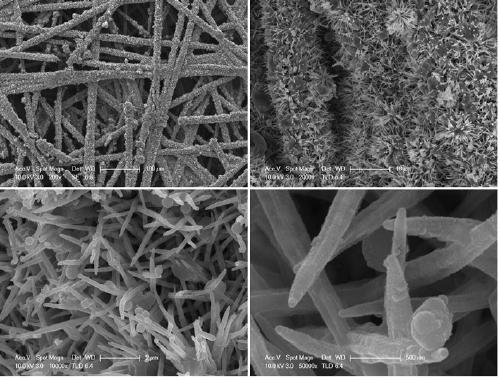

Embodiment 1

[0025] CoCl 2 ∙6H 2 O and urea were dissolved in 40 mL of deionized water at room temperature, in which CoCl 2 The concentration of urea was 0.15 M, and the mass fraction of urea was 6.25 wt.%. After immersing the hydrophilic carbon paper in the solution, it was incubated at 90°C for 2 h. After natural cooling to room temperature, the carbon paper was taken out and rinsed with deionized water. Three times, dry and set aside. Soak the above-mentioned carbon paper grown with basic cobalt salt arrays in 50 mL of Tris base with a concentration of 0.01 M and a pH of 8.5, add 0.01 g of dopamine, stir at room temperature for 24 h, and rinse the sample three times with deionized water dry. Dissolve molybdenum chloride in ethanol solution, stir to dissolve, and obtain 400 mM molybdenum chloride ethanol solution. The above-mentioned carbon paper on which the basic cobalt salt array@PDA array was grown was soaked in the molybdenum chloride solution for about 1 min at room temperature...

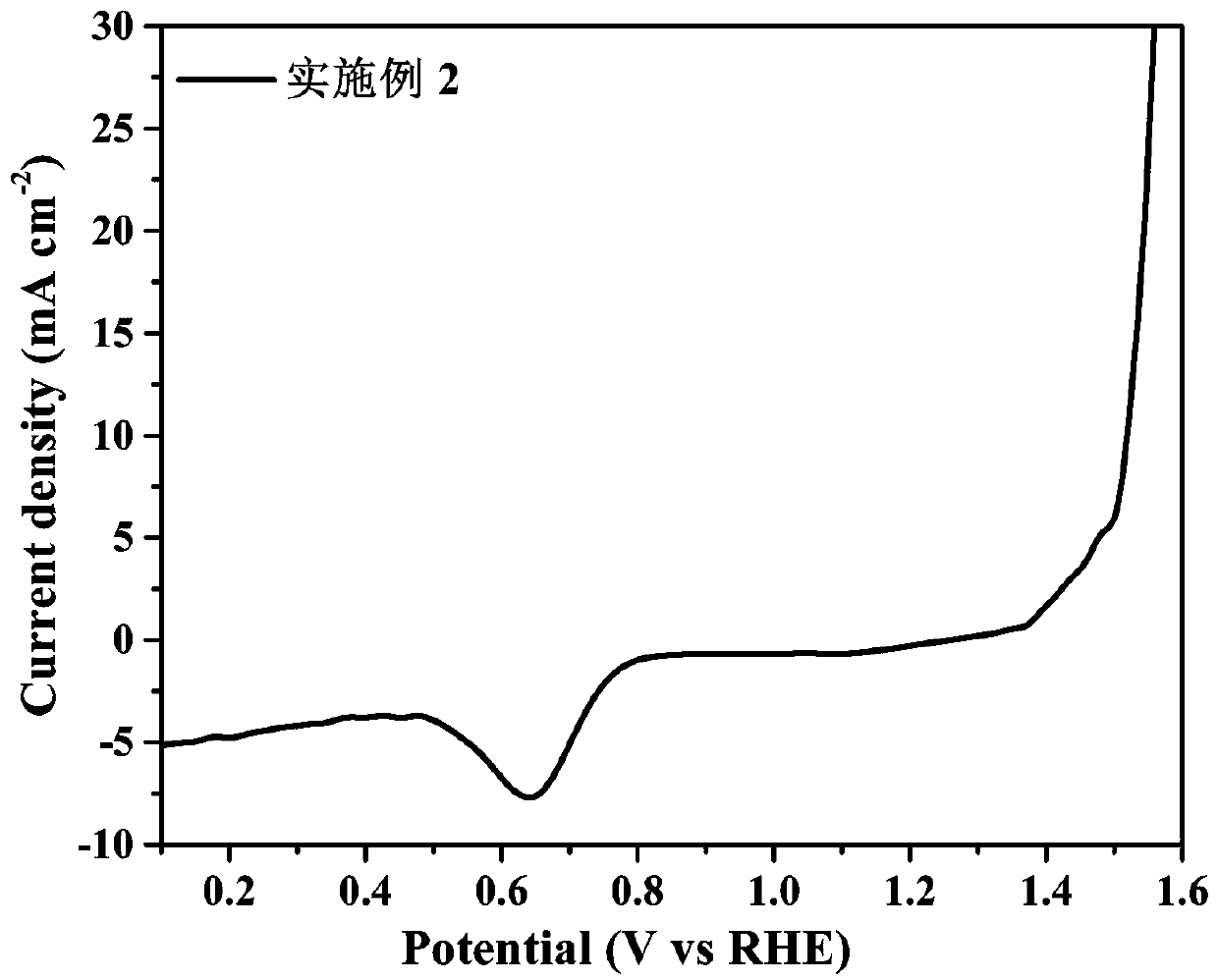

Embodiment 2

[0028] CoCl 2 ∙6H 2 O and urea were dissolved in 40 mL of deionized water at room temperature, in which CoCl 2 The concentration of urea was 0.15 M, and the mass fraction of urea was 6.25 wt.%. After immersing the hydrophilic carbon paper in the solution, it was incubated at 90°C for 2 h. After natural cooling to room temperature, the carbon paper was taken out and rinsed with deionized water. Three times, dry and set aside. Soak the carbon paper on which the basic cobalt salt array was grown above in 50 mL of Tris base with a concentration of 0.01 M and a pH of 8.5, add 0.02 g of dopamine, stir at room temperature for 24 h, and rinse the sample three times with deionized water dry. Dissolve molybdenum chloride in ethanol solution, stir to dissolve, and obtain 400 mM molybdenum chloride ethanol solution. The above-mentioned carbon paper on which the basic cobalt salt array@PDA array was grown was soaked in the molybdenum chloride solution for about 1 min at room temperatur...

Embodiment 3

[0032] CoCl 2 ∙6H 2 O and urea were dissolved in 40 mL of deionized water at room temperature, in which CoCl 2 The concentration of urea was 0.15 M, and the mass fraction of urea was 6.25 wt.%. After immersing the hydrophilic carbon paper in the solution, it was incubated at 90°C for 2 h. After natural cooling to room temperature, the carbon paper was taken out and rinsed with deionized water. Three times, dry and set aside. The carbon paper with the basic cobalt salt array grown was placed in the air at 400°C for 0.5 h to obtain the carbon paper substrate with the cobalt oxide array grown, which was taken out after natural cooling for use. Soak the above-mentioned carbon paper with cobalt oxide arrays grown in 50 mL of Tris base with a concentration of 0.01 M and a pH of 8.5, add 0.02 g of dopamine, stir at room temperature for 24 h, rinse the sample three times with deionized water and then dry it. Dissolve molybdenum chloride in ethanol solution, stir to dissolve, and ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com