Reticular polymer, preparation method thereof, semi-interpenetrating network polymer electrolyte and polymer lithium battery

A semi-interpenetrating network and polymer technology, applied in the field of semi-interpenetrating network polymer electrolytes and polymer lithium batteries, can solve the problems of low ionic conductivity and large interface impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides the preparation method of the reticulated polymer described in the above scheme, comprising the following steps:

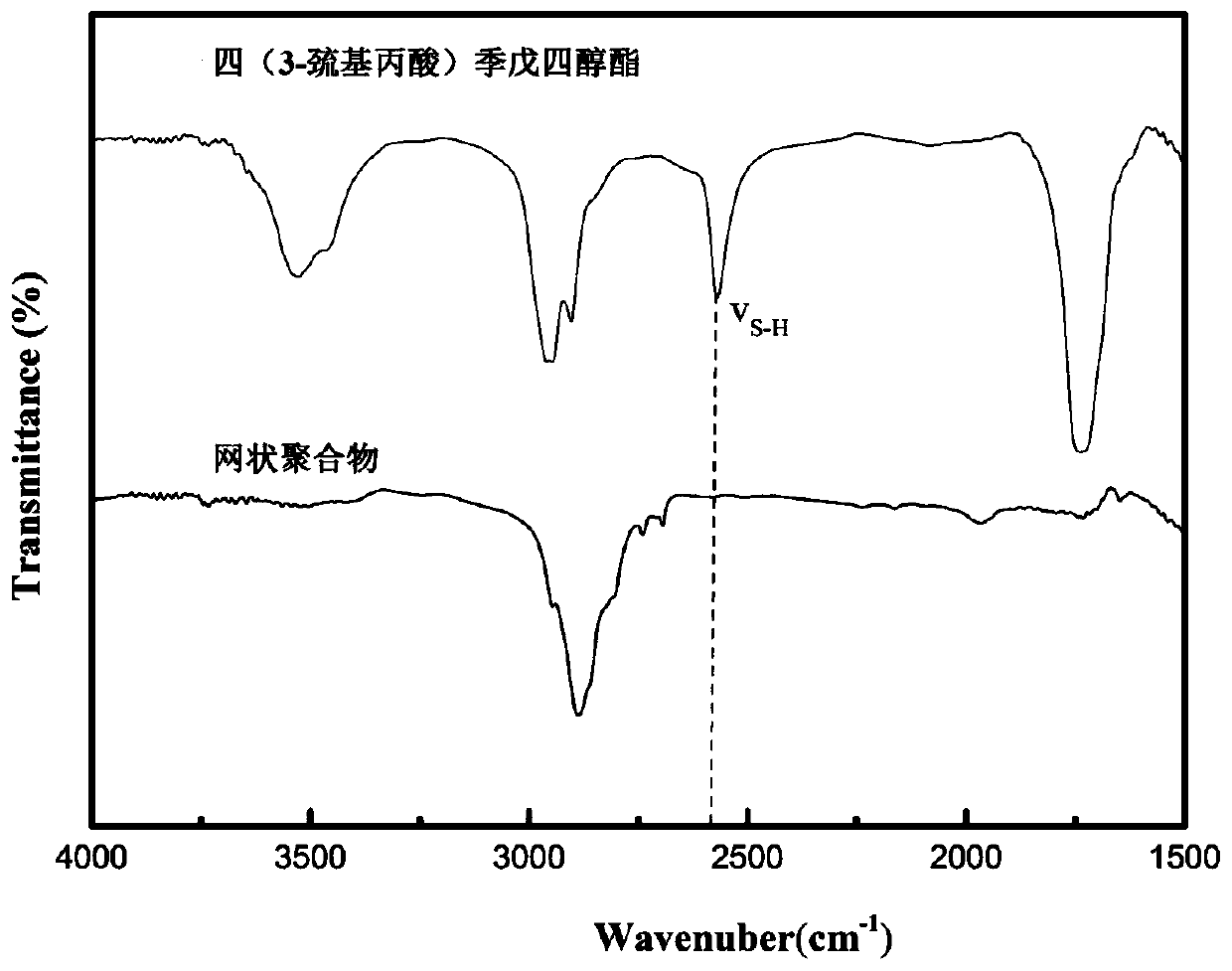

[0042] Polyethylene glycol di-p-toluenesulfonate, polyethylene glycol monomethyl ether-p-toluenesulfonate and tetrakis (3-mercaptopropionic acid) pentaerythritol ester are carried out polymerization reaction in the organic solvent of ethoxide to obtain the net shape polymer.

[0043] The present invention has no special requirements on the source of polyethylene glycol di-p-toluenesulfonate, and can adopt commercially available products well known to those skilled in the art or prepare by themselves. When the polyethylene glycol di-p-toluenesulfonate is prepared by itself, the preparation method preferably includes the following steps:

[0044] Polyethylene glycol and p-toluenesulfonyl chloride are dissolved in an organic solvent, and a substitution reaction is carried out under the action of NaOH to obtain polyethylene glyco...

Embodiment 1

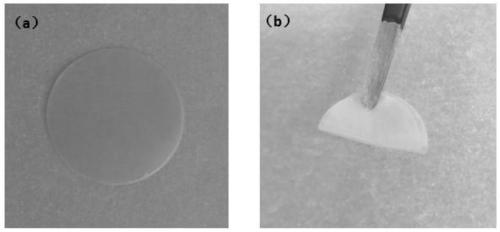

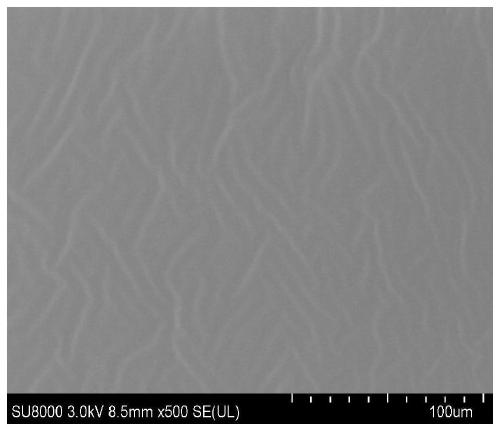

[0068] The preparation of semi-interpenetrating network polymer electrolyte, the steps are as follows:

[0069] (1) Dissolve 10 g of polyethylene glycol with a molecular weight of 4000 g / mol and 1.24 g of p-toluenesulfonyl chloride in tetrahydrofuran, add 0.4 g of NaOH and stir at room temperature for 24 hours to obtain polyethylene glycol di-p-toluenesulfonate; Dissolve 25g of polyethylene glycol monomethyl ether with a molecular weight of 5000g / mol and 1.24g of p-toluenesulfonyl chloride in tetrahydrofuran, add 0.4g of NaOH and stir at room temperature for 20h to obtain polyethylene glycol monomethyl ether p-toluenesulfonate ;

[0070] (2) 2.154g polyethylene glycol di-p-toluenesulfonate in step (1), 5.154g polyethylene glycol monomethyl ether p-toluenesulfonate and 0.244g tetrakis (3-mercapto propionate) pentaerythritol ester Dissolve in ethanol, add 1.5g of sodium ethylate and polymerize at 60°C for 72 hours to obtain a network polymer;

[0071] (3) Dissolve 0.26g of pol...

Embodiment 2

[0079] The preparation of semi-interpenetrating network polymer electrolyte, the steps are as follows:

[0080] (1) Dissolve 25 g of polyethylene glycol with a molecular weight of 10000 g / mol and 1.24 g of p-toluenesulfonyl chloride in tetrahydrofuran, add 0.4 g of NaOH and stir at room temperature for 24 hours to obtain polyethylene glycol di-p-toluenesulfonate; Polyethylene glycol monomethyl ether with a molecular weight of 5000 g / mol and 1.24 g of p-toluenesulfonyl chloride were dissolved in tetrahydrofuran, and 0.4 g of NaOH was added and stirred at room temperature for 20 h to obtain polyethylene glycol monomethyl ether p-toluenesulfonate;

[0081] (2) 5.154g polyethylene glycol di-p-toluenesulfonate in step (1), 5.154g polyethylene glycol monomethyl ether p-toluenesulfonate and 0.244g tetrakis (3-mercaptopropionic acid) pentaerythritol ester Dissolve in ethanol, add 1.5g of sodium ethylate and react at 60°C for 72 hours to obtain a network polymer;

[0082] (3) Dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com