High-filling-capacity polytetrafluoroethylene composite film and preparation method thereof

A polytetrafluoroethylene and composite film technology, which is applied in the field of high-filling polytetrafluoroethylene composite film and its preparation, can solve the problem of weakening the structural uniformity and mechanical properties of the PTFE composite film, and cannot realize the high-filling PTFE composite film and resin. Due to the low degree of particle infiltration and coating, the effect of dense and defect-free structure, reduced sintering time and smooth surface can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

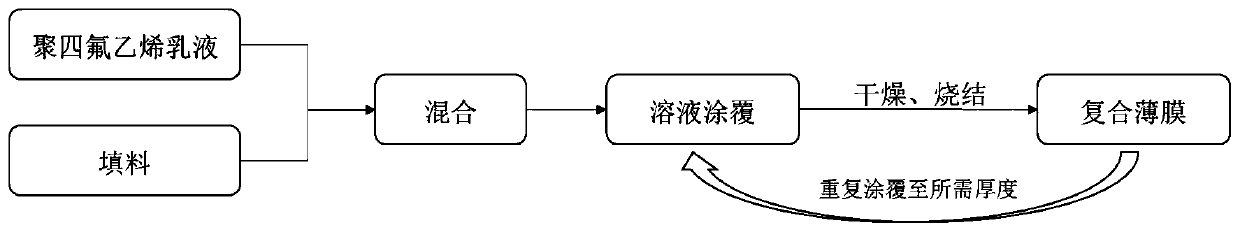

[0038] The present invention also provides a method for preparing a high-fill polytetrafluoroethylene composite film, comprising the steps of:

[0039] (1) mixing raw materials except the filler to obtain a polytetrafluoroethylene composite dispersion, then adding filler to obtain a compound;

[0040] (2) using the mixture to coat a layer of thin film, followed by drying and sintering to obtain a coating;

[0041] (3) Repeat step (2) on the surface of the resulting coating until the high-filling polytetrafluoroethylene composite film is obtained.

[0042] When the present invention prepares the polytetrafluoroethylene composite film with a high filling amount, the raw materials except the filler are first mixed to obtain the polytetrafluoroethylene composite dispersion liquid, and then the filler is added to the polytetrafluoroethylene composite dispersion liquid to obtain the mixture .

[0043]After the mixture is prepared in the present invention, a layer of film is first ...

Embodiment 1

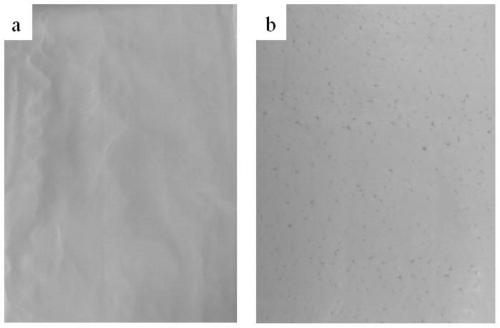

[0049] Take 100 parts of 0.3μm 60wt% polytetrafluoroethylene dispersion and 2 parts of dispersant, 2 parts of active agent, 1 part of modifier, 2 parts of stabilizer, 1 part of leveling agent, 1 part of defoamer, 1 part of The antioxidants are mixed to obtain a polytetrafluoroethylene composite dispersion, and then the polytetrafluoroethylene composite dispersion is mixed with 100 parts of fillers to obtain a compound. The filler used in this example is a mixed filler mixed with inorganic filler, organic filler and metal particles at a mass ratio of 1:1:2, wherein the inorganic filler is glass fiber, the organic filler is polyphenylene ether, and the metal particle is iron powder. Use this mixture to coat a film, first dry at 60°C for 20 minutes, and then sinter at 360°C for 30 minutes to obtain a layer of coating. The coating has a thickness of 40 μm. Repeat coating once on the surface of the obtained coating to prepare a polytetrafluoroethylene composite film with a thickne...

Embodiment 2

[0052] Take 100 parts of 0.2 μm 60wt% polytetrafluoroethylene dispersion and 2 parts of dispersant, 2 parts of active agent, 2 parts of modifier, 2 parts of stabilizer, 1 part of leveling agent, 1 part of defoamer, 1 part of The antioxidants were mixed to obtain a polytetrafluoroethylene composite dispersion, and then the polytetrafluoroethylene composite dispersion was mixed with 150 parts of fillers to obtain a compound. The filler used in this example is a mixed filler mixed with inorganic filler, organic filler and metal particles according to the mass ratio of 3:2:1, wherein the inorganic filler is a mixture of alumina and silica, the organic filler is polyarylsulfone, and the metal particle The particles are mixed with copper powder and aluminum powder. Use this mixture to coat a film, first dry at 100°C for 8 minutes, and then sinter at 380°C for 60 minutes to obtain a layer of coating. The coating has a thickness of 40 μm. Repeat the coating step once on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com