Method for rapidly preparing high-aluminum aerogel composite material based on aluminum isopropoxide

A technology of aluminum isopropoxide and composite materials, which is applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of high brittleness, low strength, difficult forming, etc., to improve the reaction rate and efficiency, improve the reaction efficiency, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of silica sol

[0029] Take ethyl orthosilicate: take 180L ethyl orthosilicate, 45L water, 790L ethanol, adjust the pH to 5.5 with 10% hydrochloric acid solution, stir for 30 minutes, and obtain a silica sol with a concentration of 0.8mol / L, and let it stand for later use .

[0030] (2) Preparation of aluminum sol

[0031] First, after sieving 204kg of aluminum isopropoxide with a 60-mesh sieve, add it to a 2000L jacketed reaction tank filled with 400L of ethanol and 39L of ethyl acetoacetate, stir for 10 minutes, and fully soak and wet it. Open the jacket inlet valve of the jacketed reaction tank, control the inlet temperature of the heating medium to 90°C, and control the outlet temperature to 80°C, add 700L of boiling water to the reaction tank, and continue stirring for about 10 minutes until there is no foam. Then, add 300L ethanol to 300L concentration of 6% nitric acid aqueous solution, after stirring evenly, slowly add in the jacket reaction ta...

Embodiment 2

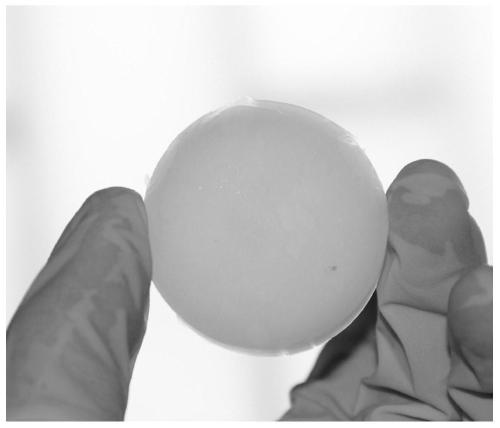

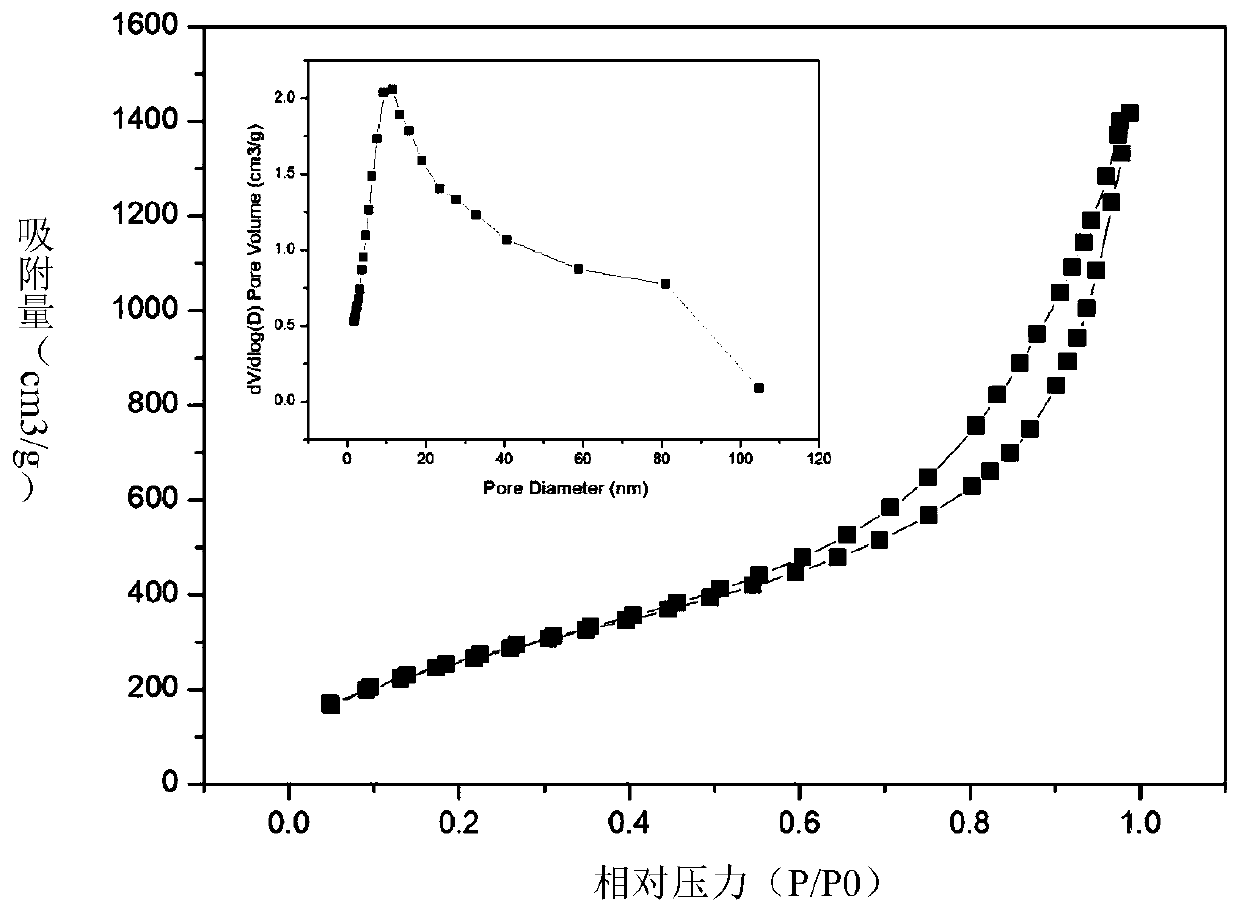

[0036] Take 10mL of silica sol and 50mL of aluminum sol in Example 1, stir rapidly after mixing for 1min, and obtain a transparent gel after standing for 8min, and obtain a high-alumina aerogel after supercritical drying. figure 2 Shown, test its specific surface area to be 380m2 / g, average pore diameter 11nm, pore volume 1.7cm3 / g, density 0.87g / cm3.

[0037] as in the accompanying drawings image 3 As shown, the airgel obtained in Example 2 has narrower pore size, more uniform pore distribution, and the formed polycrystalline boehmite has a more complete structure and better temperature resistance. It can be widely used in thermal protection in defense industry fields such as high-sonic aircraft and thermal batteries, as well as heat preservation and energy saving in high-temperature industrial fields such as metallurgy and ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com