Composite polishing solution for blue glass optical filter, and preparation method thereof

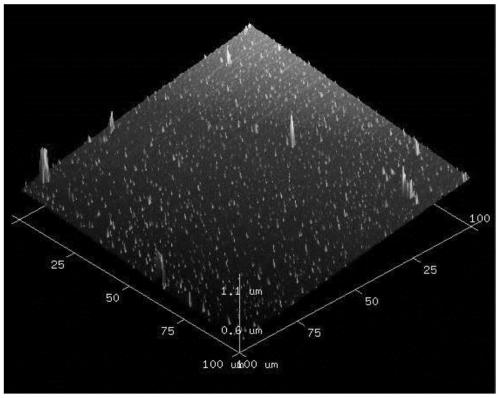

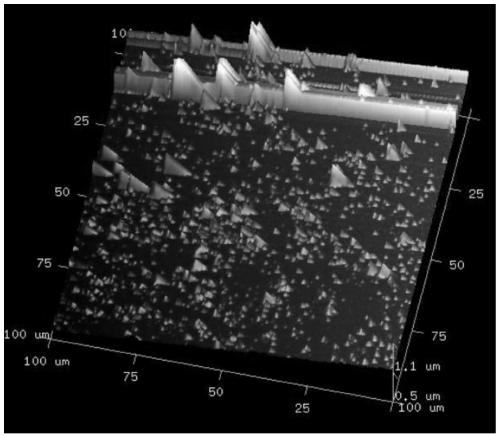

A composite polishing and optical filter technology, applied in polishing compositions containing abrasives, etc., can solve the problems of expensive machine investment, time-consuming and material-consuming, low pass-through rate of blue glass processing, etc., to achieve no surface defects, Improve polishing efficiency and improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0034] The invention provides a compound polishing liquid for blue glass filter, the compound polishing liquid comprises aluminum hydroxide, zirconium hydroxide and silica sol, liquid caustic soda, surface active agent, defoaming agent and water.

[0035] The present invention also provides a kind of preparation method of the composite polishing fluid that is used for blue glass filter, comprises the steps:

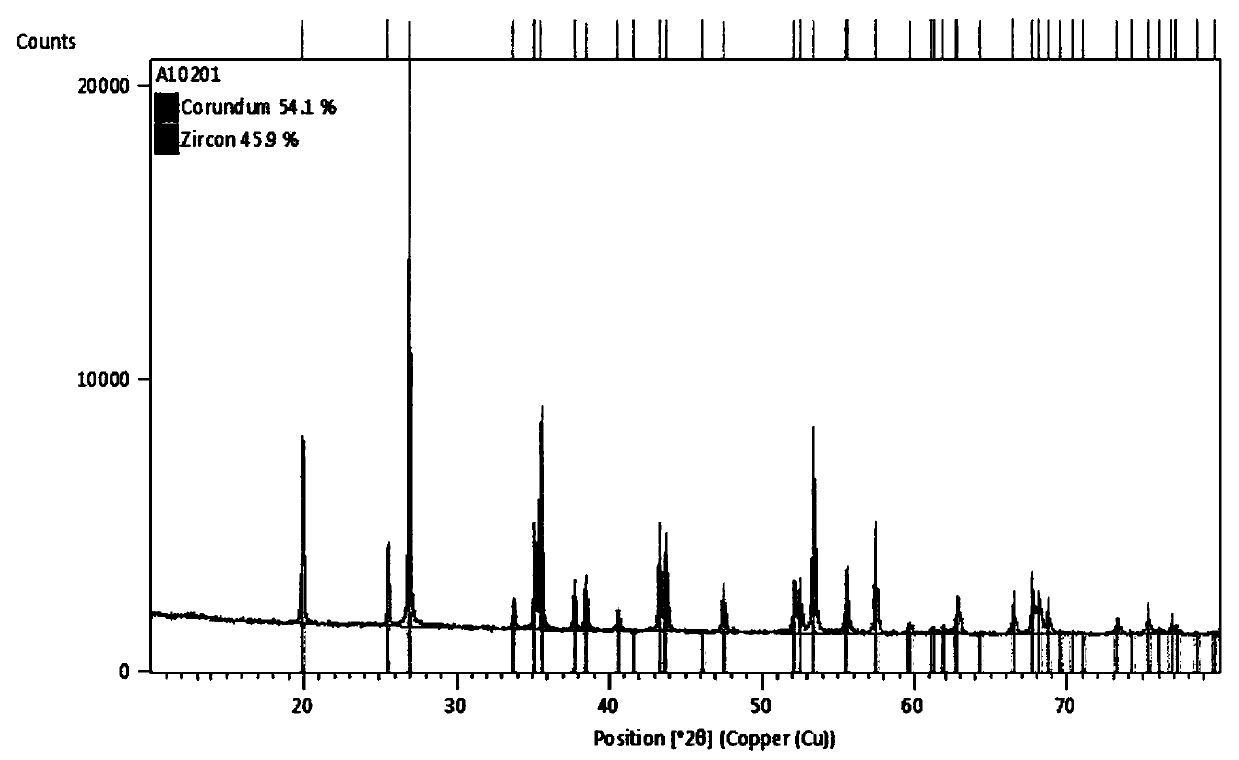

[0036] (1) Adding mass ratio to the reactor is 5% deionized water, adding aluminum hydroxide (γ-Al(OH) 3 Or γ-AlOOH or α-Al(OH) 3 ), after stirring for 20min, control the specific gravity between 1.1-1.2, slowly add zirconium hydroxide with a mass ratio of 30%, continue to stir for 20min, add a mass ratio of 20% silica sol, and add a mass ratio of 5% carboxylate Methylc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com