Fully synthetic cutting fluid for sapphire processing and preparation method thereof

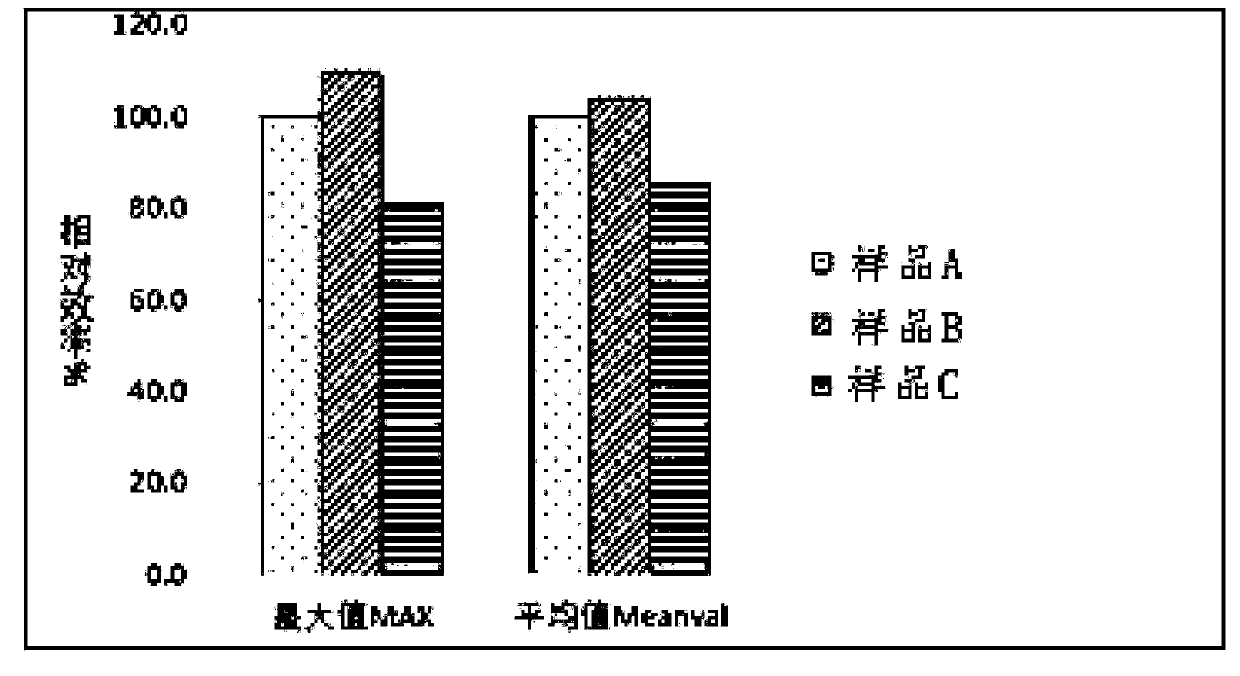

A fully synthetic, cutting fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of low pass rate of sapphire surface roughness, slow settling of glass powder in the liquid tank, and workers' skin allergies, etc., to achieve excellent glass powder Sedimentation performance, excellent resistance to glass powder hardening performance, and the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A fully synthetic cutting fluid for sapphire processing, comprising the following components by weight:

[0031] 69.1 parts by weight of water, 18 parts by weight of pH buffering agent, 0.5 parts by weight of benzotriazole, 4 parts by weight of solubilizer, 8 parts by weight of special lubricant, 0.2 parts by weight of sedimentation agent and 0.2 parts by weight of Alcohol wetting and dispersing agent.

[0032] Wherein, the pH buffer includes the following components by weight: 20 parts by weight of monoethanolamine, 30 parts by weight of triethanolamine and 50 parts by weight of boric acid, and the preparation method of the pH buffer is as follows:

[0033] The monoethanolamine, triethanolamine and boric acid in the above parts by weight were successively added into the reaction kettle, and stirred at 55° C. for 2 hours.

[0034] Wherein, the special lubricant is formed by mixing water-based polymer polyether and glycerin, and the special lubricant includes the follow...

Embodiment 2

[0041] A fully synthetic cutting fluid for sapphire processing, comprising the following components by weight:

[0042] 51.5 parts by weight of water, 25 parts by weight of pH buffering agent, 0.9 parts by weight of benzotriazole, 7 parts by weight of solubilizer, 15 parts by weight of special lubricant, 0.4 parts by weight of sedimentation agent and 0.2 parts by weight of Alcohol wetting and dispersing agent.

[0043] Wherein, the pH buffering agent comprises the following components by weight: 10 parts by weight of monoethanolamine, 70 parts by weight of triethanolamine and boric acid of 20 parts by weight, and the preparation method of the pH buffering agent is as follows:

[0044] The above weight parts of monoethanolamine, triethanolamine and boric acid were sequentially added into the reaction kettle, and stirred at 68° C. for 2 hours.

[0045] Wherein, the special lubricant is formed by mixing water-based polymer polyether and glycerin, and the special lubricant includ...

Embodiment 3

[0052] A fully synthetic cutting fluid for sapphire processing, comprising the following components by weight:

[0053] 39.6 parts by weight of water, 30 parts by weight of pH buffering agent, 0.6 parts by weight of benzotriazole, 9 parts by weight of solubilizer, 20 parts by weight of special lubricant, 0.4 parts by weight of sedimentation agent and 0.4 parts by weight of Alcohol wetting and dispersing agent.

[0054] Wherein, the pH buffer comprises the following components by weight: 30 parts by weight of monoethanolamine, 40 parts by weight of triethanolamine and 30 parts by weight of boric acid, and the preparation method of the pH buffer is as follows:

[0055] The monoethanolamine, triethanolamine and boric acid in the above parts by weight were successively added into the reaction kettle, and stirred at 80° C. for 2 hours.

[0056] Wherein, the special lubricant is formed by mixing water-based polymer polyether and glycerin, and the special lubricant includes the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com