Heat-conducting powder modifier, heat-conducting silica gel and preparation methods thereof

A heat-conducting powder and modifier technology, applied in chemical instruments and methods, organic silicon compounds, heat-exchange materials, etc., can solve the problems of silicone oil precipitation, poor extrudability, and colloid hardening, and achieve oil absorption value. Stable, fast curing, stable production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

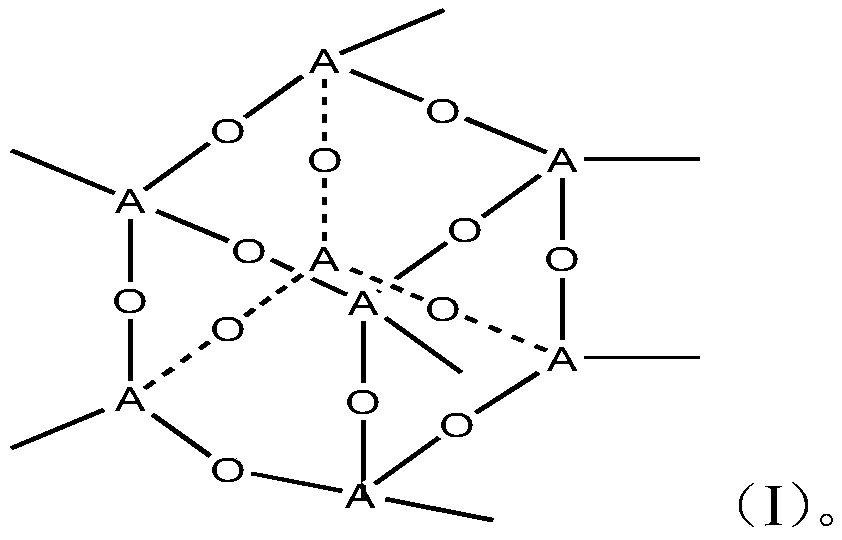

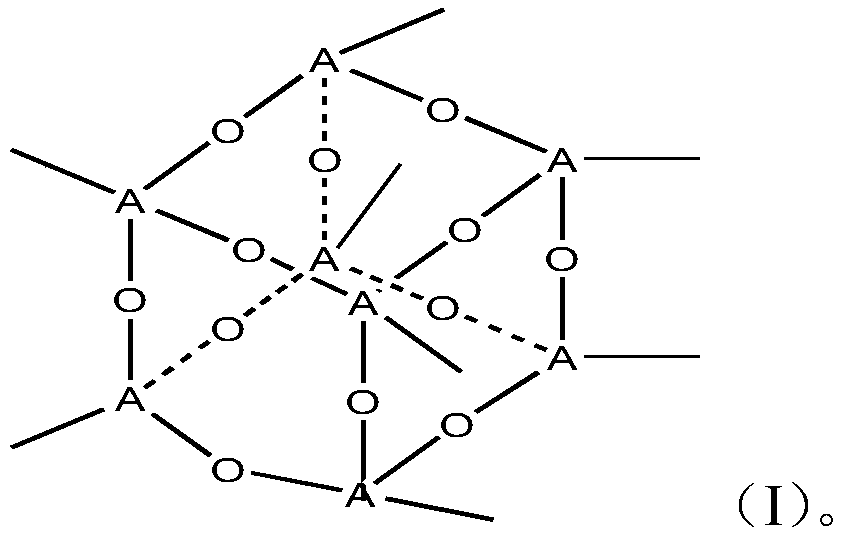

[0036]Referring to Table 1, according to the amount of Examples 1A-12A, the catalyst is dissolved in ethanol to obtain a catalyst solution, the amount of the solvent can be dissolved in the catalyst, the organosilicon precursor and the organotitanium precursor are mixed and then added to the catalyst solution. Stir at 25-30°C for 20-24 hours, then heat up to 60-70°C and stir for 5-8 hours, then filter with suction to remove insoluble matter in the reaction system, use a rotary evaporator to rotate the filtrate to remove excess solvent, Then cool down to obtain a heat-conducting powder modifier, which is put into corresponding reagent bottles for standby.

[0037] Taking Example 1A in Table 1 as an example, the purified heat-conducting powder modifier was prepared by KBr tablet method, and tested on an infrared spectrometer with a scanning range of 4000-400cm -1 , with a resolution of 4cm -1 , the number of scans is 32 times. Fourier transform infrared spectrum (not listed) a...

experiment example 2

[0039] Referring to Table 2, the thermally conductive powder modifiers prepared in Examples 1A-12A were added to the ball mill pot according to the proportions in Table 2, and ball milled at 150 rpm for at least 1 hour to obtain the samples of Examples B1-B12. Modified thermal conductive powder. The modified thermally conductive powders in Comparative Example 1' and Comparative Example 2' are obtained by ball milling with ordinary modifier A171 coupling agent and KH560 coupling agent at 150 rpm for at least 1 hour. thermally conductive powder.

[0040] Among them, the oil absorption value test is carried out on the modified heat-conducting powder obtained in Examples B1-B12 and Comparative Example 1' and Comparative Example 2'. The test method is: put 5.0 g of the powder to be tested on a glass plate, drop Add dioctyl phthalate (DOP) for titration, grind and press with a ink knife to make it into agglomerates. The calculation method of oil absorption value is: oil absorption...

experiment example 3

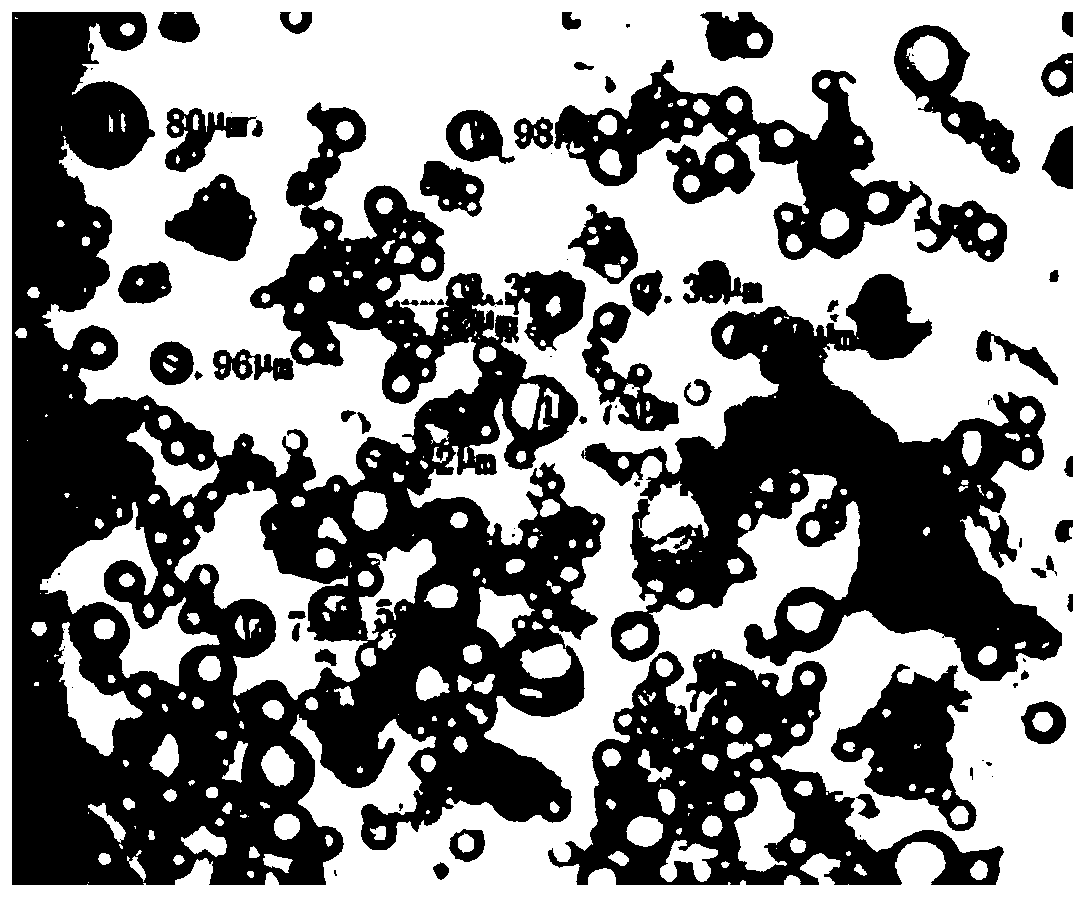

[0043] Referring to Table 4, weigh each component according to the amount of components in Examples C1-C12 and Comparative Example 1-2 in Table 4, and add each component to a vacuum kneader with a heating jacket, at 20-30°C Stir evenly; then heat the heat-conducting oil in the heating jacket, and start the vacuum pump to vacuum the inside of the vacuum kneader at the same time, and continue stirring for 60-90 minutes to obtain a semi-finished silicone gel; Grinding; the fineness of the semi-finished silicone gel after grinding is less than 20 μm; the ground semi-finished silicone gel is added to a vacuum kneader with a heating jacket, and then the heat-conducting oil in the heating jacket is heated to 60-90 ° C, and at the same time Start the vacuum machine to evacuate the inside of the vacuum kneader, and stir for 20-30 minutes to obtain an ultra-low thermal resistance thermal conductive silicone gel.

[0044] Referring to Table 5 and Table 6, it can be seen from the results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com