Magnetic composite film for magnetic storage as well as preparation method of magnetic composite film

A composite film and magnetic storage technology, applied in the direction of coated magnetic layer, magnetic recording layer, disc carrier manufacturing, etc., can solve problems affecting the magnetization and interference of perpendicular magnetic recording media, achieve enhanced recording capability and reproduction efficiency, and improve The effect of storage density and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

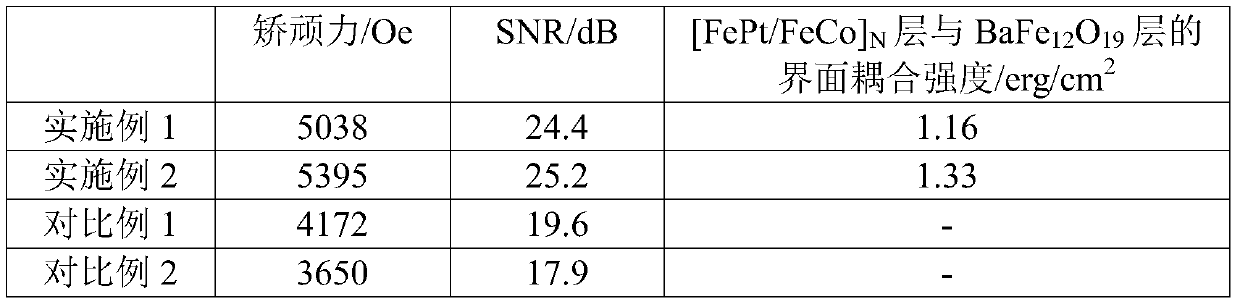

Embodiment 1

[0022] A magnetic composite film for magnetic storage: the magnetic composite film uses a nonmagnetic silicon wafer as a substrate, and a 15nm manganese zinc ferrite soft magnetic layer, an alloy hard magnetic layer, and a 20nm barium ferrite hard magnetic layer are sequentially arranged on its surface ; The alloy hard magnetic layer is [FePt / FeCo] with perpendicular magnetic anisotropy 3 Composite film layer, wherein the molar ratio of Fe and Pt in the FePt alloy layer is 1:0.5, the thickness of the single-layer FePt alloy layer is 4.5nm, the molar ratio of Fe and Co in the FeCo alloy layer is 1:1, and the single-layer FeCo alloy layer The layer thickness was 3 nm.

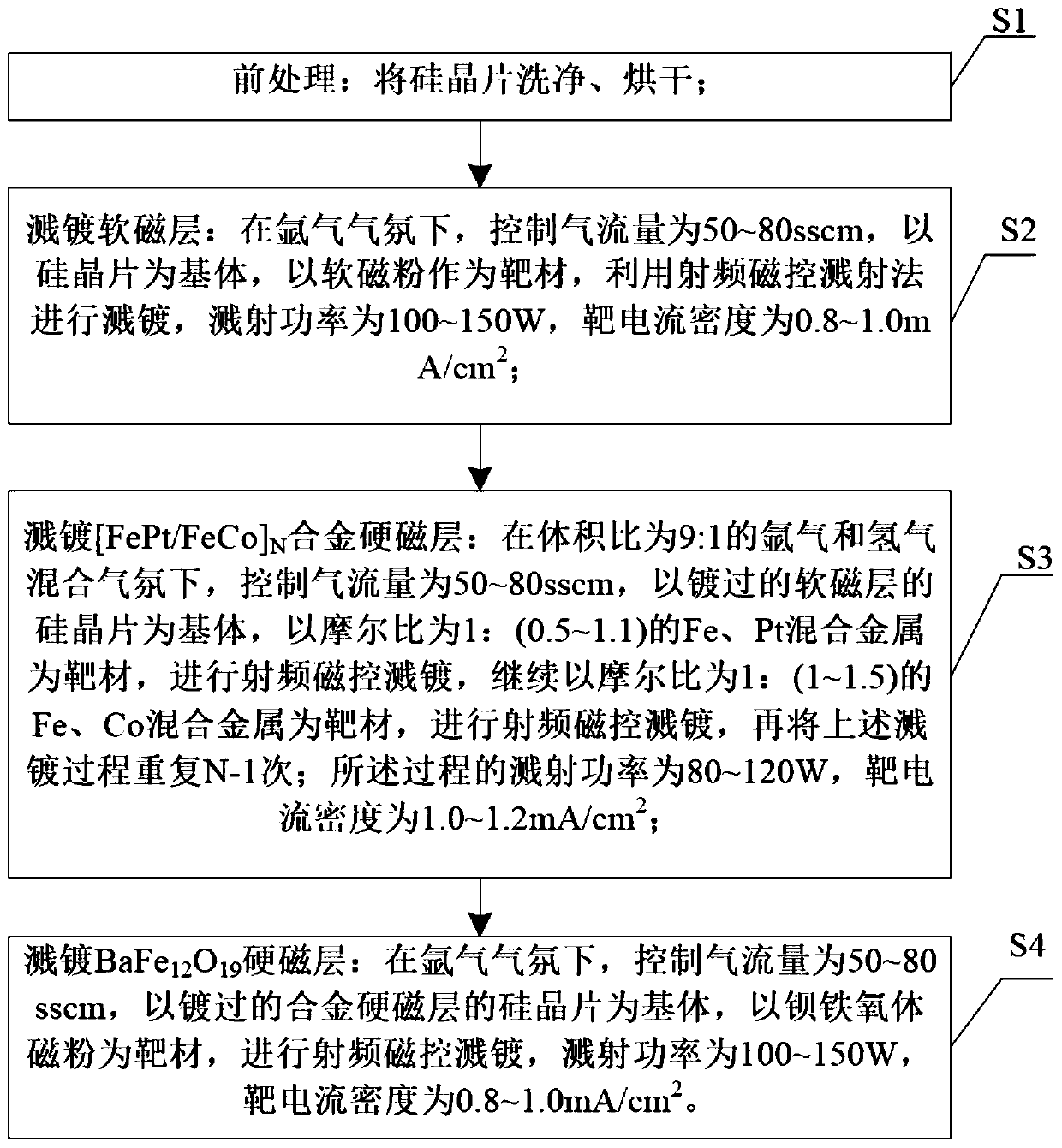

[0023] A method for preparing a magnetic composite film for magnetic storage, comprising the following steps:

[0024] S1: Pretreatment: washing and drying the silicon wafer;

[0025] S2: Sputtering soft magnetic layer: In an argon atmosphere, control the gas flow rate to 50sscm, use silicon wafer as the substr...

Embodiment 2

[0029] A magnetic composite film for magnetic storage: the magnetic composite film uses a non-magnetic silicon wafer as a substrate, and a 20nm manganese zinc ferrite soft magnetic layer, an alloy hard magnetic layer, and a 25nm barium ferrite hard magnetic layer are successively arranged on the surface of the magnetic composite film ; The alloy hard magnetic layer is [FePt / FeCo] with perpendicular magnetic anisotropy 5 Composite film layer, wherein the molar ratio of Fe and Pt in the FePt alloy layer is 1:1.1, the thickness of the single-layer FePt alloy layer is 3nm, the molar ratio of Fe and Co in the FeCo alloy layer is 1:1.5, and the single-layer FeCo alloy layer The thickness is 1.5nm.

[0030] A method for preparing a magnetic composite film for magnetic storage, comprising the following steps:

[0031] S1: Pretreatment: washing and drying the silicon wafer;

[0032] S2: Sputtering soft magnetic layer: In an argon atmosphere, control the gas flow rate to 50-80sscm, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com