Anti-dewing coating and preparation method thereof

An anti-condensation and coating technology, applied in the direction of coating, etc., can solve the problem that the adhesion between the anti-condensation coating and the surface of the adhered base layer is reduced, the "air tightness" effect of the coating is reduced, and the coating and the adhered base layer are reduced. The surface is prone to detachment and other problems, to achieve the effect of enhancing adhesion and reducing the possibility of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

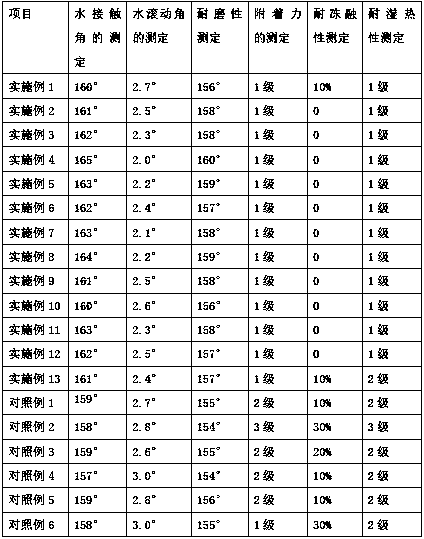

Examples

Embodiment 1- Embodiment 5

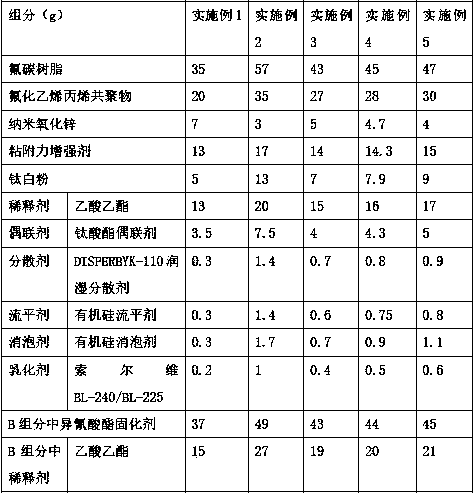

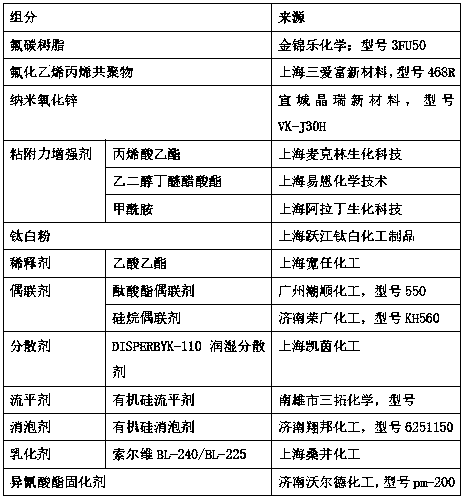

[0070] The raw material components and the preparation method of the anti-condensation coating in embodiment 1-embodiment 5 are all the same, and the difference is that the dosage of each component is different, specifically see Table 1:

[0071]

[0072] In embodiment 1-embodiment 5, adhesion enhancer is all made up of ethyl acrylate, ethylene glycol butyl ether acetate and formamide, the weight proportion of ethyl acrylate, ethylene glycol butyl ether acetate and formamide It is 2:2.3:2.7; the particle size of nano zinc oxide is 20nm.

[0073] Taking Example 4 as an example, the preparation method of the anti-condensation coating is described, including the following steps:

[0074] Prepare component A:

[0075] S1. According to the proportion, firstly mix the nano-zinc oxide, dispersant and coupling agent, the stirring speed is 650r / min, and stir for 50min to obtain the primary mixture;

[0076] S2. Add fluorocarbon resin, fluorinated ethylene propylene copolymer, tita...

Embodiment 6

[0080] The difference between this example and Example 4 is only that the weight ratio of ethyl acrylate, ethylene glycol butyl ether acetate and formamide is 1:3:2.6.

Embodiment 7

[0082] The difference between this example and Example 4 is only that the weight ratio of ethyl acrylate, ethylene glycol butyl ether acetate and formamide is 2.5:2.5:3.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com