Treatment process of sodium chlorate chromium-containing salt mud

A treatment process, sodium chlorate technology, applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of complex process, inability to completely remove, ecological environment pollution, etc., and achieve simple process steps , Reduce equipment investment cost, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

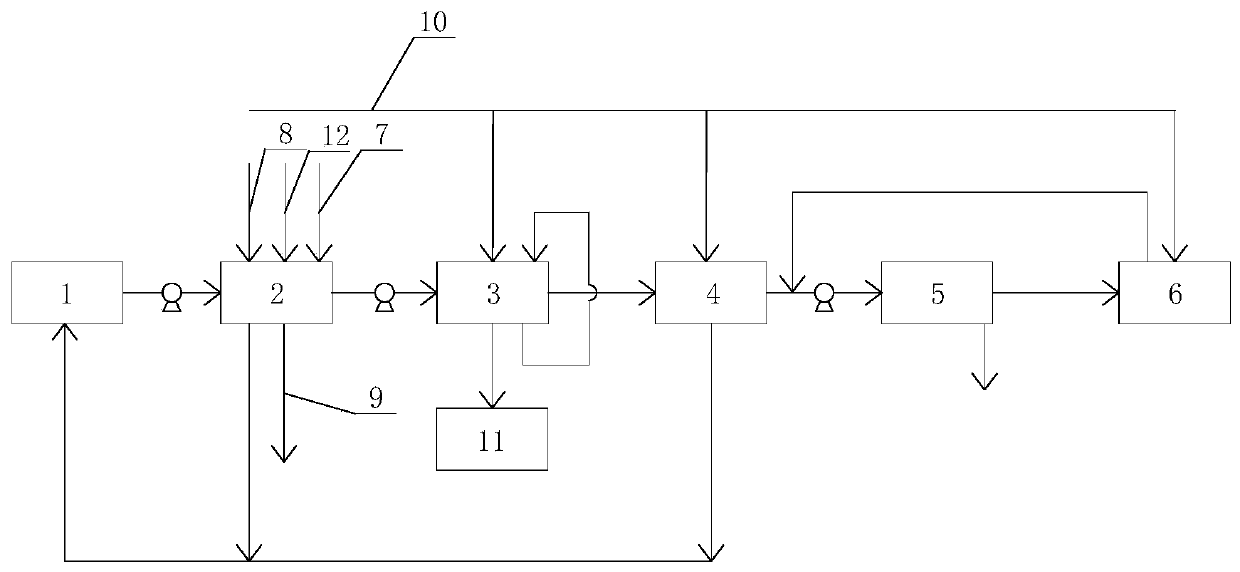

[0027] Embodiment 1: as figure 1 Shown, a kind of treatment system of sodium chlorate containing chromium salt mud, it comprises the first material tank 1, reactor 2, filter 3, the second material tank 4, centrifuge 5 and the 3rd material tank 6 , The present embodiment filter 3 is a belt vacuum filter. The outlet of the first chemical material tank 1 is connected with the inlet of the batching pump by a pipeline, and the outlet of the batching pump is connected with the feed inlet of the reactor 2 by a pipeline; the reactor 2 is provided with a hydrochloric acid inlet 7; the steam pipeline 8 The outlet is connected with the steam inlet of the reactor 2, and the condensed water outlet of the reactor 2 is connected with the water inlet of the first material tank 1 through a pipeline; the outlet of the cooling water inlet pipeline 12 is connected with the cooling water inlet of the reactor 2, and the reaction The cooling water return port of kettle 2 is connected with the inlet...

Embodiment 2

[0030] Embodiment 2: Utilize embodiment 1 system, process the technique of sodium chlorate containing chromium salt mud, it comprises the steps: (1) chromium salt mud material; (2) detoxification of chromium mud solution; (3) cleaning and solid-liquid separation; (4) the filter cake is subjected to back dissolution and solid-liquid separation; (5) solid waste detection; wherein,

[0031] (1) Chromium-containing salt mud chemical material: put chromium-containing salt mud and water into the first chemical material tank 1 in proportion to mix, stir and fully dissolve to obtain chromium mud solution; the mass ratio of chromium-containing salt mud to water is 1 :1

[0032] (2) Detoxification of chromium mud solution: put the chromium mud solution into reaction kettle 2, then add hydrochloric acid to the chromium mud solution, heat to 80°C, and keep the temperature for 2 hours to fully react, then naturally cool down to 40°C ℃, the natural cooling process ensures the full growth o...

Embodiment 3

[0036]Embodiment 3: utilize embodiment 1 system, process the technique of sodium chlorate containing chromium salt mud, it comprises the steps: (1) chromium salt mud material; (2) detoxification of chromium mud solution; (3) cleaning and solid-liquid separation; (4) the filter cake is subjected to back dissolution and solid-liquid separation; (5) solid waste detection; wherein,

[0037] (1) Chromium-containing salt mud chemical material: put chromium-containing salt mud and water into the first chemical material tank 1 in proportion to mix, stir and fully dissolve to obtain chromium mud solution; the mass ratio of chromium-containing salt mud to water is 1 : 4

[0038] (2) Detoxification of chromium mud solution: put the chromium mud solution into reaction kettle 2, then add hydrochloric acid to the chromium mud solution, heat to 100°C, and keep the temperature for 1.5 hours to fully react, then naturally cool down to 50 ℃, the natural cooling process ensures the full growth ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap