Preparation method of lithium ion battery composite positive electrode material

A composite positive electrode material and lithium-ion battery technology, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of reduced cycle stability and service life, insufficient bonding, etc., and achieve accelerated reaction rate and completeness of reaction , maintain stability, and improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

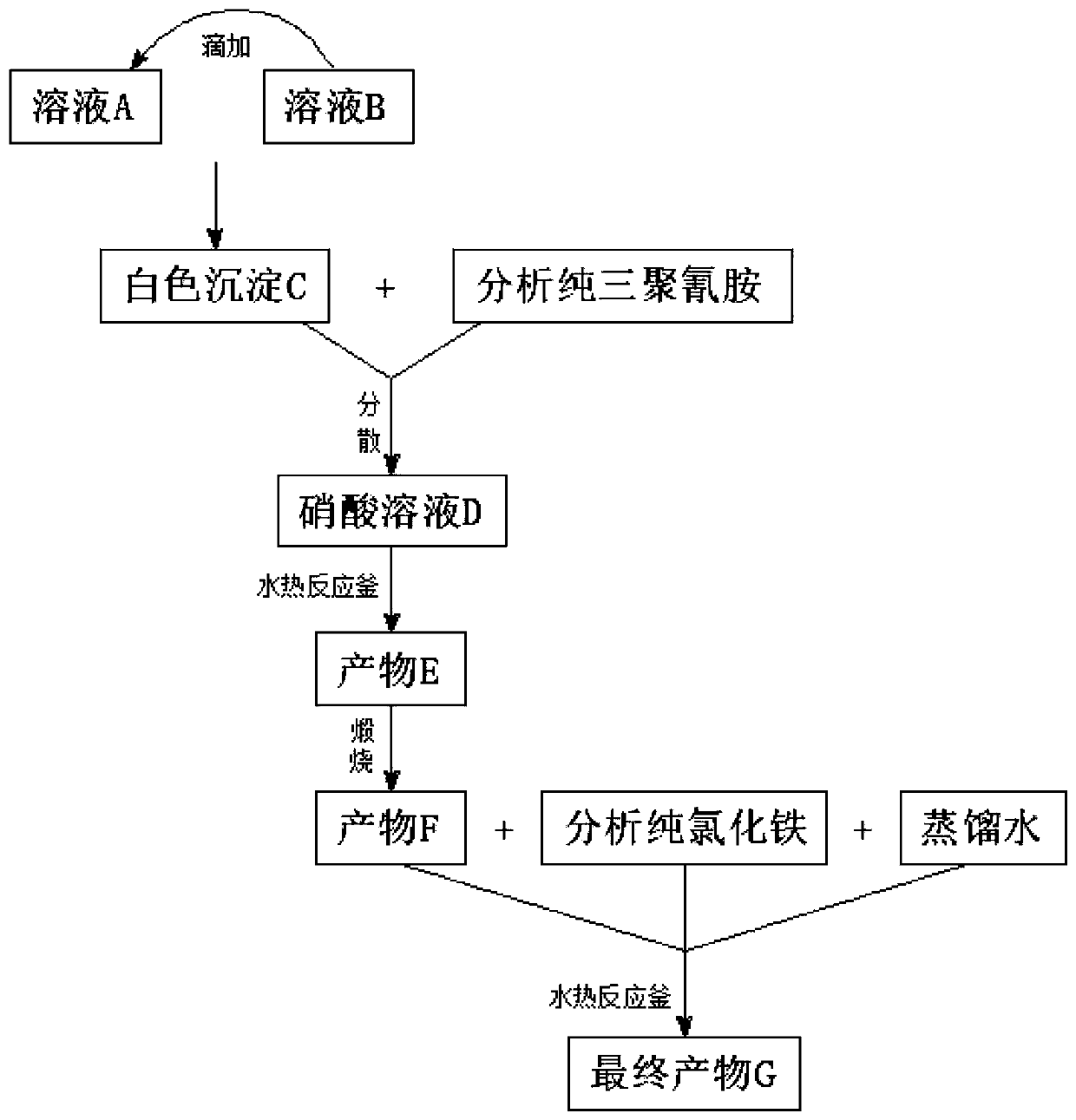

[0048] See figure 1 , A method for preparing a composite cathode material for a lithium ion battery, comprising the following steps:

[0049] S1. Weigh 18 g of analytically pure ferrous nitrate and dissolve it in 50 mL of distilled water to obtain solution A;

[0050] S2. Take 20 mL of analytical pure phosphoric acid and add 40 mL of distilled water to obtain a diluted phosphoric acid solution B;

[0051] S3. Add solution B to solution A dropwise, stir while dripping, centrifuge the resulting precipitate and wash it with distilled water 3 times, and dry it in an oven at 60°C to obtain a white precipitate C;

[0052] S4. Take 30 mL of analytically pure nitric acid and add distilled water to dilute to 100 mL to obtain nitric acid solution D;

[0053] S5. Mix analytically pure melamine and white precipitate C at a mass ratio of 1:1 and then disperse them in solution D. Control the mass ratio of solid phase substance and nitric acid solution to 0.8:1, stir for 10 minutes and place in a hydr...

Embodiment 2

[0057] See figure 1 , A method for preparing a composite cathode material for a lithium ion battery, comprising the following steps:

[0058] S1. Weigh 9g of analytically pure ferrous nitrate and dissolve it in 100mL of distilled water to obtain solution A;

[0059] S2. Take 15 mL of analytically pure phosphoric acid and add 50 mL of distilled water to obtain a diluted phosphoric acid solution B;

[0060] S3. Add solution B to solution A dropwise, stir while dripping, centrifuge the resulting precipitate and wash it with distilled water 3 times, and dry it in an oven at 60°C to obtain a white precipitate C;

[0061] S4. Take 30 mL of analytically pure nitric acid and add distilled water to dilute to 100 mL to obtain nitric acid solution D;

[0062] S5. Mix analytically pure melamine and white precipitate C at a mass ratio of 3:1 and then disperse them in solution D. Control the mass ratio of solid phase substance and nitric acid solution to 0.8:1, stir for 10 minutes and place in a hydr...

Embodiment 3

[0066] See figure 1 , A method for preparing a composite cathode material for a lithium ion battery, comprising the following steps:

[0067] S1. Weigh 11g of analytically pure ferrous nitrate and dissolve it in 80mL of distilled water to obtain solution A;

[0068] S2. Take 15 mL of analytical pure phosphoric acid and add 45 mL of distilled water to obtain a diluted phosphoric acid solution B;

[0069] S3. Add solution B to solution A dropwise, stir while dripping, centrifuge the resulting precipitate and wash it with distilled water 3 times, and dry it in an oven at 60°C to obtain a white precipitate C;

[0070] S4. Take 30 mL of analytically pure nitric acid and add distilled water to dilute to 100 mL to obtain nitric acid solution D;

[0071] S5. Mix analytically pure melamine and white precipitate C at a mass ratio of 1:1 and then disperse them in solution D. Control the mass ratio of solid phase substance and nitric acid solution to 0.8:1.1, stir for 10 minutes and place in a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com