Cobalt phosphide loaded heteroatom doped porous carbon material as well as preparation method and application thereof

A porous carbon material, cobalt phosphide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as complex processes, achieve clean preparation process, high repeatability, avoidance of The effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

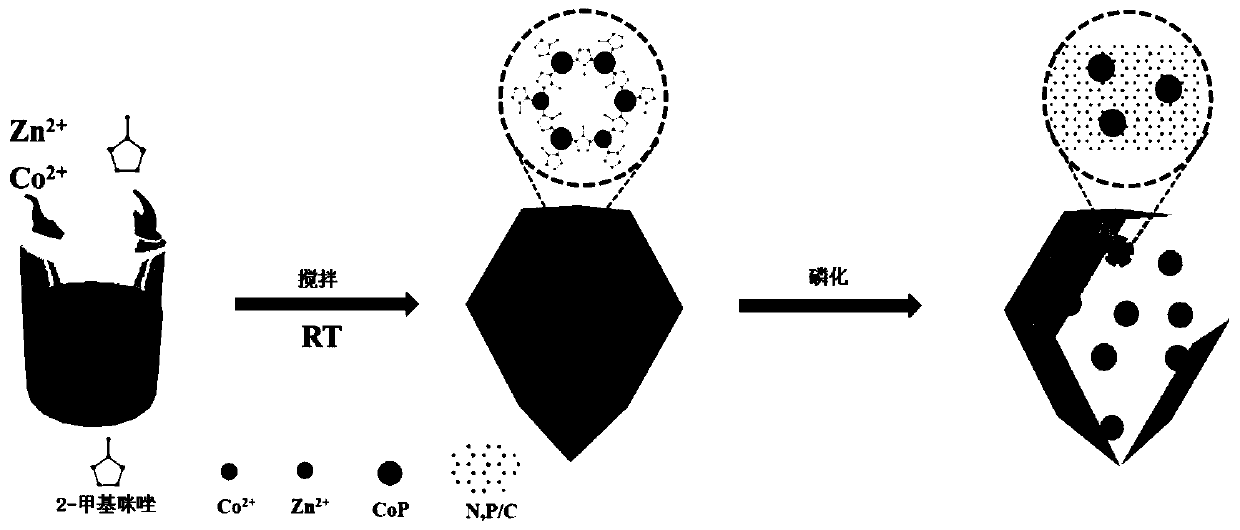

[0037] A preparation method of cobalt phosphide / nitrogen phosphorus doped porous carbon material with bifunctional catalytic activity, such as figure 1 As shown, the specific preparation steps are as follows:

[0038] Step 1: Weigh 23g of 2-dimethylimidazole, add 80mL of deionized water, and stir magnetically until 2-dimethylimidazole is completely dissolved;

[0039] Step 2: Add 1.2 g of cobalt nitrate hexahydrate and zinc nitrate hexahydrate (the molar mass ratio of Zn to Co is 1:1) into 10 ml of deionized water, and keep stirring to completely dissolve it to obtain a metal salt solution;

[0040]Step 3: Under the condition of magnetic stirring, slowly add the metal salt solution obtained in step 2 to the solution obtained in step 1, a precipitate is formed instantly, and the mixed solution is continuously stirred for 2 hours.

[0041] Step 4: Centrifuge the mixed solution containing the precipitate obtained in Step 3 at a speed of 10000 rpm. The sediment in the lower laye...

Embodiment 2

[0045] A preparation method of cobalt phosphide / nitrogen phosphorus doped porous carbon material with bifunctional catalytic activity, such as figure 1 As shown, the specific preparation steps are as follows:

[0046] Step 1: Weigh 23g of 2-dimethylimidazole, add 80mL of deionized water, and stir magnetically until 2-dimethylimidazole is completely dissolved;

[0047] Step 2: Add 1.2 g of cobalt nitrate hexahydrate and zinc nitrate hexahydrate (the molar mass ratio of Zn to Co is 3:1) into 10 ml of deionized water, and keep stirring to completely dissolve it to obtain a metal salt solution;

[0048] Step 3: Under the condition of magnetic stirring, slowly add the metal salt solution obtained in step 2 to the solution obtained in step 1, a precipitate is formed instantly, and the mixed solution is continuously stirred for 2 hours.

[0049] Step 4: Centrifuge the mixed solution containing the precipitate obtained in Step 3 at a speed of 10000 rpm. The sediment in the lower lay...

Embodiment 3

[0053] A preparation method of cobalt phosphide / nitrogen phosphorus doped porous carbon material with bifunctional catalytic activity, such as figure 1 As shown, the specific preparation steps are as follows:

[0054] Step 1: Weigh 23g of 2-dimethylimidazole, add 80mL of deionized water, and stir magnetically until 2-dimethylimidazole is completely dissolved;

[0055] Step 2: Add 1.2 g of cobalt nitrate hexahydrate and zinc nitrate hexahydrate (the molar mass ratio of Zn to Co is 1:3) into 10 ml of deionized water, and keep stirring to completely dissolve it to obtain a metal salt solution;

[0056] Step 3: Under the condition of magnetic stirring, slowly add the metal salt solution obtained in step 2 to the solution obtained in step 1, a precipitate is formed instantly, and the mixed solution is continuously stirred for 2 hours.

[0057] Step 4: Centrifuge the mixed solution containing the precipitate obtained in Step 3 at a speed of 10000 rpm. The sediment in the lower lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com