Copolymer fiber with higher breaking strength and preparation process of copolymer fiber

A technology for the preparation of copolymerized fibers, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of low strength, inconvenient use, and fracture of copolymerized fibers, and achieve high storage modulus and loss modulus , low loss tangent, and good low temperature service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

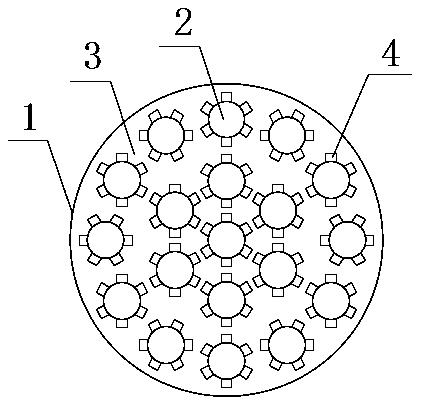

[0027] A copolymer fiber with higher breaking strength and its preparation process, comprising: a fiber body 1, the fiber body 1 is formed by bundling several fiber monofilaments 2, and the outer wall surface of the fiber monofilaments 2 is provided with a raised portion 4. There is a gap 3 between two adjacent fiber monofilaments 2;

[0028] Wherein, the composition and content (percentage by weight) of the fiber monofilament 2 are: PA666 chip 50%-80%, nylon 66 salt 4%-8%.

[0029] Wherein, the protruding parts 4 are uniformly distributed on the surface of the fiber monofilament 2 at intervals, and the protruding parts 4 have a rectangular structure.

[0030] Wherein, the PA666 chips are prepared from PA666 resin through a two-step process of melt spinning and post-drawing. The combination of PA666 segments is:

[0031] .

Embodiment 2

[0033] A kind of preparation technology of the copolymer fiber with higher breaking strength, comprises the following steps:

[0034] S1. Preparation of PA666 slices: first, PA666 resin slices are prepared by melt spinning-post-drawing two-step method to obtain PA666 resin slices;

[0035] S2. Drying: fully dry the PA666 resin slices prepared above in a JM-500ZDGX vacuum drum oven;

[0036] S3, Melt spinning: Subsequently, put the dried PA666 resin slice and nylon 66 salt into the nanocomposite fiber melt spinning forming test equipment, and carry out the melt spinning experiment on the PA666 resin slice through the nanocomposite fiber melt spinning forming test equipment;

[0037] S4. Drafting: Finally, the post-drawing process is completed in the drafting machine, and the PA666 copolymerized fiber can be obtained.

[0038] Among them, in step S2, the drying procedure is to first vacuum dry at 65 °C and pre-crystallize for 10 h, then raise the temperature to 95 °C for 8 h to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com