Method for repairing Cd or Pb contaminated soil by combining coal gasification slag with ryegrass

A technology for coal gasification slag and polluted soil, applied in the field of soil pollution control, can solve the problems of low biomass absorption by plants, short plant growth, and long time for phytoremediation of soil pollution, so as to increase biomass, improve adsorption capacity, and improve root the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment includes the following steps:

[0041] Step 1. Air-dry the soil and pass it through a 100-mesh sieve to remove large impurities such as gravel, animal and plant residues, and measure the soil's pH, organic matter, total nitrogen, total phosphorus, total potassium, and cation exchange capacity to determine soil performance parameters ;

[0042] Step 2. According to the mass ratio of 1:4, the coal gasification slag with a particle size of 150 mesh to 200 mesh is added to the sieved soil in step 1 and mixed evenly to obtain a mixed soil;

[0043] Step three, 200mL concentration is the Cd(Cl) of 1.25g / L 2 Add the solution to 10kg of the mixed soil obtained in step 2 and stir evenly, then seal it with a plastic film, and store it in a dark place for 3 months to obtain Cd-contaminated soil; the Cd concentration in the Cd-contaminated soil is 25mg / kg;

[0044] Step 4. Put the Cd-contaminated soil obtained in Step 3 into a plastic flowerpot with a height of 30...

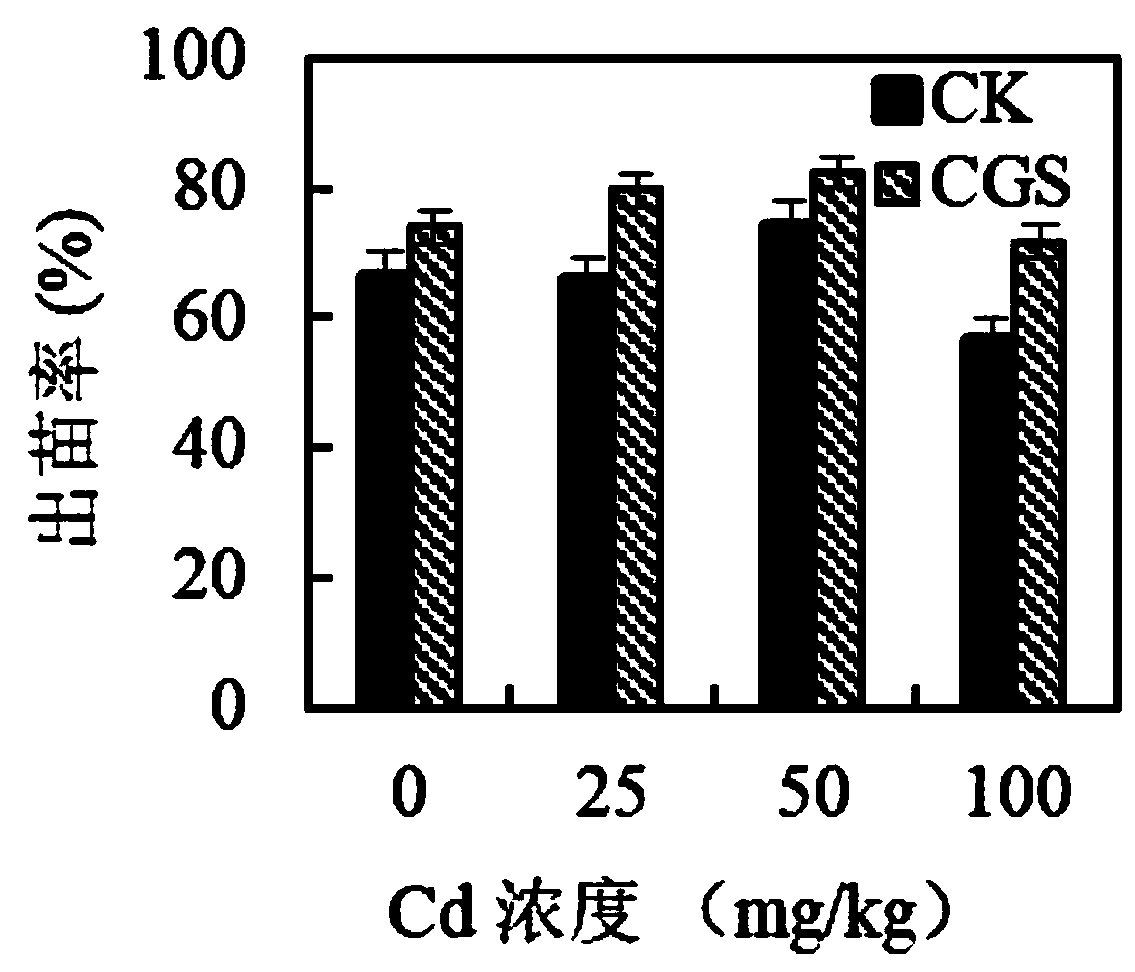

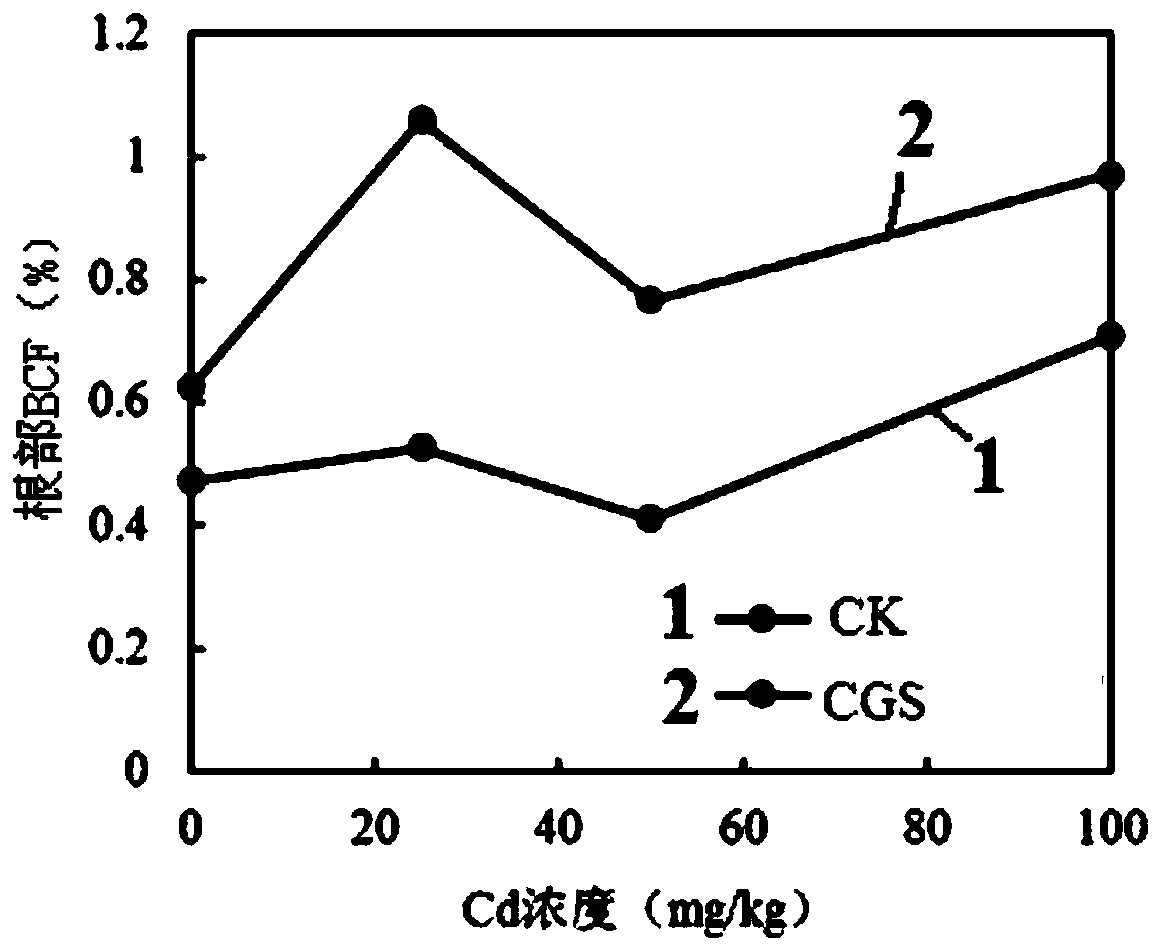

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is: in step 3, Cd(Cl) 2 The mass concentration of the solution is 2.50g / L, and the Cd concentration in the Cd-contaminated soil is 50mg / kg.

[0048] In addition, the ryegrass obtained under the same process conditions as in Example 2 but without adding coalification gas slag was used as the control group (CK) of Example 2, and the ryegrass obtained in Example 2 was used as the sample group (CGS).

Embodiment 3

[0050] The difference between this embodiment and embodiment 1 is: in step 3, Cd(Cl) 2 The mass concentration of the solution is 5.0g / L, and the Cd concentration in the Cd-polluted soil is 100mg / kg.

[0051] In addition, the ryegrass obtained under the same process conditions as in Example 3 but without adding coalification gas slag was used as the control group (CK) of Example 3, and the ryegrass obtained in Example 3 was used as the sample group (CGS).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com